- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

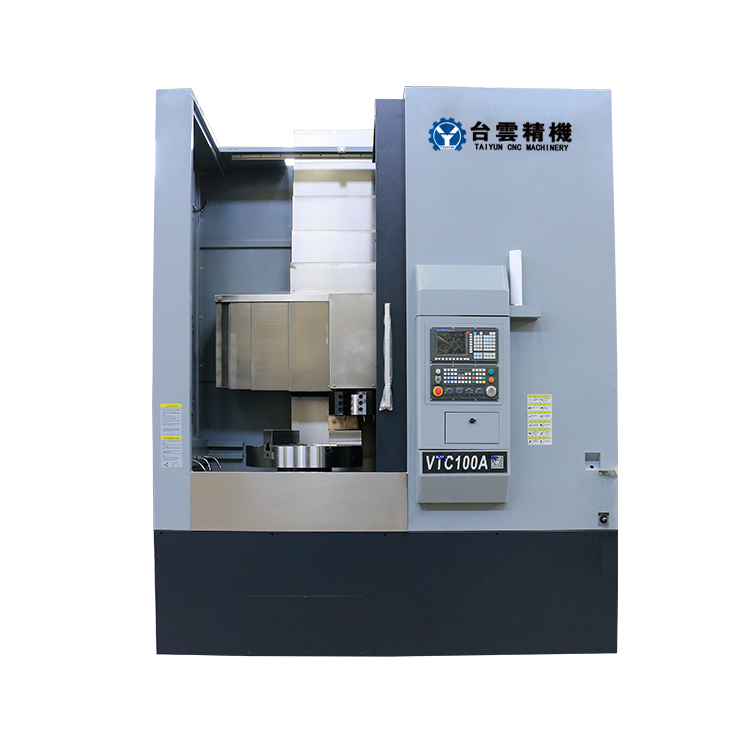

affordable cnc lathe

Compared with high-end models, economical CNC vertical lathes are more suitable for small and medium-sized enterprises or cost-sensitive users....

Compared with high-end models, economical CNC vertical lathes are more suitable for small and medium-sized enterprises or cost-sensitive users. Economical CNC vertical lathes usually have simple designs, intuitive user interfaces and are easy to operate. This is an advantage for companies that do not have excessive CNC experience or technical personnel, and reduces the difficulty of getting started and operating.

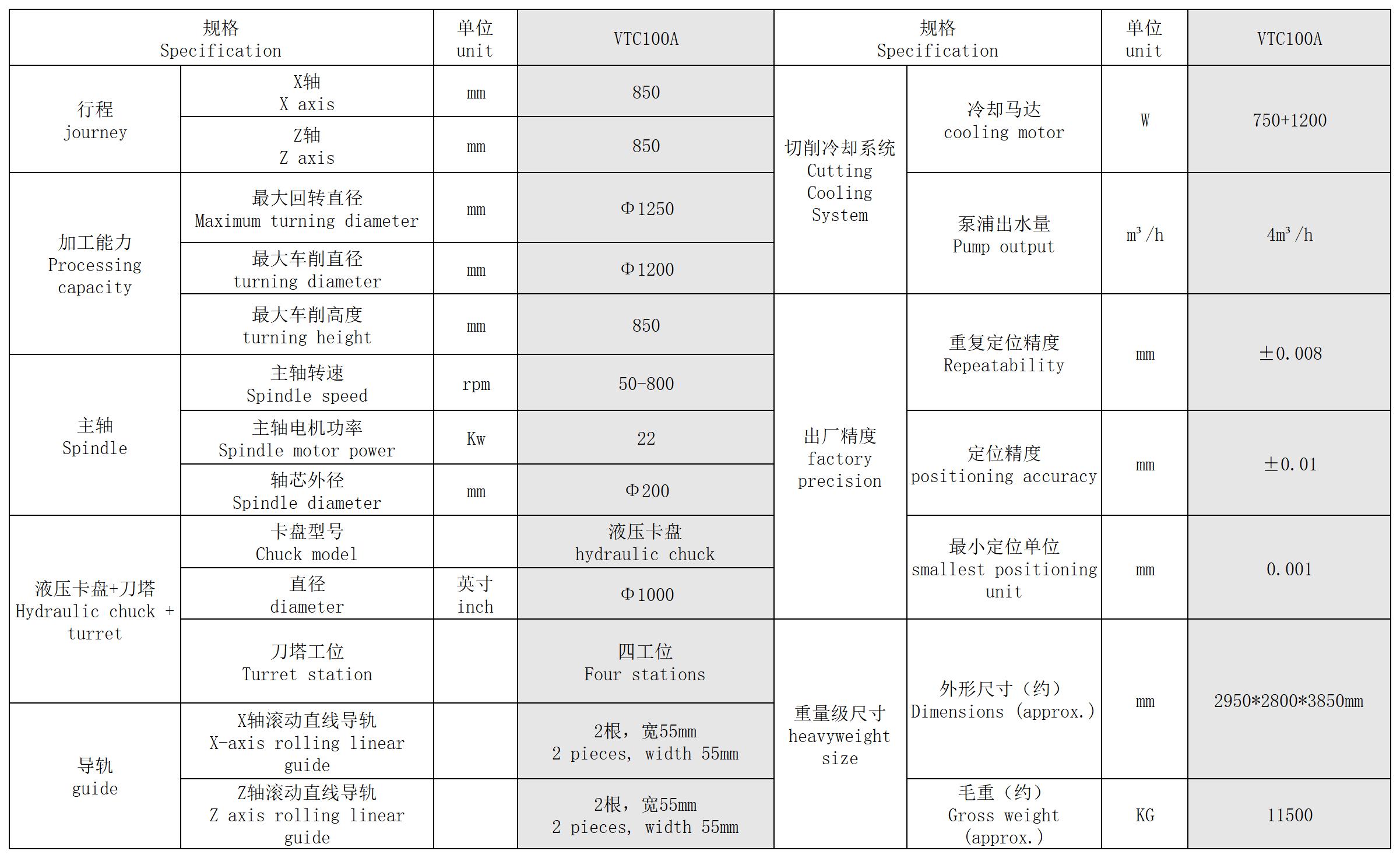

1. Machine tool structure: Choose a CNC vertical lathe with a solid and stable machine tool structure. It usually adopts a heavy-duty machine tool bed design, which can provide good rigidity and stability. This helps reduce vibration and improve cutting accuracy.

2. Spindle design: Powerful cutting capabilities usually require a powerful spindle. When choosing a CNC vertical lathe, pay attention to parameters such as spindle power, speed range, and torque to ensure it meets your heavy cutting needs.

3. Guide rails and ball screws: The use of high-precision guide rails and ball screws can improve the processing accuracy and stability of CNC vertical lathes. Especially during heavy cutting, the quality of these components is critical to machine tool performance.

4. Tool turret and tool magazine: In order to adapt to different cutting needs, choose a CNC vertical lathe with a multi-functional turret or tool magazine. This allows for easy replacement of different types of cutting tools, improving processing flexibility and efficiency.

5. Cooling system: During heavy cutting, a large amount of heat will be generated in the cutting area. A good cooling system can effectively reduce the temperature, ensure the temperature stability of the tool and workpiece, and improve cutting efficiency and workpiece quality.

6. Control system: The stability and accuracy of the CNC system are crucial for heavy cutting. Choose a well-known brand of CNC system to ensure it has good real-time control performance and high-precision motion control.

7. Cutting parameter adjustment: CNC vertical lathes are usually equipped with a variety of cutting parameter adjustment functions, which can be adjusted according to different processing needs to achieve the best cutting effect.

When choosing, it is recommended to consider comprehensively based on specific processing needs, budget and brand reputation. At the same time, understanding after-sales service, training support, etc. are also important considerations when choosing a CNC vertical lathe.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды