- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

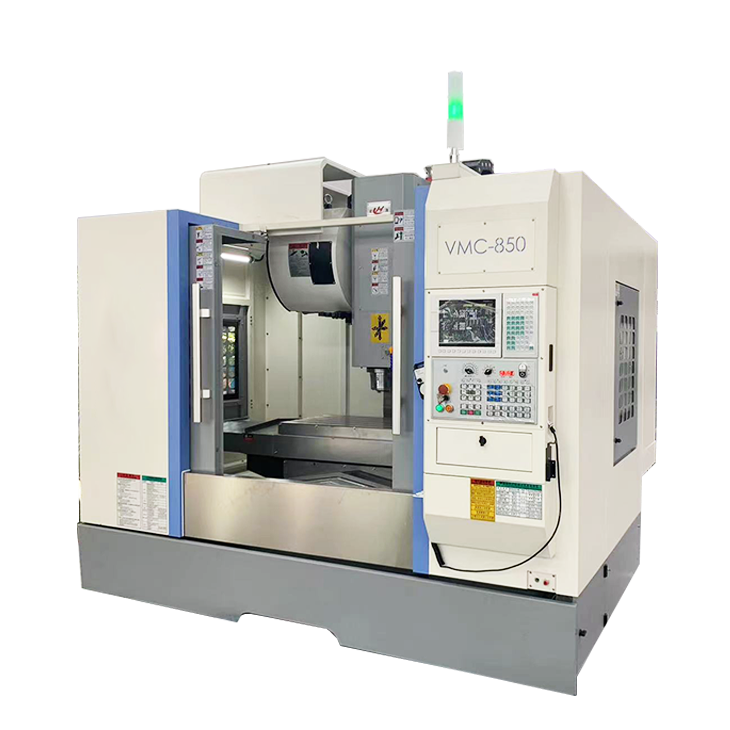

Machining center for complex parts processing

The machining center plays a key role in the processing of complex parts. Its high efficiency, high precision and automation characteristics make it an important equipment in modern manufacturing....

The machining center plays a key role in the processing of complex parts. Its high efficiency, high precision and automation characteristics make it an important equipment in modern manufacturing. Here are some of the main applications of machining centers in complex parts processing:

1. High-precision processing: The machining center has a high-precision control system and advanced cutting technology, which can achieve high-precision processing of complex parts. Whether it is complex-shaped curved surfaces, holes or tiny parts, the machining center can ensure processing accuracy and surface quality.

2. Complex shape processing: For parts with complex shapes, the machining center controls the motion trajectory of the tool through programming, and can complete multiple processes at one time. This makes the processing of complex shapes easier while improving processing efficiency and accuracy.

3. Five-axis machining: The machining center can achieve more dimensional processing and is especially suitable for processing parts with complex curved and inclined surfaces. For example, automobile engine blocks and heads, aerospace parts, ship parts, high-end molds, and medical device parts can all be processed with high precision through five-axis machining centers.

4. Mass production: The machining center is suitable for mass production. It has a high degree of automation and high processing efficiency, which can greatly shorten the production cycle and improve production efficiency. At the same time, due to the improvement of processing accuracy, the scrap rate can be reduced and production costs can be further reduced.

5. Tool library and automatic tool change: Machining centers are usually equipped with a tool library that can automatically select and replace tools, reducing manual intervention and improving the automation of the machining process. This enables the machining center to continuously process multiple processes, further improving production efficiency.

To sum up, the machining center plays an important role in the processing of complex parts. Its high precision, high efficiency, automation and flexibility make it an indispensable and important equipment in modern manufacturing.

| Machine model | VMC650 | VMC840 | VMC850 | VMC855 | VMC966 |

| Workbench size (mm) | 1000X400 | 1000X400 | 1000X500 | 1000X550 | 1100X550 |

| Maximum allowable load (Kg) | 400 | 300 | 500 | 500 | 600 |

| X-axis travel (mm) | 650 | 800 | 800 | 800 | 900 |

| Y-axis travel (mm) | 400 | 400 | 500 | 550 | 600 |

| Z-axis travel (mm) | 550 | 550 | 500 | 550 | 600 |

| T-slot | 3-18-120 | 3-18-140 | 5-18-108 | 5-18-90 | 5-18-100 |

| Distance from spindle center to Z-axis guide surface (mm) | 485 | 445 | 552 | 590 | 663 |

| Distance from spindle end face to worktable surface (mm) | 100-650 | 100-650 | 110-610 | 120-670 | 100-700 |

| Spindle taper hole | BT40-120 | BT40-120 | BT40-140 | BT40-150 | BT40-150 |

| Spindle speed (r/min) | 8000 | 8000 | 8000 | 8000 | 8000 |

| X/Y/Z rapid movement (m/min) | 48/48/48 | 30/30/18 | 48/48/48 | 48/48/48 | 48/48/48 |

| Machine weight (Kg) | 3800 | 3200 | 5300 | 5500 | 5600 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды