- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

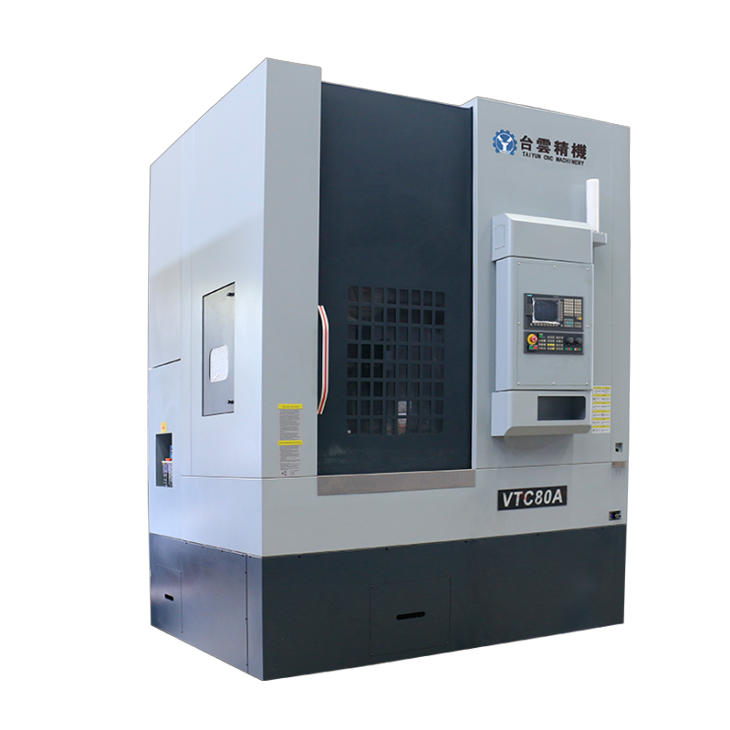

High speed precision wheel hub CNC vertical lathe

High-speed precision wheel hub vertical lathe is a CNC machine tool specially used for processing high-precision wheel hubs....

High-speed precision wheel hub vertical lathe is a CNC machine tool specially used for processing high-precision wheel hubs. This equipment has the ability of high-speed rotation and precision processing, which can meet the high requirements for wheel hub processing accuracy and efficiency.

High-speed precision wheel hub vertical lathe is a vertical lathe mainly used for processing various types of high-precision wheel hubs, such as automobile wheel hubs, motorcycle wheel hubs, etc.

High-speed precision wheel hub vertical lathe achieves precision processing of the wheel hub surface and internal structure through high-speed rotation and precise control of the tool's motion trajectory.

1. Main technical parameters:

Spindle speed: The spindle speed of high-speed precision wheel hub vertical lathe is usually very high, which can reach thousands or even tens of thousands of revolutions per minute to meet the needs of high-speed cutting.

Processing accuracy: High-speed precision wheel hub vertical lathe has extremely high processing accuracy, which can achieve micron-level processing of the wheel hub surface, ensuring that the key indicators such as roundness, flatness and surface roughness of the wheel hub meet the design requirements.

Repeat positioning accuracy: High-speed precision wheel hub vertical lathe has excellent repeat positioning accuracy, which can ensure consistent processing results during multiple processing processes.

2. Features and advantages:

High speed and high efficiency: High-speed precision hub vertical lathe can achieve rapid processing and improve production efficiency through high-speed rotation and fast tool change system.

High precision: High-speed precision hub vertical lathe has extremely high processing accuracy and repeated positioning accuracy, which can ensure the stable and reliable processing quality of the hub.

Easy operation: High-speed precision hub vertical lathe adopts advanced CNC system and operation interface, which makes the equipment easy to operate and easy to learn, and reduces the technical requirements for operators.

Strong flexibility: High-speed precision hub vertical lathe can be flexibly configured and adjusted according to different processing requirements to adapt to different specifications and types of hub processing.

3. Application field:

High-speed precision hub vertical lathe is widely used in automobile manufacturing, motorcycle manufacturing, electric vehicle manufacturing and other fields for processing various types of high-precision hubs.

In the manufacturing of high-end automobiles and motorcycles, high-speed precision hub vertical lathe plays a vital role to ensure the quality and performance of the hub.

4. Market status and development trend:

With the continuous development of the automobile, motorcycle and other transportation manufacturing industries, the requirements for hub processing are getting higher and higher. As one of the important processing equipment, the market demand for high-speed precision wheel hub vertical lathe is increasing.

In the future, with the continuous advancement of manufacturing technology and the improvement of intelligence level, high-speed precision wheel hub vertical lathe will develop in the direction of higher precision, higher efficiency and more intelligence.

| Specification | unit | VTC80A | Specification | unit | VTC80A |

| X axis | mm | 670 | Turret station | Four stations/eight stations | |

| Z axis | mm | 200-1050 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ1000 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ800 | cooling motor | W | 450+750 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.005 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.008 |

| Spindle diameter | mm | Φ180 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*2100*3600mm | |

| diameter | inch | 24″ | Gross weight (approx.) | kg | 9000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды