- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

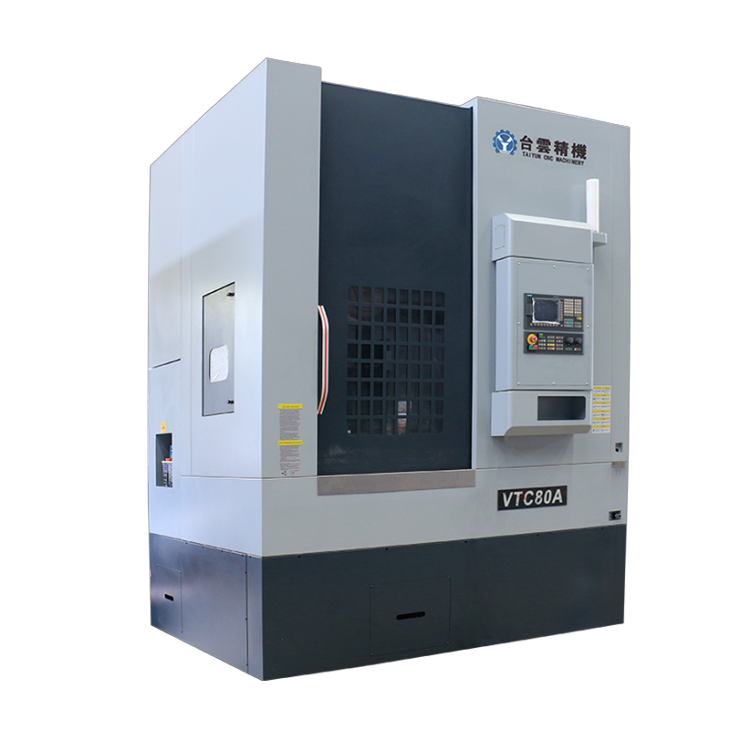

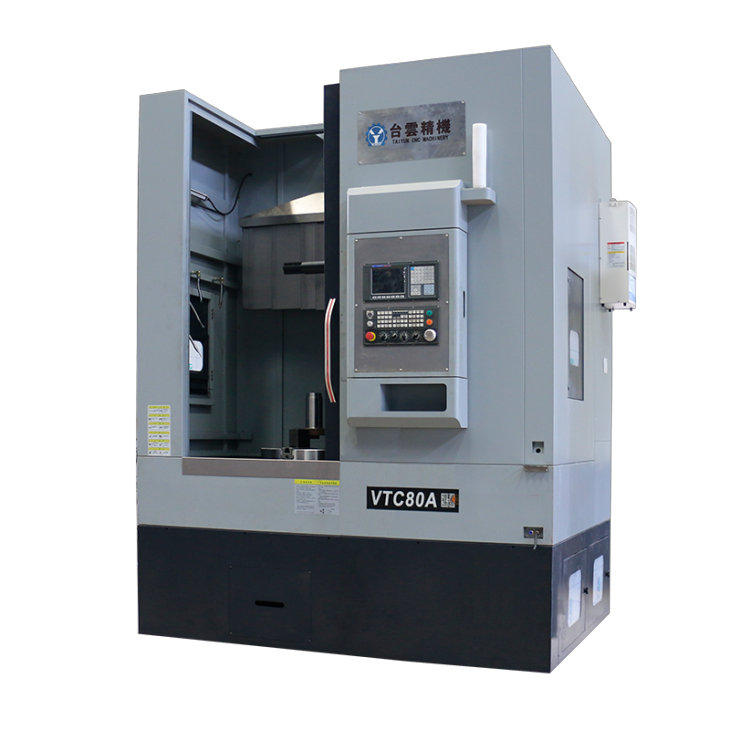

Automated CNC lathe

The automated CNC lathe is a high-performance, high-precision, low-noise machine tool equipment. It controls the movement and processing process of the machine tool through a CNC system, realizing automated processing of parts....

The automated CNC lathe is a high-performance, high-precision, low-noise machine tool equipment. It controls the movement and processing process of the machine tool through a CNC system, realizing automated processing of parts. This kind of automated CNC lathe is widely used in the field of valve processing. Its advantages are mainly reflected in the following aspects:

First of all, automated CNC lathes have excellent processing accuracy and stability. Because the automated CNC lathe adopts advanced CNC technology and high-precision mechanical structure, it can accurately control the movement trajectory and cutting parameters of the tool, thereby ensuring that the processed valve parts have extremely high precision and surface quality.

Secondly, automated CNC lathes improve processing efficiency. Through automated processing, manual intervention and tool changing time are reduced, and the processing speed is greatly improved. At the same time, the automated CNC lathe also has functions such as automatic loading and unloading and automatic tool feeding, which further reduces the difficulty of operation and improves production efficiency.

In addition, automated CNC lathes also have good adaptability and flexibility. Automated CNC lathes can adapt to the processing of valve parts of different specifications and shapes by adjusting CNC programs according to different processing needs. This enables wide application in various valve manufacturing scenarios to meet the needs of different customers.

In the process of valve processing, the application of automated CNC lathes also needs to pay attention to some matters. First of all, it is necessary to select the appropriate machine tool model and configuration to ensure that the processing capacity and accuracy of the automated CNC lathe can meet the requirements of valve processing. Secondly, regular maintenance and upkeep of machine tools is required to ensure the stability and reliability of machine tools. At the same time, operators need to receive professional training and be familiar with the operating procedures and maintenance methods of machine tools to ensure the safe operation and processing quality of machine tools.

In short, automated CNC lathes have broad application prospects and advantages in the field of valve processing. Through reasonable selection, use and maintenance, its characteristics of high precision, high efficiency and high adaptability can be fully utilized to provide strong support for the development of the valve manufacturing industry.

| Specification | unit | VTC80A | Specification | unit | VTC80A |

| X axis | mm | 670 | Turret station | Four stations/eight stations | |

| Z axis | mm | 200-1050 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ1000 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ800 | cooling motor | W | 450+750 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.005 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.008 |

| Spindle diameter | mm | Φ180 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*2100*3600mm | |

| diameter | inch | 24″ | Gross weight (approx.) | kg | 9000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды