- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

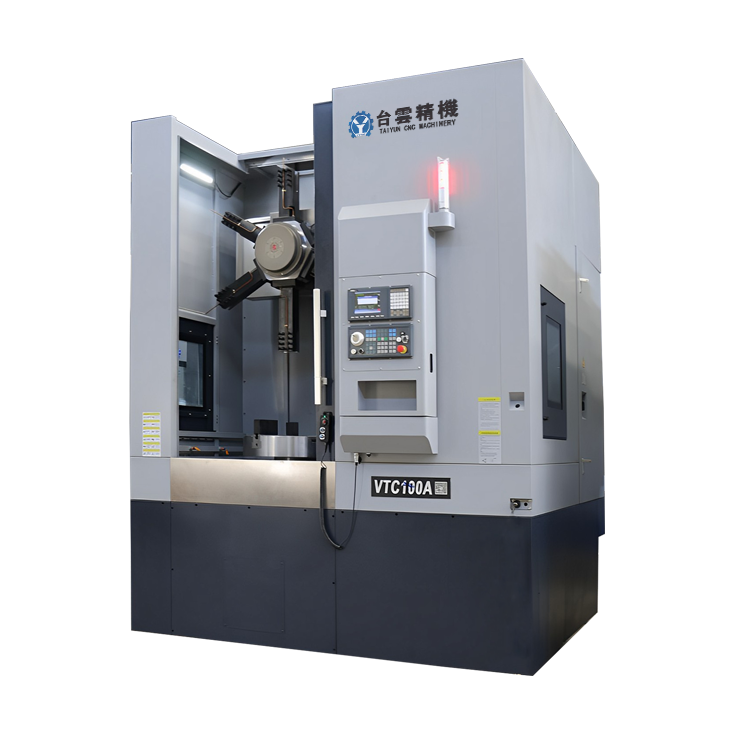

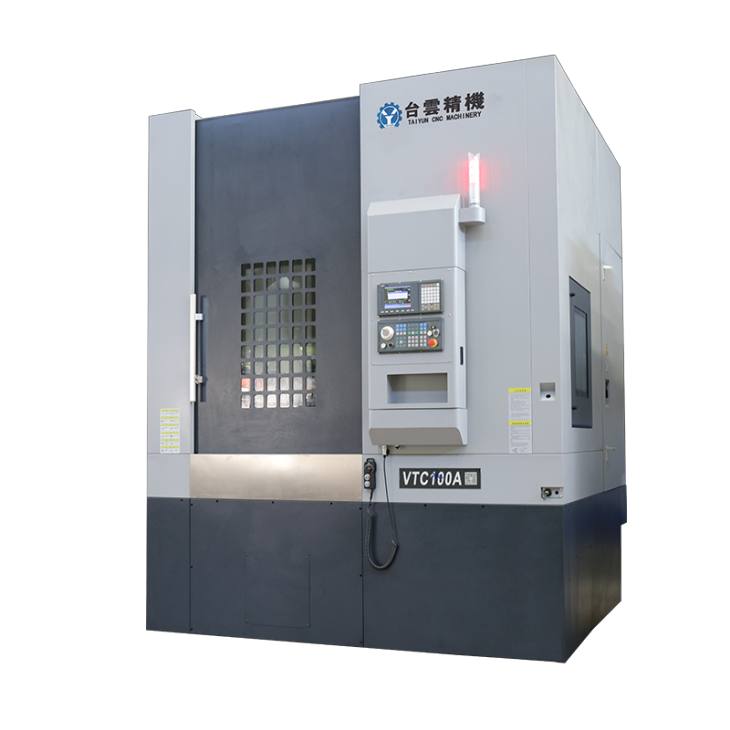

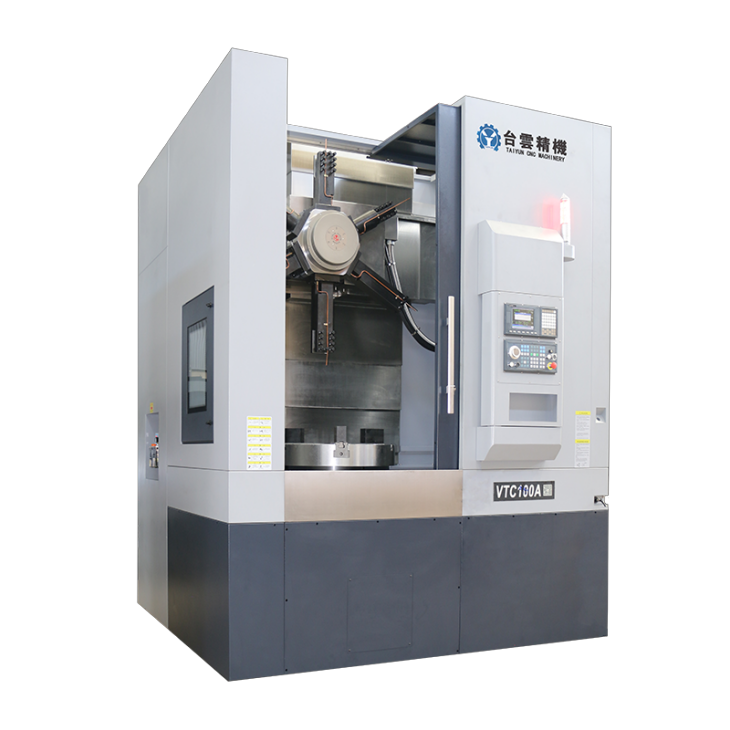

Automated vertical lathes are precise and efficient

The precision, accuracy and efficiency of automated CNC processing machine tools CNC vertical lathe, an advanced automated CNC processing machine tool, occupies an important position in the manufacturing industry with its high precision, high efficiency and high accuracy....

The precision, accuracy and efficiency of automated CNC processing machine tools CNC vertical lathe, an advanced automated CNC processing machine tool, occupies an important position in the manufacturing industry with its high precision, high efficiency and high accuracy. It not only greatly improves production efficiency, but also brings revolutionary changes to the manufacturing industry.

CNC vertical lathe, as the name suggests, is a vertical lathe that can perform various complex turning processes. Its core advantage lies in its high degree of automation and intelligence. Through computer numerical control technology, CNC vertical lathes can accurately control every processing link, from material cutting to finished products, with full automation, greatly reducing the impact of human factors on product accuracy.

In terms of accuracy, CNC vertical lathes are even more impeccable. High-precision CNC system and advanced servo control system ensure accuracy and stability during processing. Whether it is mass production or single-piece small batch production, product consistency and accuracy can be guaranteed. In terms of accuracy, the advantages of CNC vertical lathes are even more obvious. Through the preset program, no matter what complex or simple processing tasks are faced, it can be completed accurately. Moreover, through real-time monitoring and adjustment, errors in the processing process can be corrected in time to ensure that each product can meet the preset standards. As for efficiency, the advantages of CNC vertical lathes are also obvious.

Its high efficiency and continuity make it an indispensable part of the manufacturing industry. At the same time, the advanced cooling system and automatic chip removal system further improve processing efficiency and reduce equipment wear and maintenance costs.

To sum up, the CNC vertical lathe, as a highly automated, high-precision and high-efficiency CNC processing machine tool, has become the core equipment in modern manufacturing. With the continuous advancement of science and technology and the development of manufacturing industry, we have reason to believe that CNC vertical lathes will play a more important role in the future manufacturing industry.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды