- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

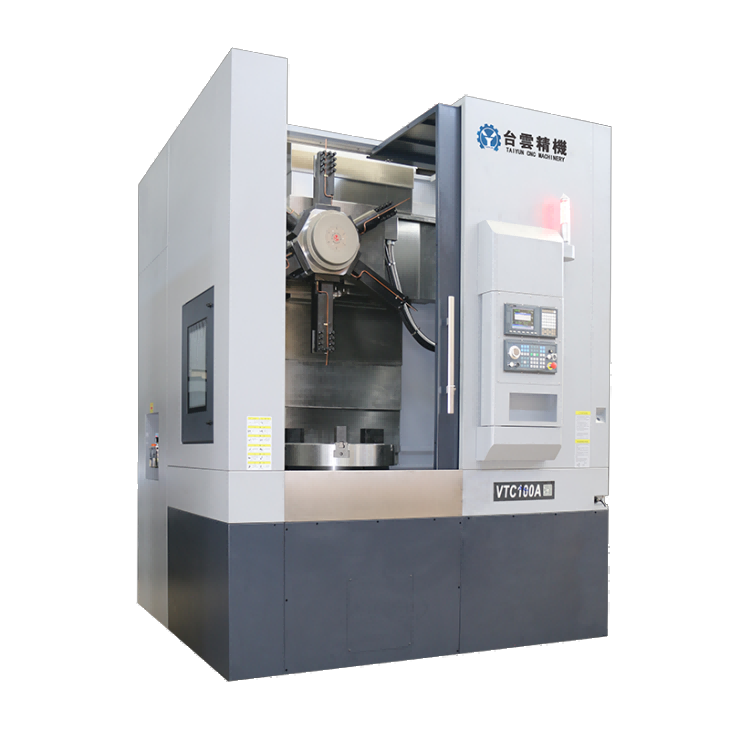

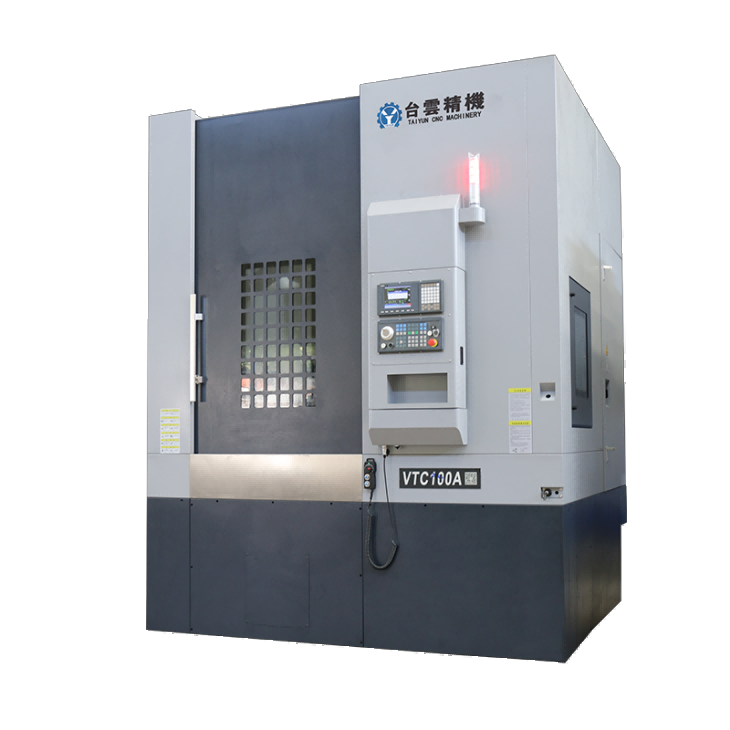

Automatic tool changing single column CNC lathe

The automatic tool changing single column CNC vertical lathe is a CNC machine tool with an automatic tool changing system and a single column structure....

The automatic tool changing single column CNC vertical lathe is a CNC machine tool with an automatic tool changing system and a single column structure. Here is some basic information and features about this machine:

1. CNC vertical lathe:

CNC vertical lathe is a CNC machine tool mainly used for turning and processing shaft parts. It has a vertical workbench and spindle, suitable for processing large-diameter parts.

2. Automatic tool changing system:

The automatic tool changing system is one of the key features of this CNC vertical lathe. It allows automatic tool changes between different processes, increasing production efficiency and reducing the need for human intervention.

3.Single column structure:

The single-column structure means that there is only one vertical column in the machine tool's support structure, making the movement of the table and spindle relatively simple. This structure helps provide stability and rigidity, making it suitable for machining large and heavy parts.

4. Processing scope:

Since CNC vertical lathes are usually used for the processing of large parts, they have a large processing range and are suitable for the production of parts with larger diameters such as wheel hubs and brake discs.

5. CNC system:

Equipped with advanced CNC systems, the automated processing process is realized through pre-programming. CNC systems allow precise control of parameters such as tool paths, feed rates, depth of cut, etc.

6. High-precision processing:

The combination of the automatic tool changing system and the CNC system enables the machine tool to achieve high-precision processing and ensure that the parts meet the design requirements.

7. Applicable industries:

This type of CNC vertical lathe is usually widely used in manufacturing, especially in the automotive, aerospace and other fields, for processing large parts.

8.Safety and ergonomic design:

Machine tools are usually designed with operator safety and comfort in mind, including appropriate safety protection facilities and human-machine interface design.

9. Maintenance and maintenance:

In order to ensure the long-term stable operation of machine tools, regular maintenance and upkeep are necessary, including cleaning, lubrication, tool replacement, etc.

The characteristic of the automatic tool-changing single-column CNC vertical lathe is its automated tool changing system, which makes it suitable for continuous processing of large parts in different processes. The application of this kind of machine tool helps to improve production efficiency and processing accuracy.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды