- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

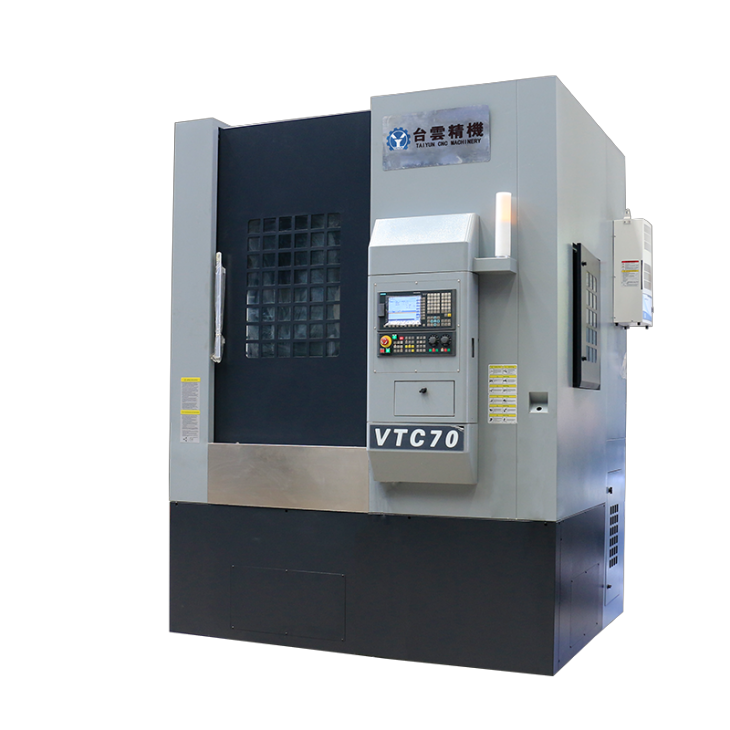

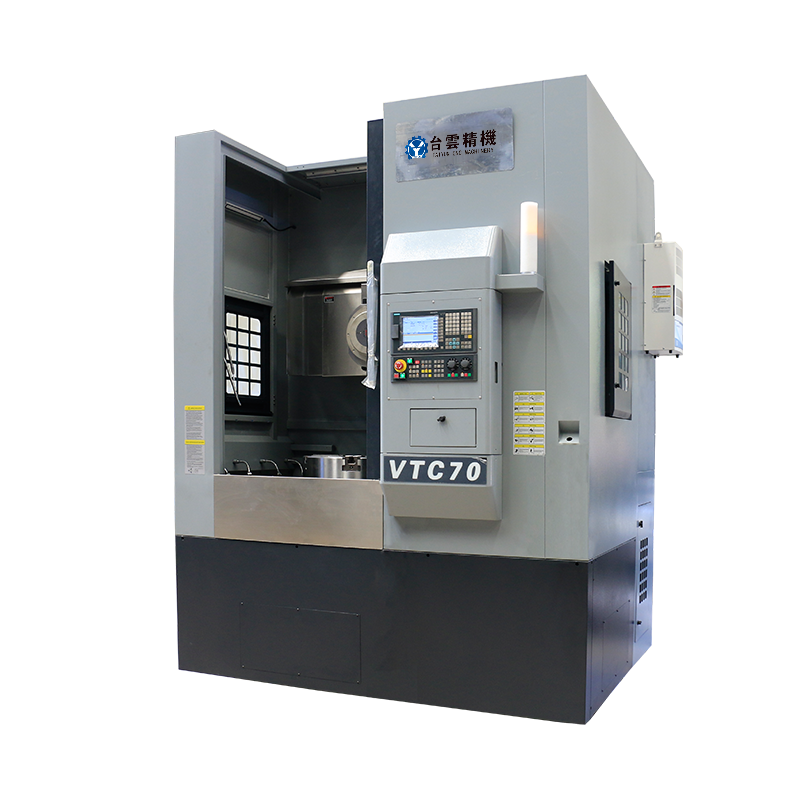

Automobile hub processing lathe

Wheel hub processing CNC lathe is a machine tool equipment specially used for processing automobile wheels....

Wheel hub processing CNC lathe is a machine tool equipment specially used for processing automobile wheels. Here are some key features and capabilities about automotive wheel machining lathes:

1. Multi-functional processing: Automobile wheel hub processing CNC lathes usually have a variety of processing functions, including turning, milling, drilling, tapping, etc., which can meet the processing needs of various parts of the wheel hub.

2. High-precision processing: In order to ensure the accuracy and surface quality of the wheel hub, automotive wheel hub processing CNC lathes usually have high-precision processing capabilities and can achieve precision processing of the wheel hub.

3. Automation functions: Automobile wheel hub processing CNC lathes are equipped with automation functions, such as automatic tool changing systems, automatic measuring devices, etc., which can improve production efficiency and reduce labor costs.

4. High-efficiency processing: CNC lathes for automotive wheel hub processing usually have high-speed processing capabilities and high-speed feed rates, which can achieve fast and efficient production and improve production efficiency.

5. Modular design: The CNC lathe for automotive wheel hub processing has a modular design, which can be flexibly combined and configured according to different processing needs, improving the flexibility and adaptability of production.

6. Tool management system: In order to ensure processing quality and improve production efficiency, automotive wheel hub processing CNC lathes are usually equipped with a tool management system, which can realize intelligent management and optimal utilization of tools.

7. High stability structure: Since the wheel hub is an important safety component of the car, CNC lathes for car wheel hub processing usually have a highly stable machine tool structure, which can ensure stability and safety during the processing.

8. Easy to operate: In order to facilitate the operators of automobile wheel hub processing CNC lathes to operate and monitor the processing process, automobile wheel hub processing lathes are usually equipped with an intuitive and easy-to-use operating interface and monitoring system, which can achieve simple and convenient operation.

To sum up, the CNC lathe for automotive wheel hub processing has the characteristics of multi-functional processing, high precision, automation functions, high efficiency, modular design, tool management system, high stability structure and easy operation. It is an important equipment for the production and processing of automotive wheel hubs. one.

| Specification | unit | VTC70 | Specification | unit | VTC70 |

| X axis | mm | 700 | Turret station | Four stations/eight stations | |

| Z axis | mm | 130-830 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ800 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ700 | cooling motor | W | 450+750 |

| turning height | mm | 700 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*1800*3200mm | |

| diameter | inch | 21″ | Gross weight (approx.) | kg | 8000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды