- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

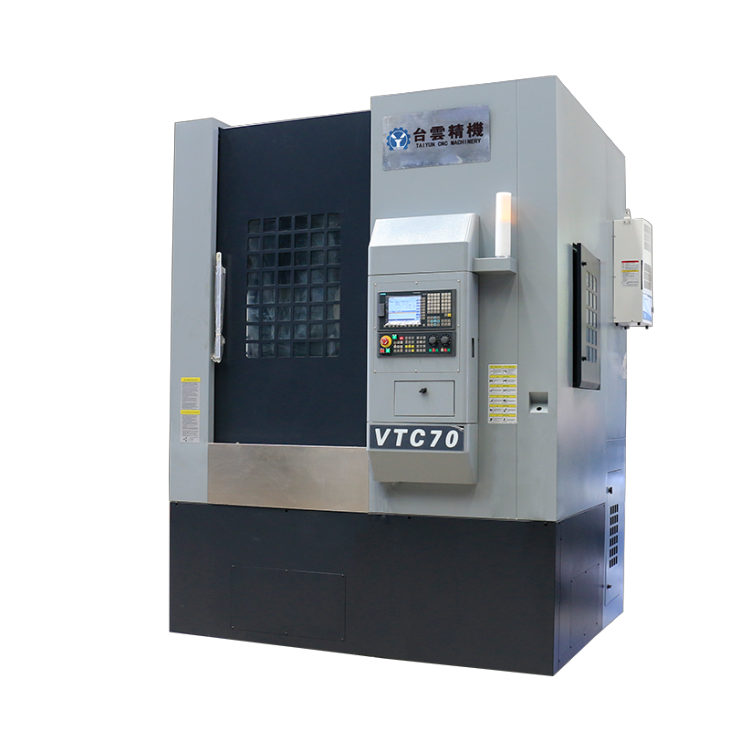

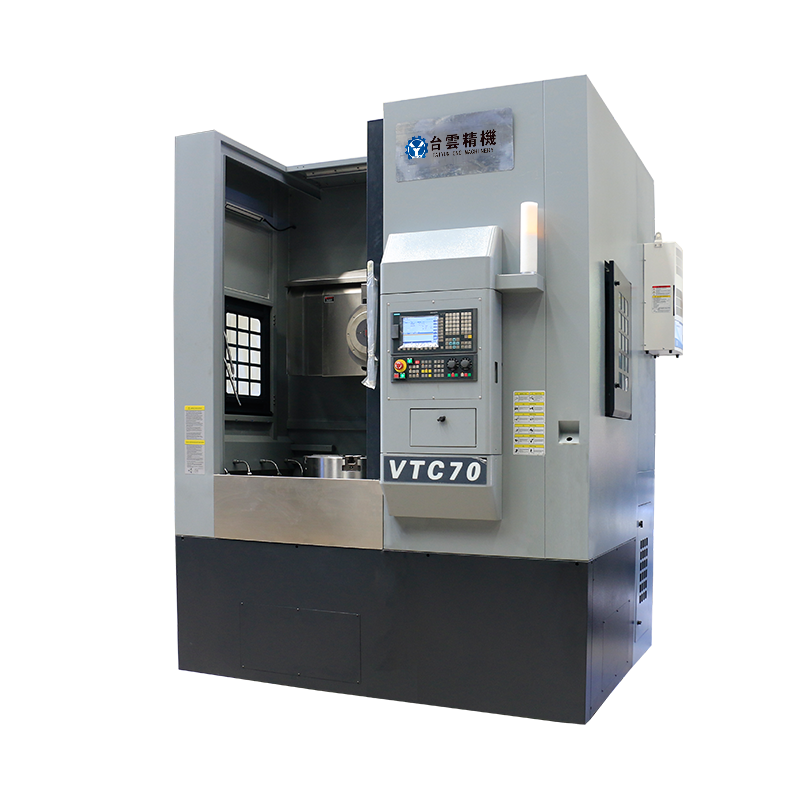

Brake drum processing machine tools

Brake drum processing machine tools are machine tools specially used to process brake drums, which are automotive parts....

Brake drum processing machine tools are machine tools specially used to process brake drums, which are automotive parts. Brake drums are an important part of the car's braking system, so their processing accuracy and quality are crucial to the car's driving safety and performance.

Brake drum processing machine tools usually have the characteristics of high precision, high rigidity and high stability to ensure that the processed brake drums can meet strict quality requirements. The cutting system and control system of brake drum processing machines are carefully designed and optimized to achieve an efficient processing process. In addition, the brake drum processing machine tool also has advanced functions such as automatic tool changing and online measurement to improve processing efficiency and reduce operating difficulty.

There are several factors to consider when choosing a brake drum machining machine. The first is the requirement for machining accuracy and surface quality, which depends on the specific specifications and use of the brake drum. Secondly, there is the demand for production efficiency, including the processing speed of machine tools, tool changing time, etc. In addition, the stability, reliability and after-sales service of the brake drum processing machine are also important factors to consider in the selection process.

For the maintenance of brake drum processing machine tools, it is necessary to regularly inspect and replace cutting tools, clean debris inside and outside the machine tool, and keep the machine tool lubricated and clean. These measures can ensure the long-term stable operation of the brake drum processing machine tool and extend its service life.

In short, brake drum processing machine tools are important equipment in the field of automobile manufacturing, and their selection, use and maintenance require careful consideration and careful operation. Through reasonable selection and maintenance, the processing quality and production efficiency of brake drums can be ensured.

| Specification | unit | VTC70 | Specification | unit | VTC70 |

| X axis | mm | 700 | Turret station | Four stations/eight stations | |

| Z axis | mm | 130-830 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ800 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ700 | cooling motor | W | 450+750 |

| turning height | mm | 700 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*1800*3200mm | |

| diameter | inch | 21″ | Gross weight (approx.) | kg | 8000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды