- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

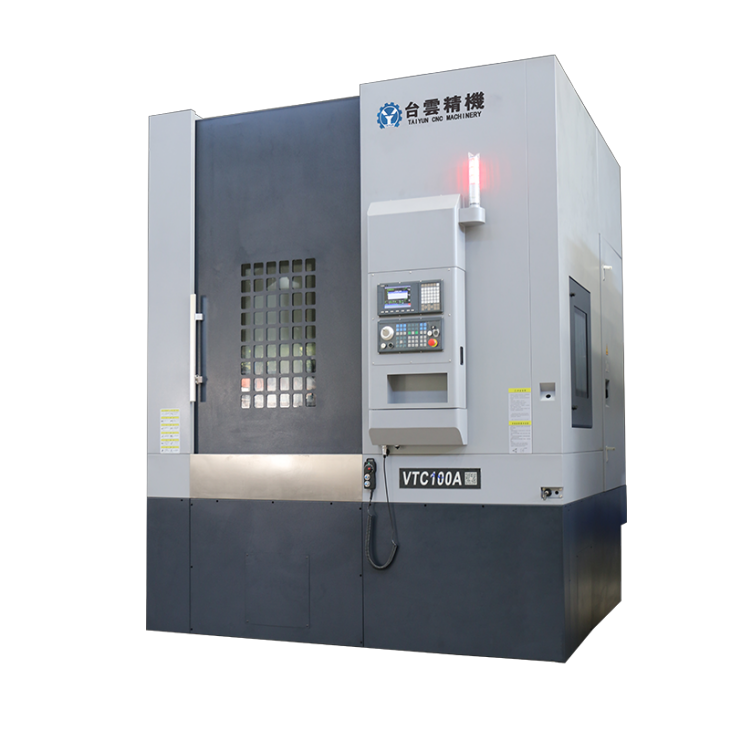

Clutch processing CNC vertical lathe

The clutch processing CNC vertical lathe is a CNC machine tool equipment specially used for processing clutches....

The clutch processing CNC vertical lathe is a CNC machine tool equipment specially used for processing clutches. As a mechanical device that connects the engine and transmission, the clutch plays an important role in the vehicle. Therefore, the processing accuracy and quality requirements for clutches are very high. As a high-precision and high-efficiency machine tool equipment, CNC vertical lathe can meet the needs of clutch processing.

When processing clutches, CNC vertical lathes can achieve high-precision cutting and processing through their precise control system and servo drive technology. Through preset programs, the machine tool can automatically complete the clutch processing process, greatly improving production efficiency and processing accuracy. At the same time, the CNC vertical lathe is also equipped with a variety of fixtures and tools to meet the processing needs of clutches of different shapes and sizes.

During the use of clutch machining CNC vertical lathe, you need to pay attention to some operating points. First of all, appropriate processing parameters should be selected, such as spindle speed, feed speed, etc., to ensure the stability and accuracy of the processing process. Secondly, the tool motion trajectory needs to be reasonably set according to the specific size and shape of the clutch to ensure that the processed clutch meets the design requirements. In addition, you also need to pay attention to the safe operating procedures of machine tools to avoid personal injury and equipment failure caused by operating errors.

In addition to the operating points, the maintenance and upkeep of the clutch machining CNC vertical lathe is also very important. Regular cleaning, lubrication and inspection of machine tools can ensure the normal operation and extend the service life of CNC vertical lathes. At the same time, the control system and servo drive system of the CNC vertical lathe need to be regularly inspected and debugged to ensure their stability and accuracy.

In short, the CNC vertical lathe for clutch processing is an efficient and precise machine tool equipment that can meet the needs of clutch processing. During use, you need to pay attention to operating points and maintenance to ensure processing quality and normal operation of the machine tool.

| Specification | unit | VTC100A | Specification | unit | VTC100A |

| X axis | mm | 850 | Turret station | Four stations | |

| Z axis | mm | 850 | X-axis rolling linear guide | 2 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ1250 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ1200 | cooling motor | W | 750+1200 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 50-800 | Repeatability | mm | ±0.008 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.01 |

| Spindle diameter | mm | Φ200 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2950*2800*3850mm | |

| diameter | inch | Φ1000 | Gross weight (approx.) | KG | 11500 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды