- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

cnc lathe machine price

...

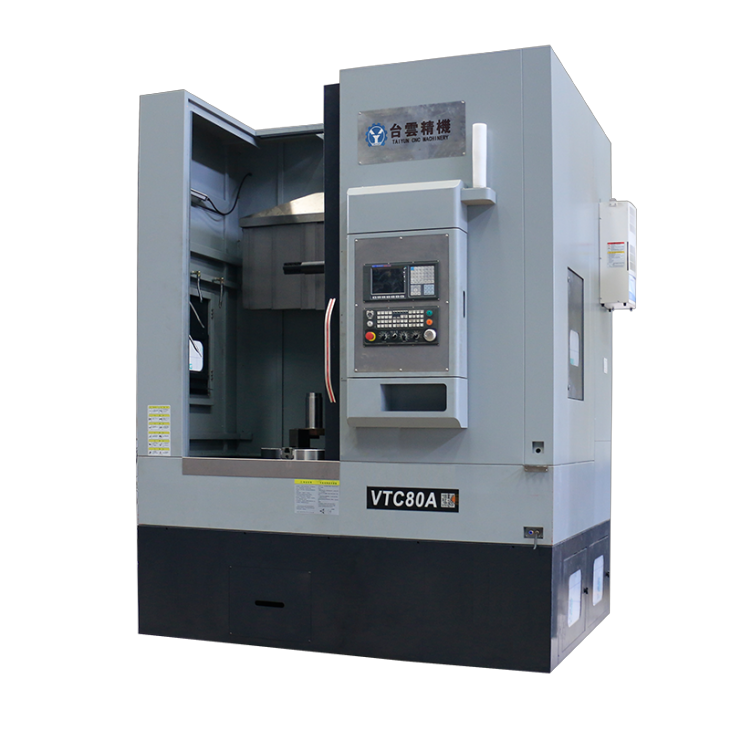

CNC vertical lathes usually have ultra-high rigidity and ultra-heavy load capacity, which allows it to withstand high loads and maintain machining accuracy. These lathes are usually used to process workpieces with various complex shapes, including internal and external cylindrical surfaces, conical surfaces, end faces, grooving and chamfering, etc. The following are some features and functions of CNC vertical lathes:

1. Ultra-high rigidity: CNC vertical lathes usually adopt heavy-duty cast iron bodies or steel structures, which have extremely high rigidity and stability and can maintain machining accuracy during high-speed machining.

2. Overweight load capacity: CNC vertical lathes are designed with powerful spindle and workbench structures that can withstand overweight loads and are suitable for processing large and heavy workpieces.

3. Multifunctional processing: CNC vertical lathes have a variety of processing functions, including turning, boring, milling, drilling, tapping, etc., which can meet the processing needs of various complex workpieces.

4. Internal and external cylindrical surface processing: CNC vertical lathe can accurately process the internal and external cylindrical surfaces of the workpiece, which has high roundness and surface roughness requirements.

5. Taper processing: CNC vertical lathe can realize taper processing of workpieces, including inner and outer cones, which can meet the engineers' requirements for the shape of the workpiece.

6. End face processing: The CNC vertical lathe has the end face processing function, which can accurately process the end face of the workpiece to ensure the flatness and verticality of the end face.

7. Grooving and chamfering: The CNC vertical lathe can also perform grooving and chamfering on the workpiece, improving the assembly accuracy and appearance quality of the workpiece.

8. Automated processing: CNC vertical lathes are equipped with CNC control systems, which can realize automated processing operations through pre-programmed processing programs, improving production efficiency and processing accuracy.

In general, CNC vertical lathes have strong processing capabilities and flexibility and can meet the needs of complex workpiece processing. They are one of the common high-precision processing equipment in the manufacturing industry.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды