- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Wheel hub forming CNC vertical lathe

CNC vertical lathe is an efficient and high-precision wheel hub forming equipment, which is widely used in automobile manufacturing, mechanical processing and other fields....

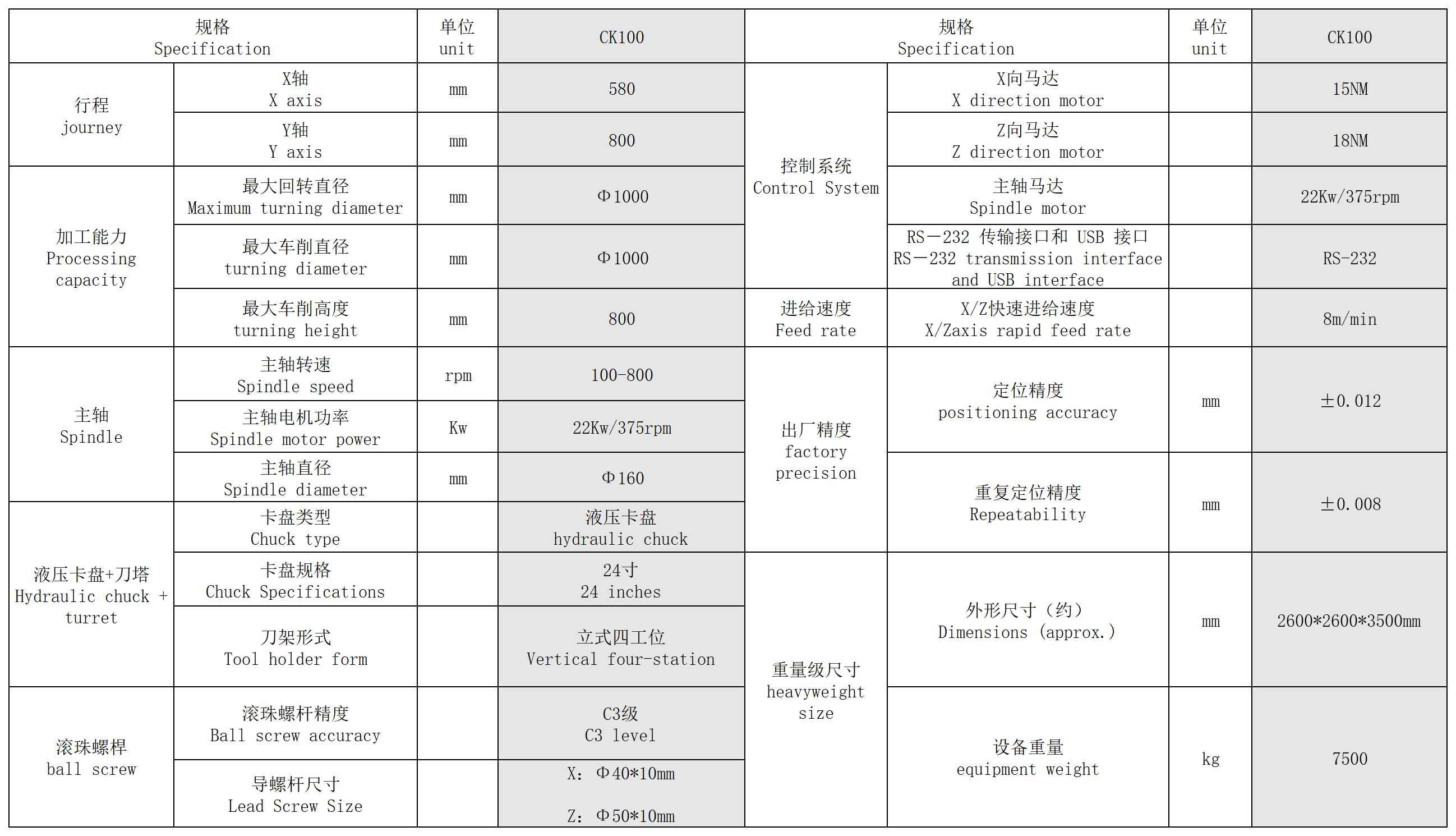

CNC vertical lathe is an efficient and high-precision wheel hub forming equipment, which is widely used in automobile manufacturing, mechanical processing and other fields. The equipment adopts advanced CNC technology to realize automated and intelligent production, improve production efficiency and reduce production costs.

As a type of CNC vertical lathe, the CNC vertical lathe for automobile wheel hub molding is specially designed for automobile wheel hub processing. The equipment uses high-strength materials to ensure processing accuracy and stability, and can process automobile wheels of various specifications and shapes. At the same time, the equipment is also equipped with a variety of auxiliary devices, such as fixtures, cutting tools, cooling systems, etc., to ensure the stability and safety of the processing process.

1. High-precision processing: Using advanced CNC technology, high-precision and high-efficiency processing can be achieved, improving product quality and consistency.

2. High degree of automation: It can realize automated and intelligent production, reduce manual intervention and labor intensity, and improve production efficiency.

3. Wide processing range: It can process automobile wheels of various specifications and shapes to meet the needs of different customers.

4. Good stability: Use high-strength materials and a variety of auxiliary devices to ensure the stability and safety of the processing process.

5. Easy to maintain: The equipment has a simple structure and is easy to operate, making it convenient for daily maintenance and upkeep.

This equipment is suitable for automobile manufacturing, mechanical processing and other fields, and is mainly used for the processing and manufacturing of automobile wheels. By using this equipment, companies can improve production efficiency, reduce costs, and enhance market competitiveness.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды