- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

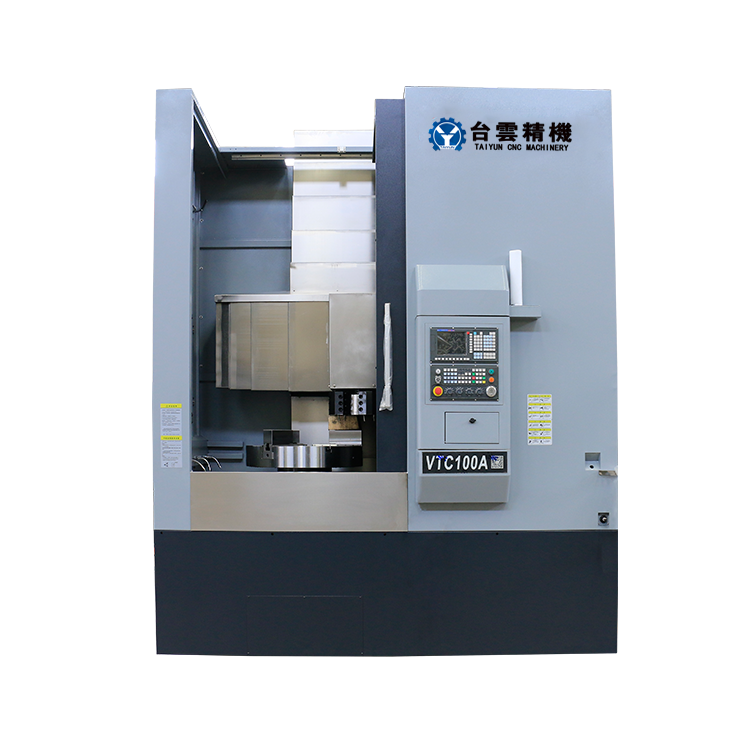

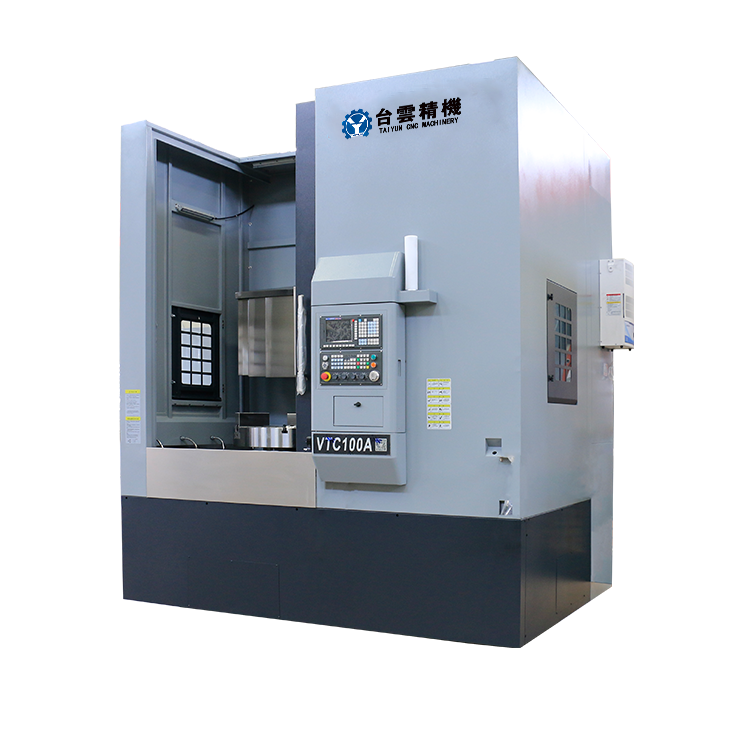

CNC vertical lathe for processing shell parts

CNC vertical lathe for processing shell parts is an important technology in the field of mechanical processing. It uses the high precision and efficiency of CNC vertical lathe to achieve precision processing of shell parts....

CNC vertical lathe for processing shell parts is an important technology in the field of mechanical processing. It uses the high precision and efficiency of CNC vertical lathe to achieve precision processing of shell parts. The following will introduce in detail several key aspects of CNC vertical lathe processing of shell parts:

1. Characteristics and advantages of CNC vertical lathe

CNC vertical lathes have the characteristics of high precision, high rigidity, and high efficiency, and are suitable for processing various complex-shaped shell parts. It adopts a computer control system, which can realize automated and intelligent processing processes, greatly improving processing accuracy and efficiency. In addition, CNC vertical lathes also have good stability and reliability, ensuring long-term and stable processing quality.

2. Processing requirements for shell parts

Shell parts usually have complex shapes and structures and require high-precision processing to ensure their performance and quality. At the same time, since most shell parts are made of metal or alloy, factors such as the hardness and toughness of the material need to be taken into consideration during the processing to ensure the smooth progress of the processing.

3. Application of CNC vertical lathe in the processing of shell parts

Programming and process planning: Carry out CNC programming and process planning according to the shape and size of shell parts. Through reasonable process planning and programming, precise processing of shell parts can be achieved.

Fixtures and positioning: Design appropriate fixtures and positioning devices for CNC vertical lathes for processing shell parts to ensure the stability and accuracy of shell parts during processing. The fixture should be rigid and precise enough to withstand the cutting forces and vibrations during machining.

Cutting parameter selection: CNC vertical lathe for processing shell parts, select appropriate cutting parameters, such as cutting speed, feed amount, etc., according to the properties of the material and processing requirements. Reasonable cutting parameters can improve processing efficiency and quality while reducing tool wear and energy consumption.

Processing process monitoring: During the processing of shell parts, the CNC vertical lathe monitors the processing status in real time to ensure the stability and safety of the processing process. By monitoring parameters such as cutting force and temperature, abnormal conditions can be discovered and dealt with in a timely manner to ensure processing quality.

4. Precautions and maintenance

Perform regular maintenance on the CNC vertical lathe to ensure it is in good working condition. Check the operation of key components such as electrical systems, hydraulic systems, and transmission systems, and replace worn parts in a timely manner.

Keep the processing area clean and tidy to avoid dust and debris from affecting the processing process. Regularly clean the dust and oil inside and outside the machine tool to keep the machine tool clean.

Provide training and guidance to operators to ensure that they are familiar with the operating procedures and maintenance methods of CNC vertical lathes. Improve the skill level and safety awareness of operators and reduce the probability of operating errors and accidents.

To sum up, CNC vertical lathe for processing shell parts is a high-precision and high-efficiency processing technology. Through reasonable process planning, programming and operation and maintenance, precise processing and high-quality production of shell parts can be achieved. .

| Specification | unit | VTC100A | Specification | unit | VTC100A |

| X axis | mm | 850 | Turret station | Four stations | |

| Z axis | mm | 850 | X-axis rolling linear guide | 2 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ1250 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ1200 | cooling motor | W | 750+1200 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 50-800 | Repeatability | mm | ±0.008 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.01 |

| Spindle diameter | mm | Φ200 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2950*2800*3850mm | |

| diameter | inch | Φ1000 | Gross weight (approx.) | KG | 11500 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды