- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

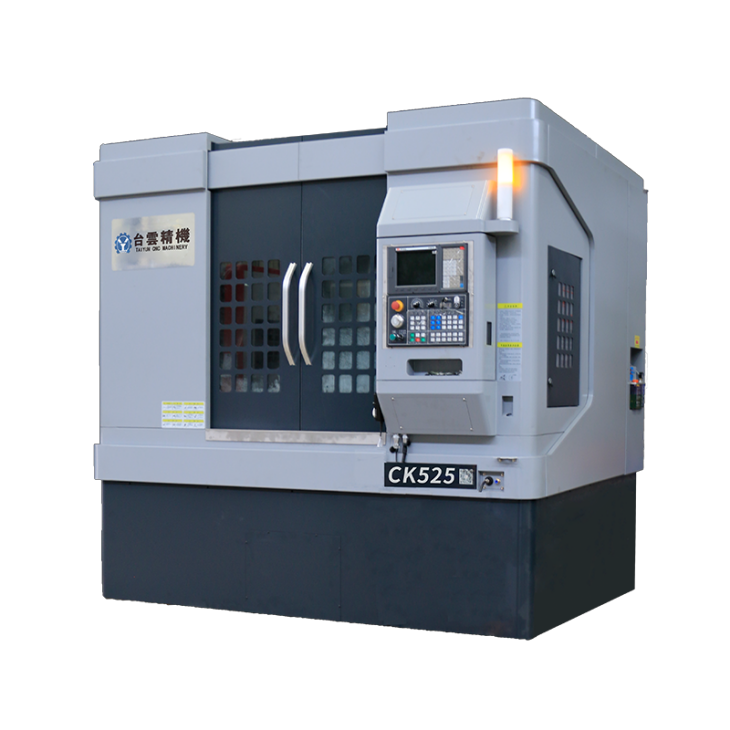

CNC vertical lathe hardware parts processing

Revolutionary Tools for Hardware Parts Processing In today's manufacturing industry, CNC vertical lathes have become the core equipment in the field of hardware parts processing....

Revolutionary Tools for Hardware Parts Processing In today's manufacturing industry, CNC vertical lathes have become the core equipment in the field of hardware parts processing. It integrates high precision, high efficiency and high automation, providing manufacturers with a new production method and greatly improving production efficiency and product quality.

CNC vertical lathes can process a variety of complex hardware parts, whether small or large, simple or complex, it can handle them easily. Its high-precision spindle and advanced CNC system ensure that the processed parts have extremely high precision and consistency and meet various strict quality standards. In addition, CNC vertical lathes have a high degree of automation, which can significantly reduce manual intervention and reduce production costs. At the same time, its powerful processing capabilities also mean that multiple steps, such as milling, drilling, tapping, etc., can be completed in a single operation, greatly improving production efficiency.

What's more worth mentioning is that the operation of CNC vertical lathe is simple and easy to understand, and workers can operate it skillfully with only a small amount of professional training. This not only reduces the skill requirements for operators, but also enables companies to quickly adapt when equipment is updated, further enhancing the company's competitiveness. Today, with increasing awareness of environmental protection, the high efficiency and low energy consumption of CNC vertical lathes have also become an important factor in their popularity. Compared with traditional processing methods, it can significantly reduce material waste and energy consumption, saving costs for enterprises while also contributing to environmental protection.

In general, CNC vertical lathes, as a revolutionary tool for hardware parts processing, have and will continue to play an important role in the manufacturing industry. It provides enterprises with an effective way to improve production efficiency, improve product quality, and reduce production costs. It is an indispensable and important equipment for modern manufacturing.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды