- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

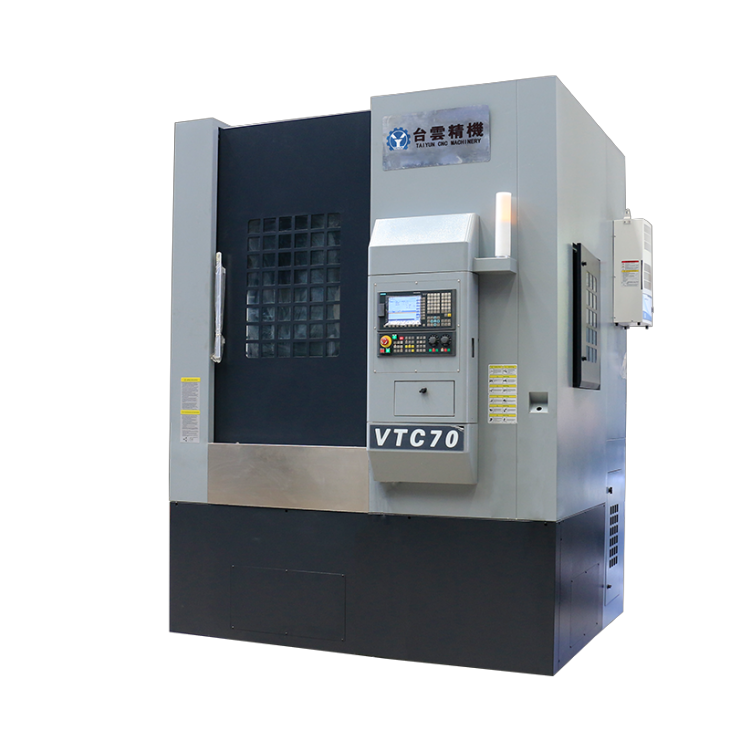

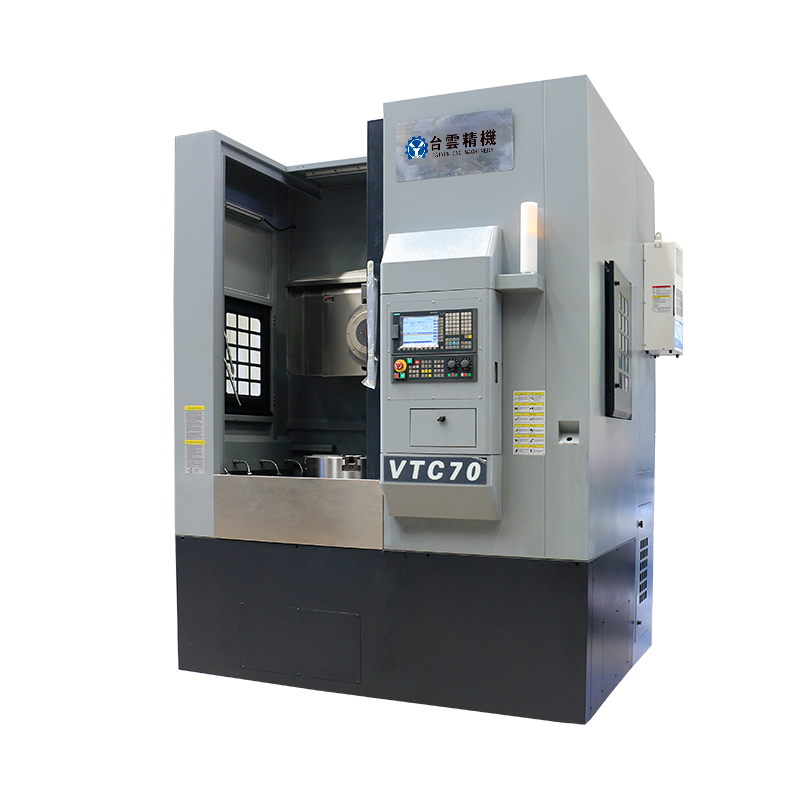

CNC vertical lathe processing equipment general machine

CNC vertical lathes have a wide range of applications in general processing equipment and can be used to process various types of mechanical equipment parts....

CNC vertical lathes have a wide range of applications in general processing equipment and can be used to process various types of mechanical equipment parts. The following are the general steps and precautions for CNC vertical lathe processing equipment:

1. Material selection: CNC vertical lathes select suitable metal materials, such as aluminum alloys, steel, etc., according to the specific requirements of the general equipment and the functions of the parts.

2. Design processing technology: CNC vertical lathes design processing process routes according to the shape, size and processing requirements of parts, including determining the processing sequence, tool selection, cutting parameters, etc.

3. Clamping scheme design: CNC vertical lathes design suitable clamping schemes to ensure that parts are firmly clamped during processing to avoid deformation and errors.

4. Tool selection: CNC vertical lathes select suitable tool types and specifications, such as turning tools, milling cutters, drill bits, etc., according to the shape and processing requirements of parts.

5. Processing parameter setting: CNC vertical lathes set suitable processing parameters such as cutting speed, feed speed, cutting depth, etc. according to factors such as material hardness and cutting performance.

6. Process monitoring: During the processing, the CNC vertical lathe monitors the processing status and processing quality, adjusts the processing parameters and tools in time, ensures the processing process is stable and efficient, and ensures the dimensional accuracy and surface quality of the processed parts.

7. Post-processing: The CNC vertical lathe performs necessary post-processing on the processed parts, such as deburring, polishing, heat treatment, etc., to improve the surface quality and functionality of the parts.

8. Quality inspection: The CNC vertical lathe performs quality inspection on the processed parts to ensure that they meet the design requirements and standards.

The CNC vertical lathe is flexible and efficient in terms of the generality of processing equipment. It can be applied to the processing of parts of various shapes and sizes, providing a reliable processing solution for mechanical equipment manufacturing.

| Specification | unit | VTC70 | Specification | unit | VTC70 |

| X axis | mm | 700 | Turret station | Four stations/eight stations | |

| Z axis | mm | 130-830 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ800 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ700 | cooling motor | W | 450+750 |

| turning height | mm | 700 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*1800*3200mm | |

| diameter | inch | 21″ | Gross weight (approx.) | kg | 8000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды