- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

CNC vertical machining machine tools

A CNC vertical machining machine is a common type of CNC machine tool that is typically used to perform vertical machining operations....

A CNC vertical machining machine is a common type of CNC machine tool that is typically used to perform vertical machining operations. Here is some basic information and features about CNC vertical machining machines:

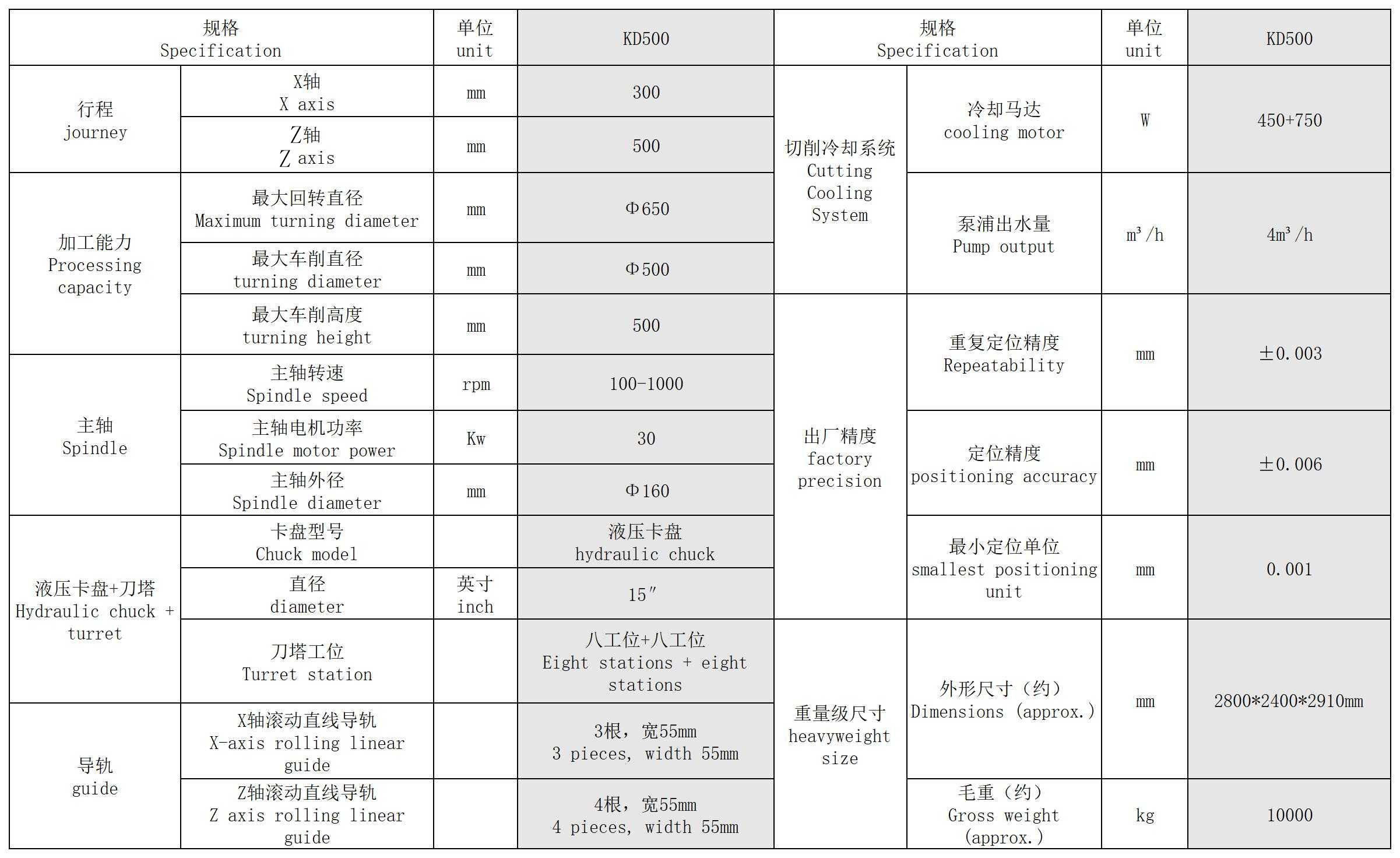

1. Vertical structure: The workbench and spindle of CNC vertical processing machine tools are arranged vertically. The workpiece is fixed on the workbench, and the tool enters the processing from above the spindle. This structure makes the processing process more stable and is suitable for flat processing or hole processing on the workpiece surface.

2. CNC control system: CNC vertical processing machine tools are equipped with a CNC control system that can realize automated processing operations through pre-programmed processing programs. Operators can input processing parameters, processing paths and other information through the control system to achieve precise processing of the workpiece.

3. Multi-function processing: CNC vertical processing machine tools can perform a variety of processing operations, including turning, drilling, tapping, etc., and are suitable for workpiece processing needs of different shapes and sizes.

4. High-precision processing: CNC vertical processing machine tools have high processing accuracy and can achieve precise control of the size, shape and surface quality of workpieces, and are suitable for processing workpieces that require higher precision.

5. Wide scope of application: CNC vertical processing machine tools are suitable for processing workpieces of various materials and can meet the processing needs of different industries, such as automobile manufacturing, aerospace, mold manufacturing, etc. It is especially suitable for roughing and finishing machining of automobile hubs, flywheel housings, clutch housings, pressure plates, differential housings, discs and other parts.

6. High-efficiency production: CNC vertical processing machine tools have the characteristics of high-speed processing and high-efficiency production, which can realize rapid processing of workpieces and improve production efficiency and processing quality.

7. Strong flexibility: CNC vertical processing machine tools have strong processing flexibility and can be flexibly adjusted and customized according to different processing requirements and workpiece characteristics. They are suitable for mass production and personalized custom processing.

In general, CNC vertical processing machine tools play an important role in the manufacturing industry. They have the advantages of high precision, high efficiency, and multi-function. They can meet the needs of complex workpiece processing and improve production efficiency and product quality.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды