- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

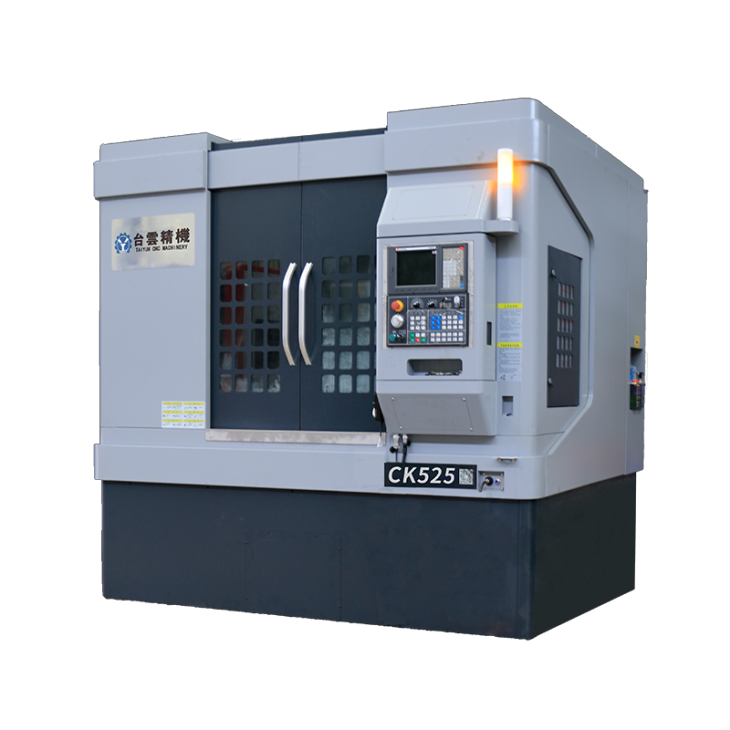

CNC vertical turning center

CNC turning center is an advanced machine tool equipment that combines CNC technology and turning technology to provide efficient and precise processing solutions for modern manufacturing....

CNC turning center is an advanced machine tool equipment that combines CNC technology and turning technology to provide efficient and precise processing solutions for modern manufacturing. The following is a detailed introduction to CNC turning centers:

1. Characteristics of CNC turning center

High precision: CNC turning center adopts advanced CNC system, which can achieve micron-level processing accuracy and meet the processing needs of high-precision parts.

High efficiency: Through optimized programming and automated control, CNC turning centers can greatly improve processing efficiency and reduce production cycles.

Flexibility: CNC turning centers have a wide range of processing capabilities and can adapt to the processing needs of parts of different materials, different shapes and different sizes.

Stability: The CNC turning center adopts a solid bed structure and advanced drive system to ensure long-term stable operation and improve processing quality and equipment service life.

2. Application areas of CNC turning centers

CNC turning centers are widely used in aviation, aerospace, automobiles, machinery, electronics and other fields. They are especially suitable for processing parts with complex shapes and high precision requirements, such as shaft parts, disc parts, gears, etc.

3. Processing capabilities of CNC turning centers

Turning processing: CNC turning center can perform turning processing of internal and external cylindrical surfaces, conical surfaces, spherical surfaces, threads, etc. to achieve the basic shape processing of parts.

Milling processing: Some CNC turning centers also have milling functions, which can perform milling processing on flat surfaces, curved surfaces, etc., expanding the processing range.

Drilling: CNC turning centers can drill holes through drills to meet the hole processing requirements on parts.

4. Operation and maintenance of CNC turning center

Operation: Operating a CNC turning center requires certain professional skills and experience. Operators need to be familiar with CNC programming, machine tool operation and maintenance, etc.

Maintenance: Regularly maintain the CNC turning center, including cleaning the machine tool, checking the electrical system, lubrication system, etc., to ensure that the equipment is in good condition and extend its service life.

In short, CNC turning center is an efficient and precise processing equipment that provides strong support for the development of modern manufacturing industry. With the continuous advancement of technology and the continuous expansion of application fields, CNC turning centers will play a more important role in the future.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды