- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

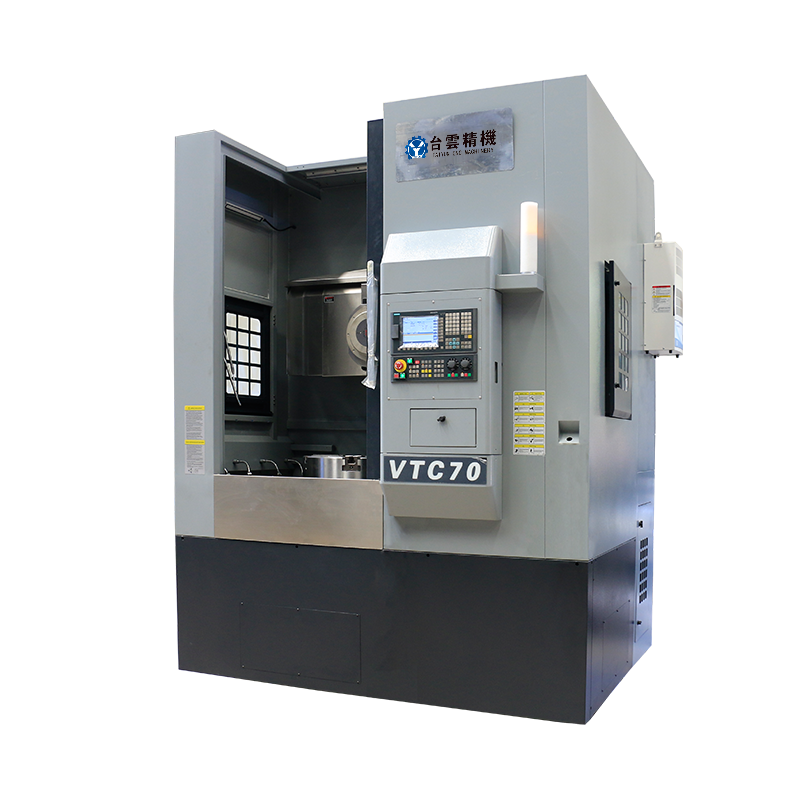

Cutting CNC vertical lathe is easy to maintain

The cutting CNC vertical lathe is a high-precision, high-efficiency metal cutting machine tool that is widely used in machinery manufacturing, automobiles, aerospace, energy and other fields....

The cutting CNC vertical lathe is a high-precision, high-efficiency metal cutting machine tool that is widely used in machinery manufacturing, automobiles, aerospace, energy and other fields. The cutting CNC vertical lathe is controlled by CNC technology and has the characteristics of automation, high precision, high rigidity, and high stability, and can achieve precision machining of various complex workpieces.

The main features of cutting CNC vertical lathes include:

1. High-precision processing: CNC vertical lathes use advanced CNC systems and servo control technology to achieve high-precision and high-efficiency cutting processing. The cutting CNC vertical lathe can ensure the dimensional accuracy, shape accuracy and surface quality of the workpiece to meet the needs of high-precision machining.

2. High degree of automation: The cutting CNC vertical lathe has functions such as automatic feeding, automatic tool changing, and automatic tool setting, which can greatly reduce manual intervention and improve production efficiency. At the same time, the cutting CNC vertical lathe also has automatic detection and automatic compensation functions, which can automatically adjust cutting parameters to ensure the stability and accuracy of the cutting CNC vertical lathe processing process.

3. Good rigidity and stability: The cutting CNC vertical lathe adopts a highly rigid structural design. Key components such as the bed, column, and spindle are carefully designed and manufactured. The cutting CNC vertical lathe has high rigidity and stability. This can ensure the stability and accuracy of CNC vertical lathes under high-speed, heavy-load cutting conditions.

4. Wide range of processing: CNC vertical lathes are suitable for processing workpieces of various shapes and sizes, including discs, shafts, sleeves, etc. At the same time, the cutting CNC vertical lathe can also perform multi-axis linkage processing to achieve complex three-dimensional surface processing.

5. Easy maintenance: The cutting CNC vertical lathe adopts a modular design, and key components are easy to disassemble and replace. At the same time, the cutting CNC vertical lathe is also equipped with an advanced fault diagnosis system, which can monitor the operating status of the equipment in real time and detect and solve problems in a timely manner. These features make the maintenance of cutting CNC vertical lathe relatively simple and reduce maintenance costs.

In short, the cutting CNC vertical lathe is a metal cutting machine tool with high precision, high efficiency, high rigidity and high stability, and has a wide range of application prospects. The cutting CNC vertical lathe can meet the processing needs of various complex workpieces and improve production efficiency and product quality. It is one of the indispensable and important equipment in the field of modern machinery manufacturing.

| Specification | unit | VTC70 | Specification | unit | VTC70 |

| X axis | mm | 700 | Turret station | Four stations/eight stations | |

| Z axis | mm | 130-830 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ800 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ700 | cooling motor | W | 450+750 |

| turning height | mm | 700 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*1800*3200mm | |

| diameter | inch | 21″ | Gross weight (approx.) | kg | 8000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды