- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

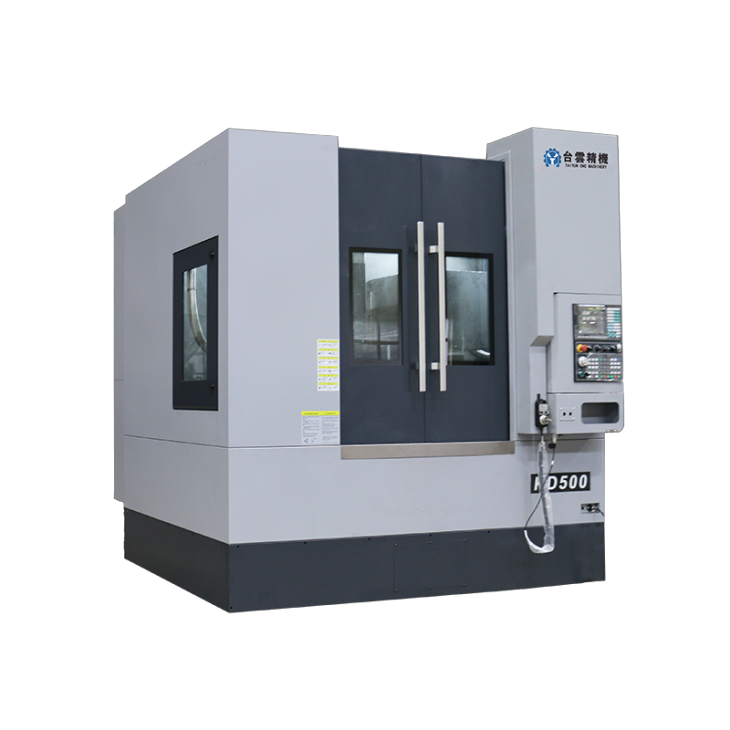

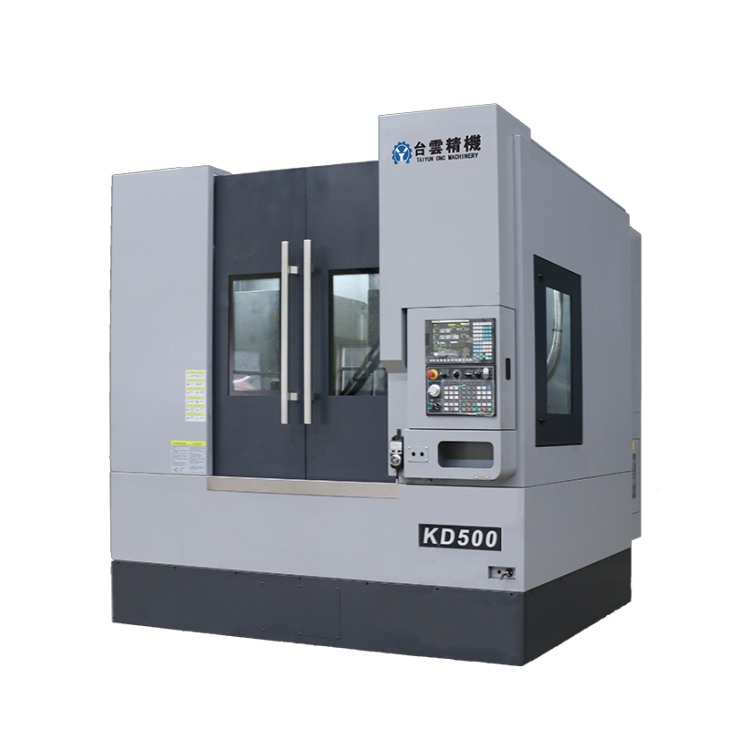

Double-column double-tool holder CNC vertical lathe

The double-column double-tool turret CNC vertical lathe is a CNC vertical lathe, which is characterized by a double-column structure and a double-tool turret design....

The double-column double-tool turret CNC vertical lathe is a CNC vertical lathe, which is characterized by a double-column structure and a double-tool turret design. The following are some features of this CNC vertical lathe:

1. Double-column structure: The double-column structure means that the lathe has two vertical pillars that support the spindle and beam. This structure helps provide greater support and stability, especially when processing large, heavy workpieces.

2. Double tool rest design: Double tool rest means that there are two tool rests on the lathe, and each tool rest is equipped with tools. This design allows two tools to be processed at the same time, improving production efficiency.

3. CNC system: Equipped with a computer numerical control (CNC) system to achieve precise control of parameters such as tool motion trajectory and processing depth through CNC programming.

4. Automatic tool changing system: It has automatic tool changing function, which can automatically change different types or sizes of tools during the processing process, improving the flexibility of processing.

5. Automatic clamping system: Equipped with an automatic clamping system that can automatically clamp and release workpieces, reducing the need for manual operations and improving production efficiency.

6. High-speed drive system: Equipped with a high-speed drive system to achieve fast and accurate tool movement, improving processing speed and overall production efficiency.

7. Flexible production: Able to adapt to different types, sizes and shapes of workpieces to achieve flexible production, suitable for small batches and diversified production.

8. Data collection and analysis: Collect and analyze data during processing in real time to optimize the production process, improve equipment utilization, and perform predictive maintenance.

This double-column, double-tool-post CNC vertical lathe is designed to combine stability and high efficiency, and is suitable for application scenarios that require high machining accuracy and production efficiency.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды