- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Factory direct sales CNC lathe

A CNC vertical lathe is a CNC lathe that features a vertical tool holder and worktable....

A CNC vertical lathe is a CNC lathe that features a vertical tool holder and worktable. It is usually designed for vertical cutting operations.

Here are some key features and applications for CNC vertical lathes, high-speed and cutting lathes:

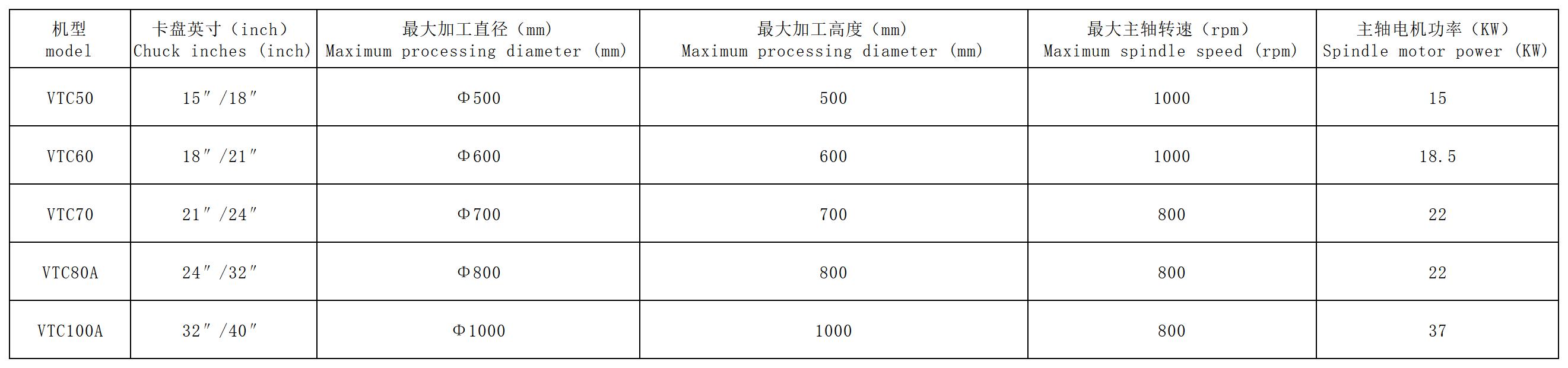

1. CNC vertical lathe: This is a CNC lathe whose spindle is perpendicular to the workbench. This design makes machining easier, especially for workpieces that require vertical cutting. The CNC system allows precise control of tool paths and cutting parameters, improving the accuracy and efficiency of machining.

2. High speed: High speed usually means that the spindle can rotate at a relatively high speed. High RPM is critical for certain materials and cutting operations because it improves cutting efficiency, surface quality, and facilitates machining with thin, straight tools.

3. Cutting lathe: A cutting lathe is a machine tool specially used for cutting and processing metal materials. It uses cutting tools to cut out the shape of the workpiece to obtain the required size and shape. Cutting lathes can perform a variety of cutting operations, including turning, boring, milling, and more.

4. Application fields: CNC vertical lathes, high-speed and cutting lathes are usually used in metal processing fields that require high precision and high efficiency. For example, in the fields of mold manufacturing, aerospace, automobile industry, etc., this equipment can be used to process various complex-shaped workpieces.

5. Tool selection: Due to the characteristics of high rotation speed, choosing the right tool is crucial to the performance of CNC vertical lathe. Carbide and coated tools are generally better suited to the demands of high-speed cutting.

When selecting a CNC vertical lathe, high-speed, cutting lathe, you need to consider the material to be processed, the machining requirements, and the required accuracy and surface quality. This type of machine tool plays an important role in modern manufacturing, providing reliable solutions for efficient and precise metal processing.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды