- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

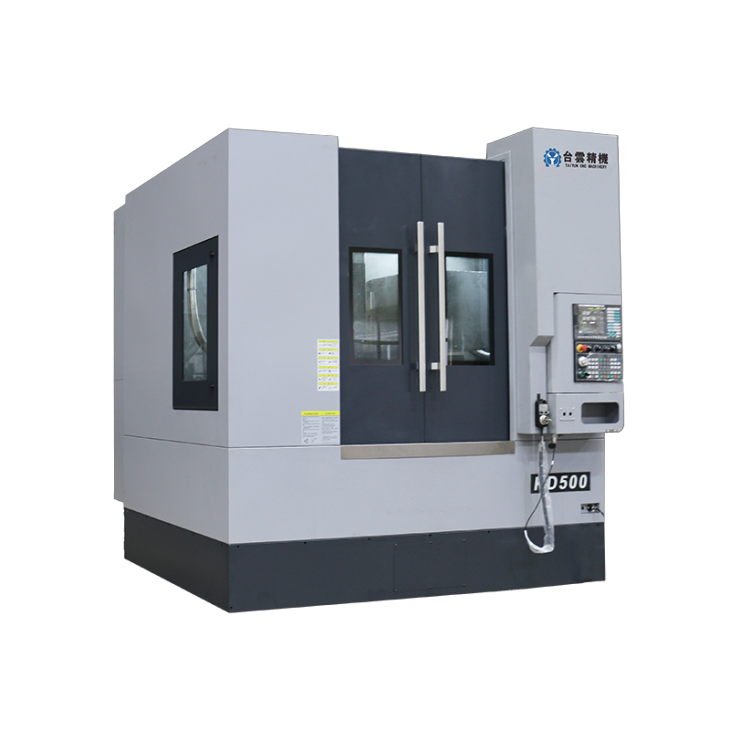

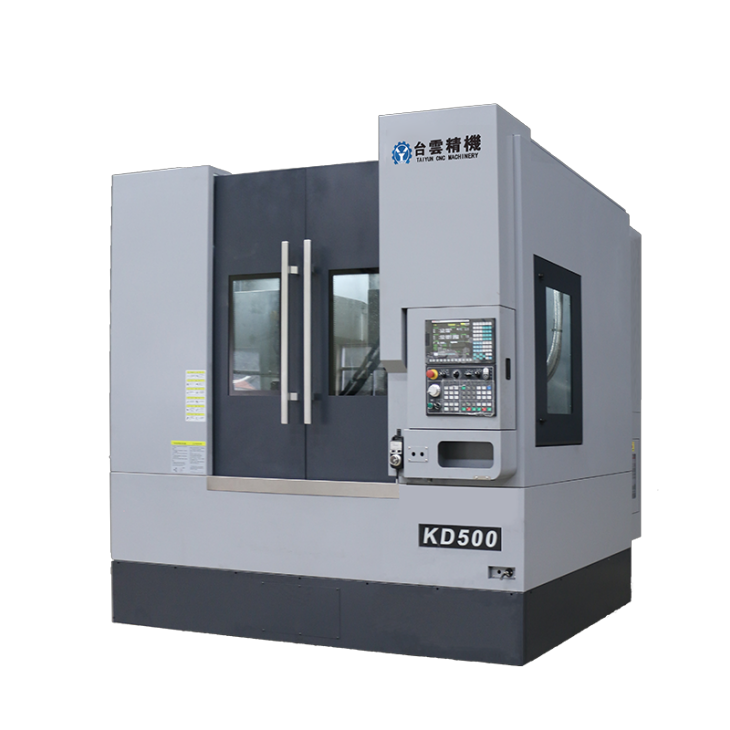

Flywheel housing processing CNC vertical lathe

In modern automobile manufacturing, flywheel housing processing is a crucial link....

In modern automobile manufacturing, flywheel housing processing is a crucial link. As a key component in the engine, the flywheel housing undertakes important functions such as smooth motion, energy transmission and power output. In order to improve the quality and production efficiency of flywheel housings, more and more companies are beginning to use CNC vertical lathe technology for processing.

CNC vertical lathe technology is an efficient and accurate processing method. Through CNC vertical lathes, the flywheel housing can be accurately processed and easily controlled. Compared with traditional manual processing and ordinary vertical lathes, CNC vertical lathe technology has the following advantages:

1. High-precision processing: CNC vertical lathes have high-precision positioning and processing control capabilities, which can ensure the dimensional accuracy and surface flatness of the flywheel housing and improve the overall quality level.

2. High-efficiency production: CNC vertical lathe technology has a high degree of automation and can realize automatic tool changing, automatic correction and other functions, greatly improving production efficiency. At the same time, the multi-station design of CNC vertical lathes also enables one machine tool to process multiple flywheel housings at the same time, further improving production efficiency.

3. Reduce labor costs: Compared with traditional manual processing, CNC vertical lathe technology can reduce workers’ operations and labor intensity, and reduce labor costs.

4. Improve processing quality: CNC vertical lathe technology can achieve precise tool path planning and processing parameter control, avoid processing errors caused by human factors, and ensure the processing quality of the flywheel housing.

CNC vertical turning technology for flywheel housing processing is not only widely used in the field of automobile manufacturing, but also plays an important role in aviation, shipbuilding, machinery manufacturing and other fields. With the continuous development of the automotive industry and product upgrading, the requirements for flywheel housing processing are becoming higher and higher.

| Specification | unit | KD500 | Specification | unit | KD500 |

| X axis | mm | 300 | Turret station | Eight stations + eight stations | |

| Z axis | mm | 500 | X-axis rolling linear guide | 3 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ650 | Z axis rolling linear guide | 4 pieces, width 55mm | |

| turning diameter | mm | Φ500 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 30 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2800*2400*2910mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 10000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды