- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

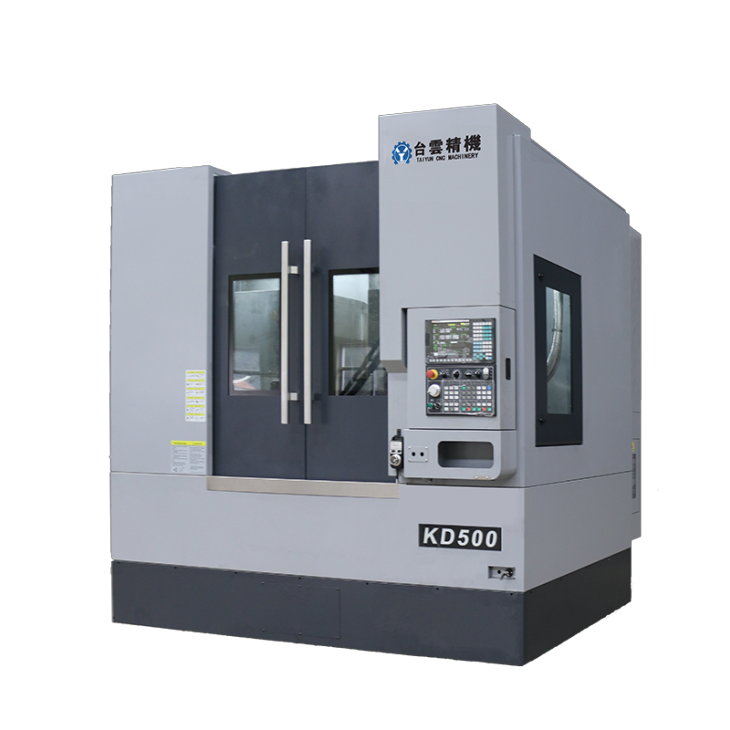

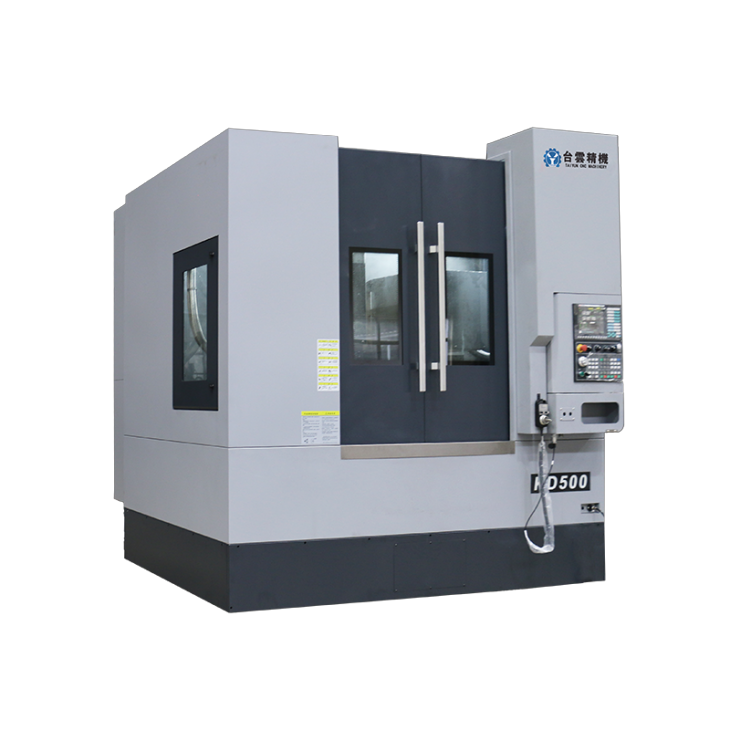

Fully automatic high-precision vertical lathe

A fully automatic high-precision vertical lathe is a highly automated CNC machine tool specifically designed to rotate workpieces in the vertical direction....

A fully automatic high-precision vertical lathe is a highly automated CNC machine tool specifically designed to rotate workpieces in the vertical direction. Here are some of the features and functions typically associated with fully automatic high-precision vertical lathes:

1. CNC system:

Equipped with an advanced CNC system, it can achieve precise tool trajectory control, efficient programming and multi-axis coordinated motion.

2. Automatic tool changing system:

It has an automatic tool changing function and can accommodate multiple tools to achieve automatic tool switching and improve production efficiency.

3. Automatic workpiece clamping:

The automatic clamping system can automatically clamp and release the workpiece according to the preset program, reducing manual intervention.

4. Automatic feeding system:

Equipped with an automatic feeding system, the incoming and outgoing process of workpieces can be automated, improving production efficiency and process continuity.

5. High rigidity machine tool structure:

It has a stable machine tool structure and high rigidity design to resist cutting forces and vibrations to ensure high-precision machining.

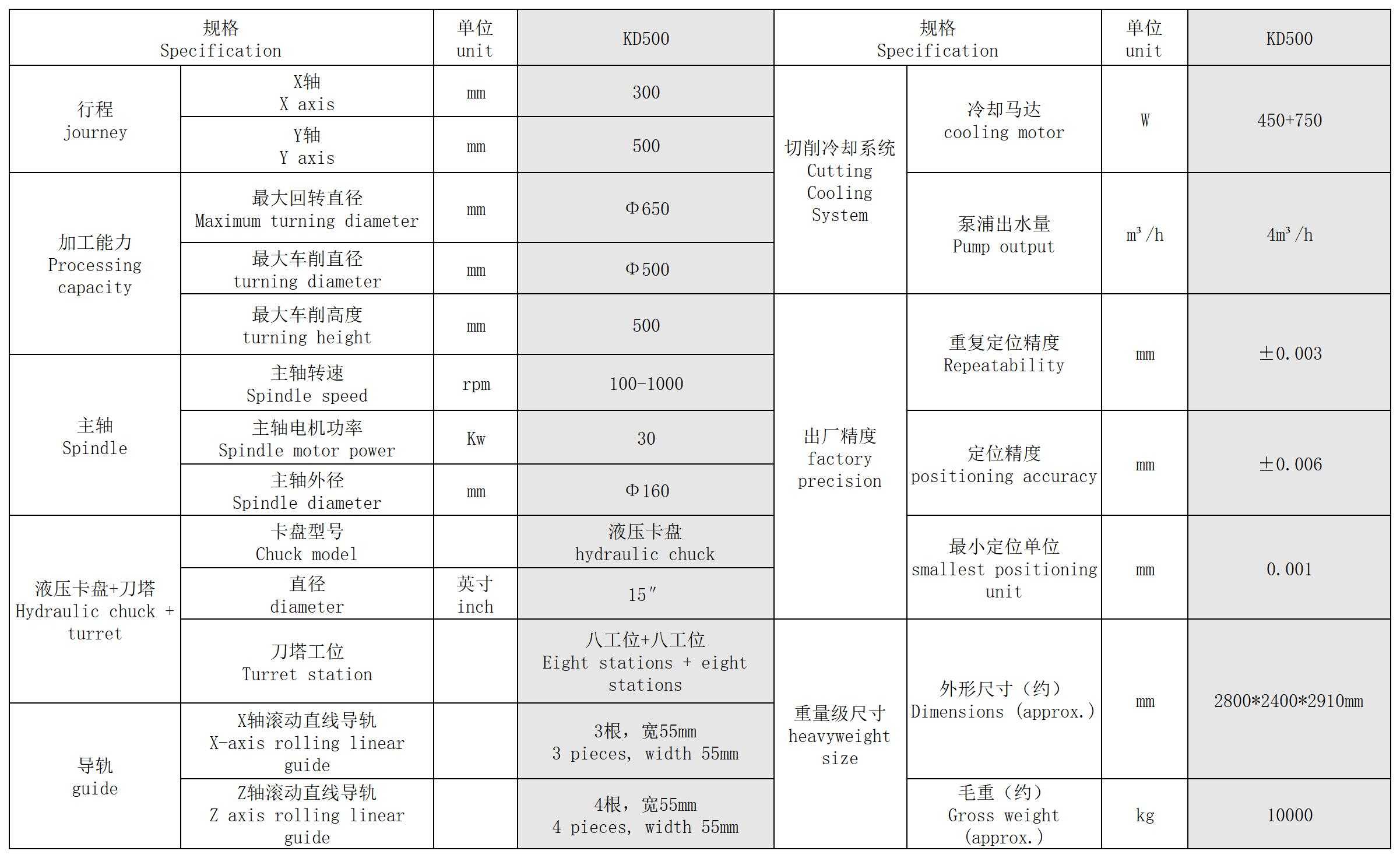

6. High power spindle:

Powerful spindle power adapts to different types of cutting tasks, including heavy cutting and high-speed cutting.

7. Automatic measurement and compensation system:

Equipped with an automatic measurement system, it can monitor tool wear or deformation in real time and automatically compensate to ensure processing accuracy.

8. Remote monitoring and diagnosis:

Supports remote monitoring and diagnostic functions, allowing operators to monitor machine tool status in real time and perform remote fault diagnosis.

9. User-friendly operation interface:

Provides an intuitive user interface that allows operators to easily program, set parameters and monitor the machining process.

10.Safety protection system:

Equipped with a complete safety protection system, including emergency stop, protective cover, etc., to ensure the safety of operators.

These features make fully automatic high-precision vertical lathes ideal for precision parts processing, especially in production environments that require a high degree of automation, efficiency and precision.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды