- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

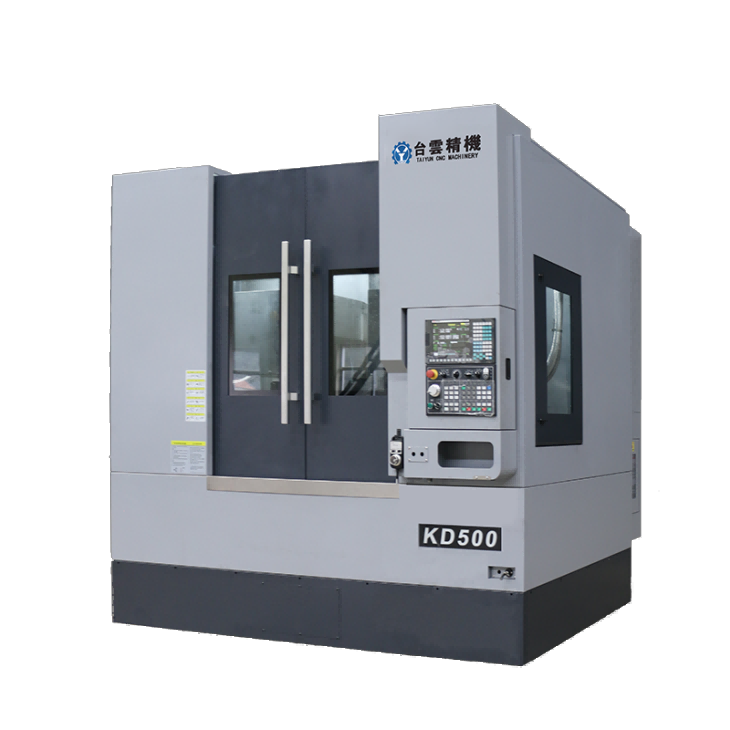

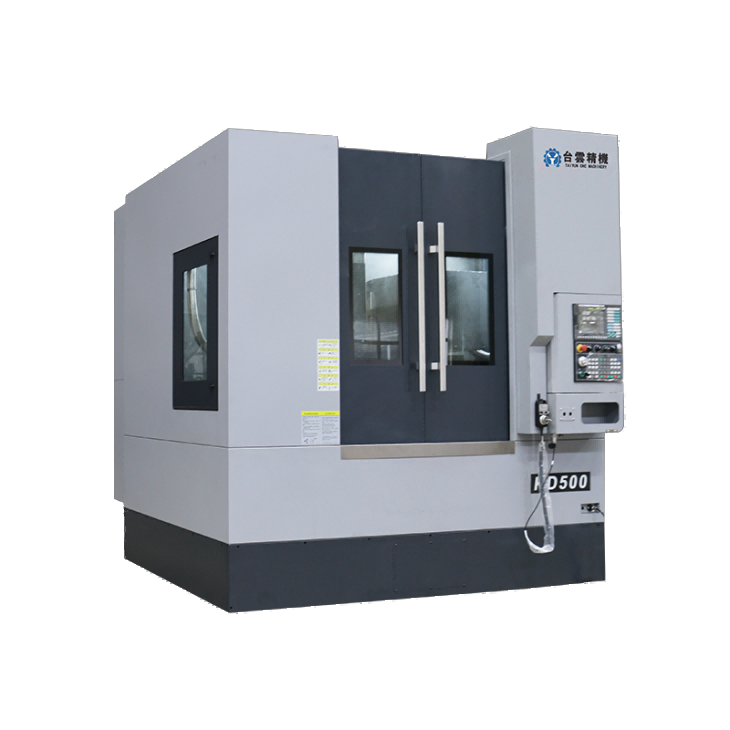

Fully protected double-column CNC vertical lathe

The fully protected high-speed double-column CNC vertical lathe is an advanced mechanical processing equipment that combines the advantages of CNC technology and vertical lathes and has the characteristics of high speed, high efficiency, high precision and high reliability....

The fully protected high-speed double-column CNC vertical lathe is an advanced mechanical processing equipment that combines the advantages of CNC technology and vertical lathes and has the characteristics of high speed, high efficiency, high precision and high reliability. Double-column CNC vertical lathes are mainly used to process various high-precision, multi-batch, and complex-shaped parts, and are widely used in aviation, aerospace, military, automobile, shipbuilding and other industries.

The main features of the fully protected high-speed double-column CNC vertical lathe include:

1. High-speed cutting: The double-column CNC vertical lathe adopts an advanced CNC system and high-speed spindle, which can achieve high-speed cutting and greatly improve processing efficiency.

2. High-precision processing: The double-column CNC vertical lathe has a high-precision measurement and control system, which can ensure the processing accuracy and stability of the double-column CNC vertical lathe and meet the processing requirements of high-precision parts.

3. Full protection design: The double-column CNC vertical lathe adopts a fully enclosed protection design. The double-column CNC vertical lathe can effectively prevent the impact of splash and dust generated during the cutting process on the operator, ensuring operational safety.

4. Double-column structure: The double-column CNC vertical lathe adopts a double-column structure, which has better rigidity and stability. The double-column CNC vertical lathe can withstand greater cutting force and torque, ensuring processing accuracy and stability.

5. Multifunctional tool library: The double-column CNC vertical lathe is equipped with a multi-station turret tool holder. The double-column CNC vertical lathe can automatically replace a variety of tools, improving processing efficiency and automation.

In short, the fully protected high-speed double-column CNC vertical lathe is an efficient, high-precision, and high-reliability mechanical processing equipment. It is suitable for processing various high-precision, multi-batch, and complex-shaped parts. It is indispensable in modern manufacturing. One of the important pieces of equipment that is missing.

| Specification | unit | KD500 | Specification | unit | KD500 |

| X axis | mm | 300 | Turret station | Eight stations + eight stations | |

| Z axis | mm | 500 | X-axis rolling linear guide | 3 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ650 | Z axis rolling linear guide | 4 pieces, width 55mm | |

| turning diameter | mm | Φ500 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 30 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2800*2400*2910mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 10000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды