- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

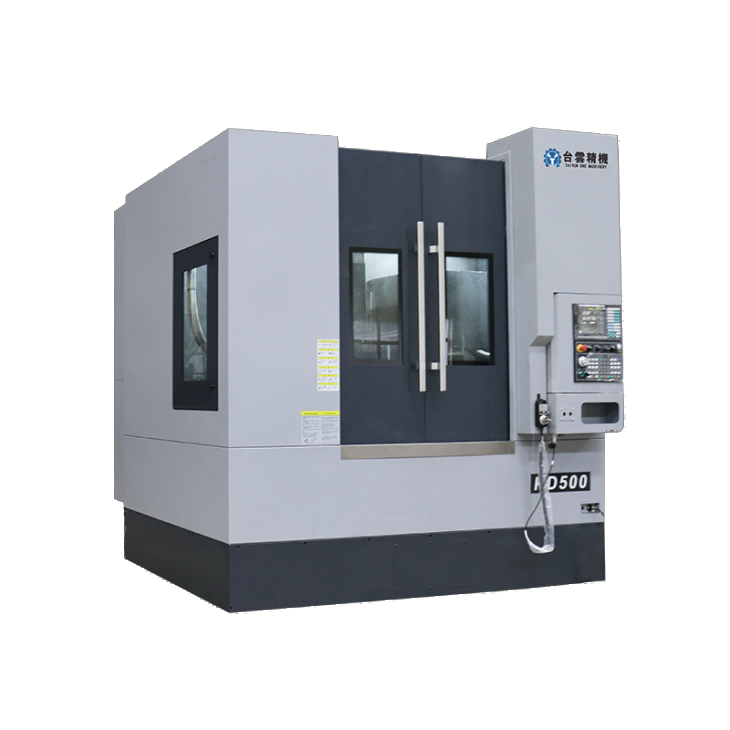

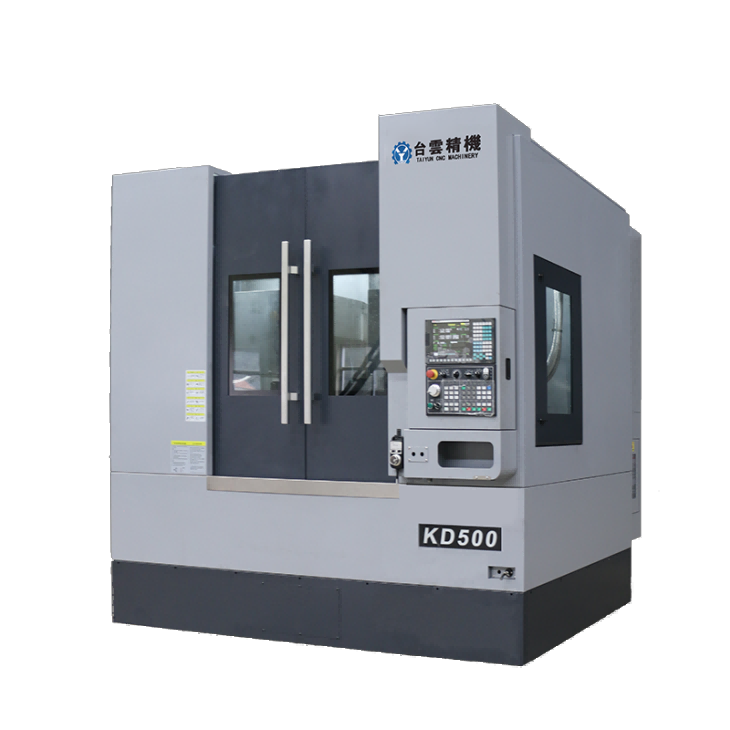

High-precision CNC machine tools

High-precision CNC machine tools are CNC machine tools with high-speed, precision, intelligence, and composite functions. Their development symbolizes the advanced stage of the country's current machine tool manufacturing industry, which accounts for the world's largest share of the world's machine tool industry....

High-precision CNC machine tools are CNC machine tools with high-speed, precision, intelligence, and composite functions. Their development symbolizes the advanced stage of the country's current machine tool manufacturing industry, which accounts for the world's largest share of the world's machine tool industry. The structural design of high-precision CNC machine tools must meet requirements such as high precision, high stiffness, low inertia, low friction, high resonant frequency, and appropriate damping ratio to achieve high machining accuracy and high-speed cutting.

High-precision CNC machine tools are widely used in aerospace manufacturing, automobile manufacturing, electronics manufacturing and other fields. In the field of aerospace manufacturing, due to the very high accuracy and quality requirements for mechanical parts, the advantages of high-precision CNC machine tools such as high automation, high efficiency, high precision and good repeatability have been widely used. In the field of automobile manufacturing, high-precision CNC machine tools are used to process various automobile parts such as engine parts, transmission parts, and steering system parts to meet the high requirements for accuracy and quality of automobile parts. In the field of electronic manufacturing, high-precision CNC machine tools are used to process various electronic components, circuit boards and other electronic parts, improving the efficiency and quality of electronic manufacturing.

In addition, high-precision CNC machine tools also use a series of advanced technologies to improve processing accuracy and efficiency, such as improving the resolution and position detection accuracy of the CNC system, using feedforward control and nonlinear control to reduce CNC system control errors, and applying New control theory realizes high-speed response servo system, etc.

In general, high-precision CNC machine tools are important equipment in modern manufacturing. Their high-precision and high-efficiency characteristics make them play an important role in various manufacturing fields. With the continuous advancement of technology, the performance and functions of high-precision CNC machine tools will be further improved and improved.

| Specification | unit | KD500 | Specification | unit | KD500 |

| X axis | mm | 300 | Turret station | Eight stations + eight stations | |

| Z axis | mm | 500 | X-axis rolling linear guide | 3 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ650 | Z axis rolling linear guide | 4 pieces, width 55mm | |

| turning diameter | mm | Φ500 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 30 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ160 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2800*2400*2910mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 10000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды