- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

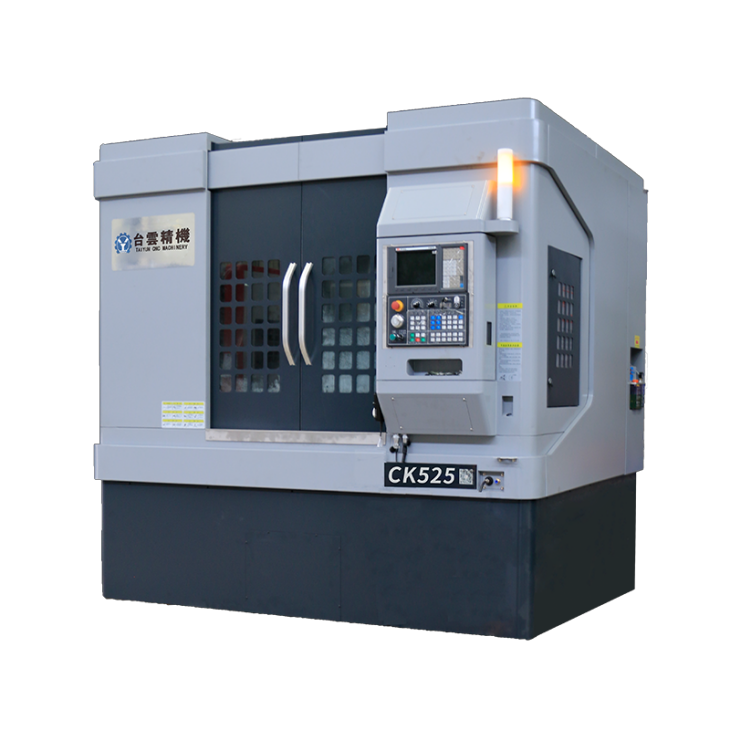

High speed CNC vertical lathe

High-speed CNC vertical lathe is a CNC machine tool specially used for high-speed machining. It has the following characteristics and advantages:...

High-speed CNC vertical lathe is a CNC machine tool specially used for high-speed machining. It has the following characteristics and advantages:

1. High-speed processing capabilities: High-speed CNC vertical lathes have high-speed spindles and high-speed feed systems, which can achieve fast and precise cutting processing. High-speed processing can greatly shorten the processing cycle and improve production efficiency.

2. High-precision processing: Due to the high-precision CNC system and stable structural design, high-speed CNC vertical lathes can achieve high-precision processing and ensure the size and surface quality of processed parts.

3. Versatility: The high-speed CNC vertical lathe has a variety of processing functions and can complete a variety of processing operations such as turning, boring, drilling, and tapping. It is suitable for the processing needs of complex workpieces.

4. High cutting efficiency: High-speed CNC vertical lathes are equipped with high-speed spindles and optimized tool systems, which can complete a large amount of cutting in a short time, improve cutting efficiency, and reduce production costs.

5. Stability and reliability: The high-speed CNC vertical lathe has a reasonably designed machine tool structure and high-quality machine tool parts to ensure stability and reliability during high-speed operation and reduce vibration and deformation during processing.

6. Automated control: The high-speed CNC vertical lathe adopts an advanced CNC system and has automated processing control functions, which can realize automatic tool changing, automatic compensation and other operations, reducing manual intervention.

7. Wide scope of application: High-speed CNC vertical lathes are suitable for processing various materials, including metals, plastics, composite materials, etc., and are used in aerospace, automobiles, molds and other industries.

8. Energy saving and environmental protection: High-speed CNC vertical lathes adopt advanced energy-saving technology and cooling systems to reduce energy consumption and emissions, and meet the energy-saving and environmental protection requirements of modern manufacturing.

In short, the high-speed CNC vertical lathe is an efficient and precise CNC machine tool that can meet the needs of high-speed processing of workpieces and improve production efficiency and processing quality.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды