- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

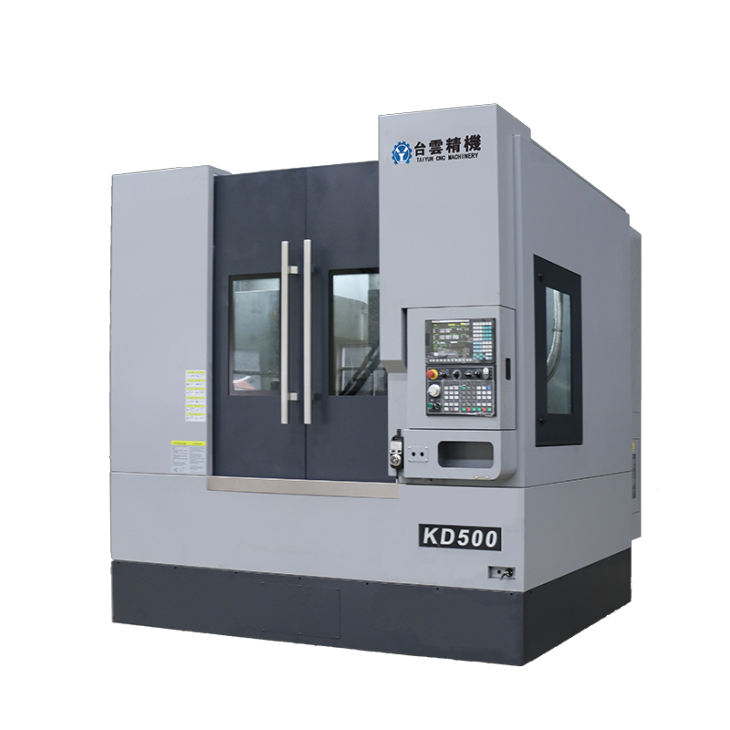

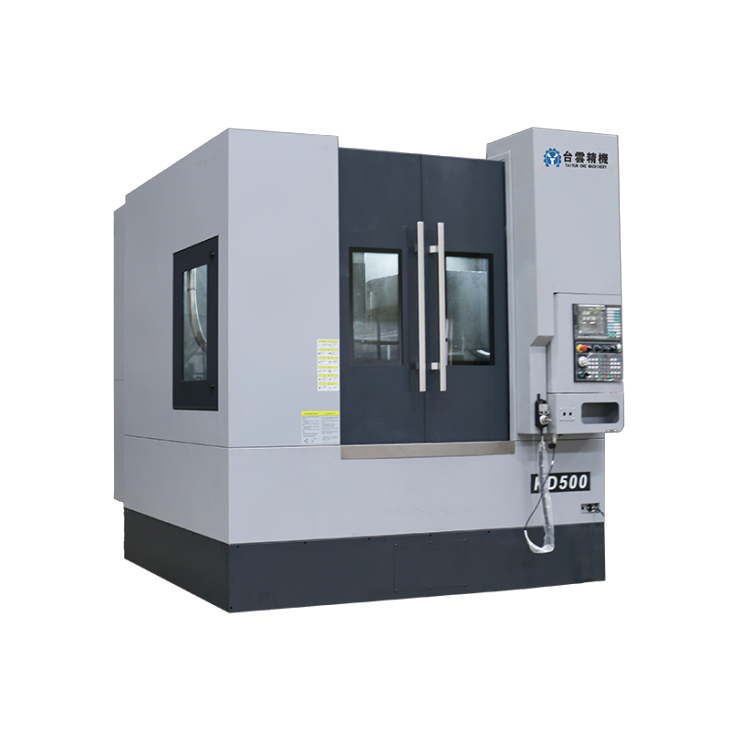

Infinitely variable speed and low failure rate and protection and precision and small CNC vertical lathe

CNC vertical lathe is an advanced processing equipment, which has the characteristics of infinite speed change, low failure rate, strong protection ability, high precision and miniaturization....

CNC vertical lathe is an advanced processing equipment, which has the characteristics of infinite speed change, low failure rate, strong protection ability, high precision and miniaturization. This kind of equipment uses CNC technology to control the processing process, which can achieve optimization of precise processing of workpieces, high-efficiency production, and cost control.

Infinitely variable speed is a major advantage of CNC vertical lathes. This kind of equipment can change the speed according to different workpiece requirements, thereby speeding up the processing speed while ensuring the processing quality. At the same time, the CNC vertical lathe can automatically match according to the different materials of the workpiece to ensure the consistency and stability of the processing quality.

Low failure rate is also a major feature of CNC vertical lathes. Its equipment uses advanced electrical control technology and precision mechanical systems to ensure the stability and reliability of the equipment. At the same time, the production process of the equipment follows a series of standards and specifications, which also improves the durability of the equipment. These characteristics enable the CNC vertical lathe to operate stably for a long time, reduce equipment maintenance costs, and improve production efficiency.

Strong protection ability is an important symbol of CNC vertical lathe. The equipment is equipped with a variety of safety protection devices, such as bearing temperature rise protection, tool clamping failure protection, etc., to ensure safety during the operation. In addition, the equipment is also equipped with an anti-coolant pollution system, which can reduce liquid pollution, ensure processing accuracy, and prevent equipment damage.

High precision is another advantage of CNC vertical lathe. Its equipment has high precision and high repeatability, which can ensure the accuracy and stability of parts within a certain tolerance range. This advantage makes CNC vertical lathes the preferred equipment for manufacturing high-precision, high-quality parts.

Finally, miniaturization is also a major feature of CNC vertical lathes. The equipment is relatively small in size, takes up less area, and can be adapted to different processing sites and environments. In this way, whether in a large manufacturing enterprise or a small workshop, CNC vertical lathes can be easily used to improve production efficiency and product quality.

In short, CNC vertical lathe is an advanced processing equipment with the advantages of infinite speed change, low failure rate, good protection, high precision and miniaturization. This kind of equipment can meet different workpiece processing requirements, improve production efficiency and product quality, and is one of the essential and important equipment in modern manufacturing industry.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды