- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

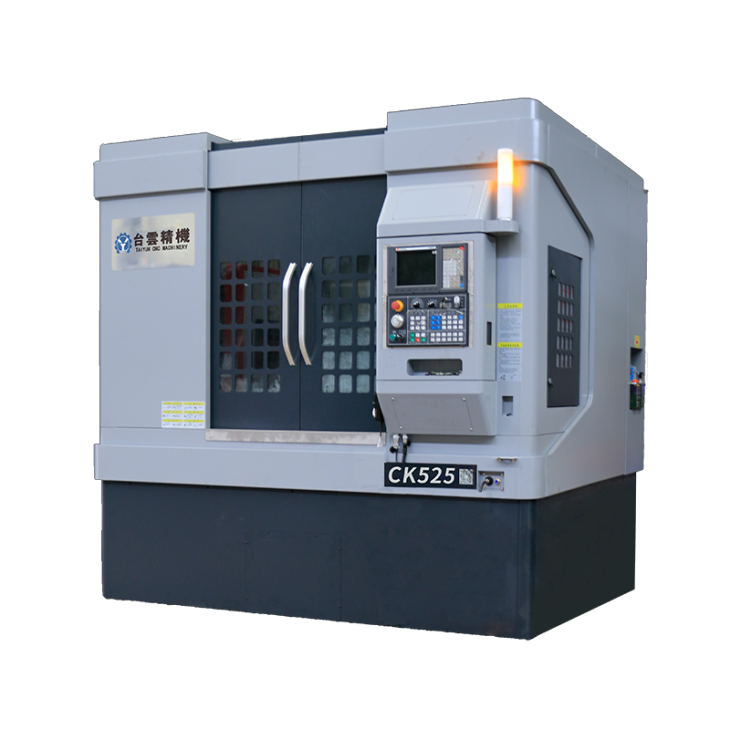

Linear CNC lathe

The linear CNC lathe is an advanced CNC machine tool with a special track structure and control system that can achieve high-precision and high-efficiency metal processing operations....

The linear CNC lathe is an advanced CNC machine tool with a special track structure and control system that can achieve high-precision and high-efficiency metal processing operations.

The linear CNC lathe is mainly composed of the machine tool body, slider, worktable, tool rest, feed system and control system. Among them, the linear rail is a set of precision guide rails on the machine tool body used to support and guide the movement of the slider and worktable. The design and manufacturing quality of the linear rail are crucial to the processing accuracy and stability of the lathe.

The control system is an important part of the linear CNC lathe. It uses computer numerical control technology to control each motion axis of the machine tool through pre-programming to process the workpiece. In the control system, by inputting instructions and parameters, the feed speed, feed amount, cutting depth, and tool motion trajectory of the lathe can be controlled to realize the processing of parts of different shapes.

Linear CNC lathes are widely used in the machining industry, especially for the manufacturing of parts that require high-precision processing. It has the following advantages:

1. High precision: Linear CNC lathes use advanced control systems and precise linear rail structures to achieve high-precision positioning and processing, meeting strict requirements for part size, shape and surface quality.

2. High efficiency: Linear CNC lathes adopt automated control and continuous processing methods, which can achieve high-speed cutting and high-efficiency processing processes, improving production efficiency and processing capabilities.

3. Flexibility: Linear CNC lathes can modify the processing path and cutting parameters through programming to adapt to the processing needs of parts of different shapes and sizes, and have strong flexibility and adaptability.

In general, the linear CNC lathe is a high-precision, high-efficiency processing equipment. Through advanced control systems and precise linear rail structures, it can achieve high-precision processing of complex parts. It is widely used in various mechanical manufacturing and processing field.

| Specification | unit | CK525 | Specification | unit | CK525 |

| X axis | mm | 280 | Turret station | Eight stations + gang knife | |

| Z axis | mm | 500 | X-axis rolling linear guide | 4 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ750 | Z axis rolling linear guide | 4 pieces, width 45mm | |

| turning diameter | mm | Φ550 | cooling motor | W | 450+750 |

| turning height | mm | 500 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-1000 | Repeatability | mm | ±0.003 |

| Spindle motor power | Kw | 18.5 | positioning accuracy | mm | ±0.006 |

| Spindle diameter | mm | Φ140 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2900*2400*2800mm | |

| diameter | inch | 15″ | Gross weight (approx.) | kg | 7000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды