- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Metal automatic vertical lathe

The metal automatic vertical lathe is a machine tool that combines the structure of a vertical lathe and automation technology. It is characterized by efficiency, precision and automation....

The metal automatic vertical lathe is a machine tool that combines the structure of a vertical lathe and automation technology. It is characterized by efficiency, precision and automation. The following are some features and applications of metal automatic vertical lathes:

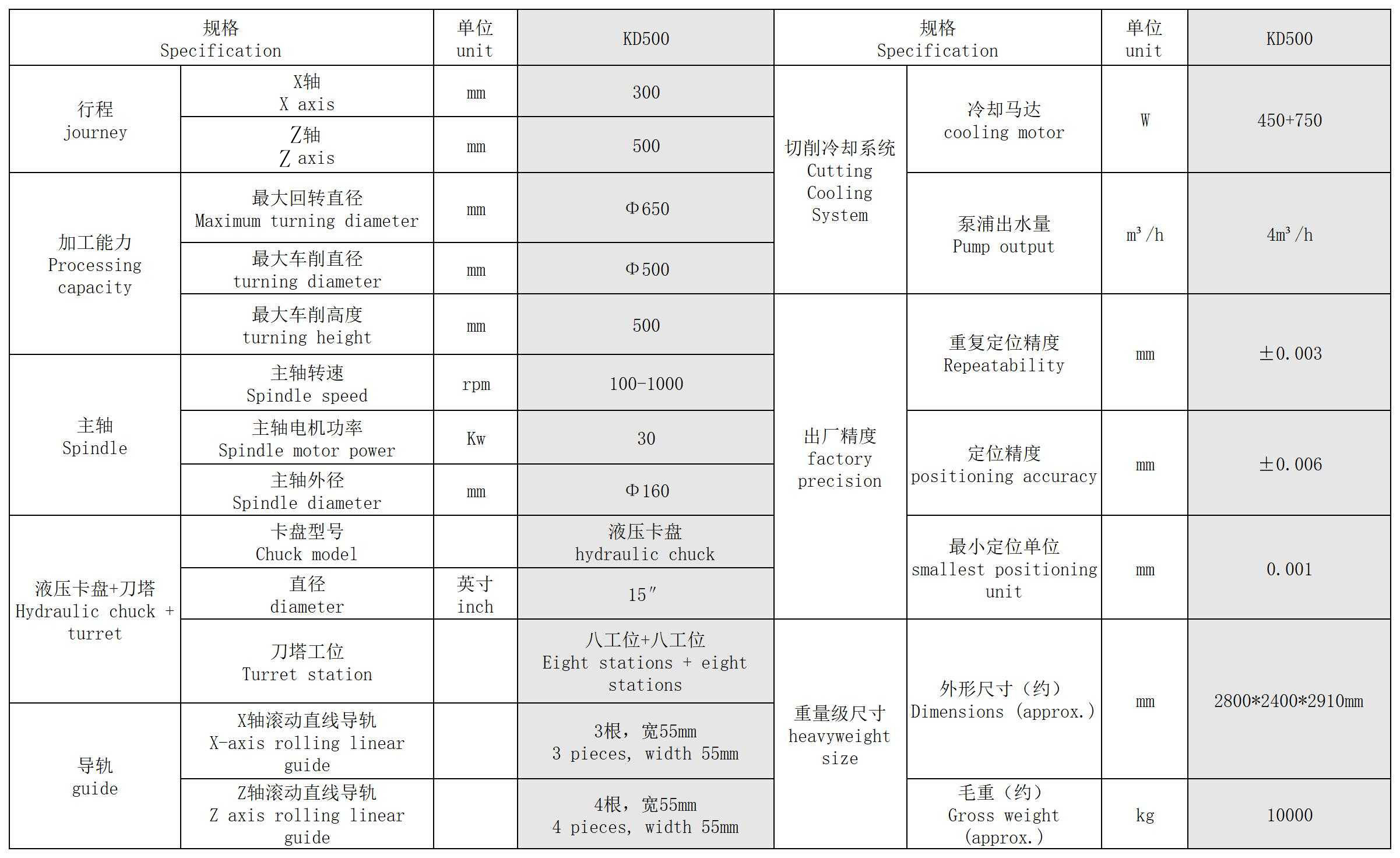

1. Automation system: Metal automatic vertical lathes are equipped with advanced automation systems, including CNC technology, automatic tool changing systems, automatic workpiece clamping systems, etc. These systems enable lathes to perform automated production, reducing manual operations and improving production efficiency.

2. CNC technology: Metal automatic vertical lathes equipped with CNC technology can process through pre-programmed instructions. This means that it can complete complex machining tasks and achieve high-precision and highly repeatable machining operations.

3. Automatic tool change system: Metal automatic vertical lathes are usually equipped with an automatic tool change system, which allows cutting tools to be quickly and automatically changed between different processes, thereby reducing downtime and improving production efficiency.

4. Automatic workpiece clamping system: This system allows machine tools to automatically clamp and release workpieces, improving production efficiency and processing consistency.

5. Monitoring system: Metal automatic vertical lathes are usually equipped with a real-time monitoring system to monitor various parameters during the processing process, including cutting force, temperature, tool wear, etc. This helps to detect problems in time and make adjustments to ensure processing quality.

6. Scope of application: Metal automatic vertical lathes are suitable for processing various metal materials, including steel, aluminum, copper, etc. Due to their automation capabilities, they are particularly suitable for high-volume, high-precision production environments, such as automotive parts manufacturing, aerospace, etc.

7. Ease of operation: Despite its high degree of automation, the operation of metal automatic vertical lathes is usually relatively simple. Operators are primarily required to program and monitor the production process without excessive manual intervention.

Overall, metal automatic vertical lathes have significant advantages in improving production efficiency, reducing labor costs, and ensuring processing accuracy, and therefore are widely used in modern manufacturing.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды