- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

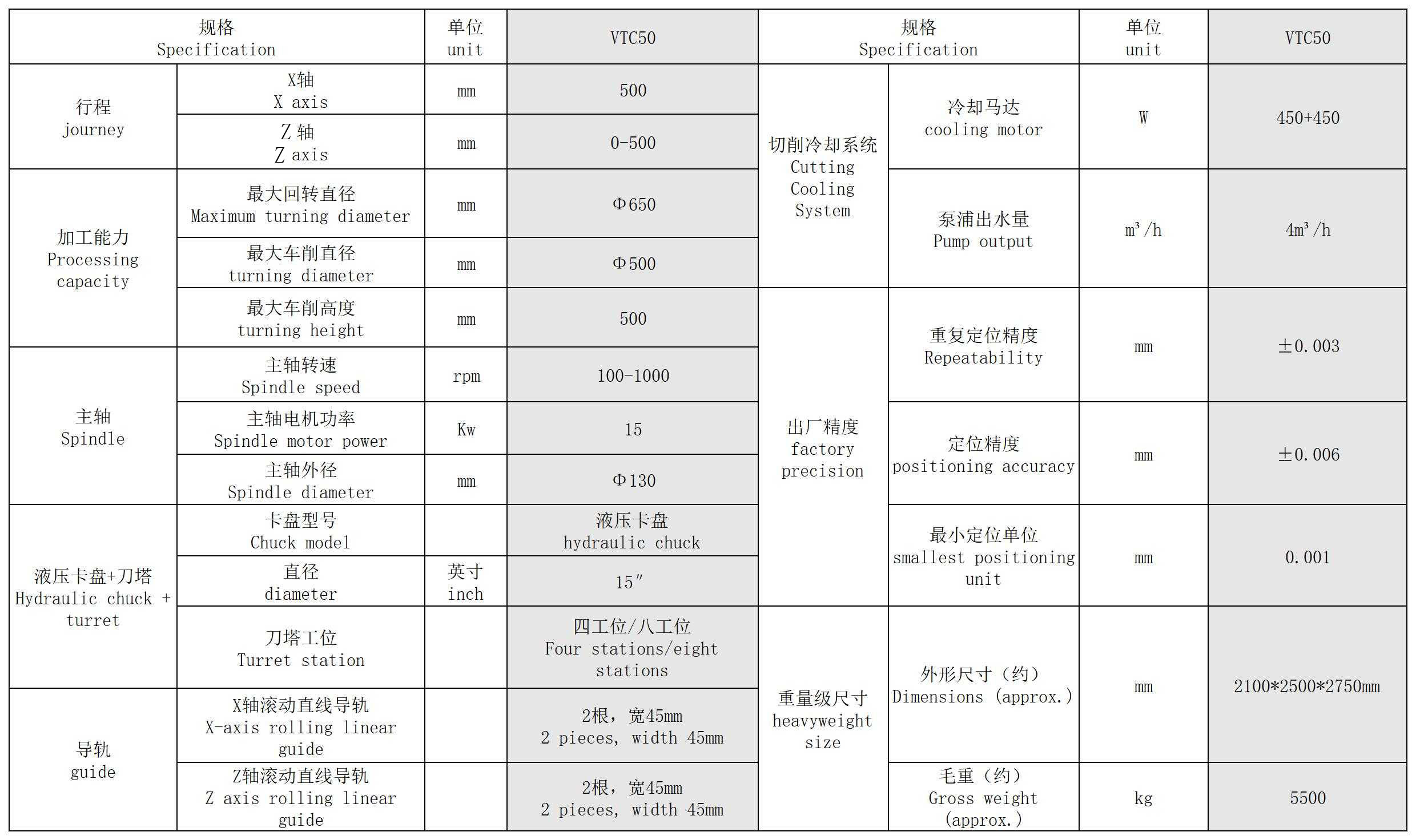

Multipurpose CNC vertical lathe

Multi-purpose, multi-functional, high-speed CNC vertical lathe is an advanced CNC machine tool with a wide range of applications and diverse functional characteristics....

Multi-purpose, multi-functional, high-speed CNC vertical lathe is an advanced CNC machine tool with a wide range of applications and diverse functional characteristics. Here are some of the main features and advantages about this CNC vertical lathe:

1. Versatility: Multifunctional CNC vertical lathes are designed to perform a variety of machining operations such as milling, drilling, tapping, etc. This makes it suitable for different types of workpiece processing, thereby increasing production flexibility.

2. High-speed processing: High-speed CNC vertical lathe has fast feed speed and cutting speed, and can complete the processing of complex parts in a short time. This helps improve production efficiency and reduce processing cycle time.

3. CNC technology: Using advanced CNC technology, automatic control can be achieved through computer programs. Operators can program to specify machining paths, cutting parameters, tool changes, etc., thereby improving the accuracy and consistency of production.

4. High-precision processing: CNC vertical lathes can achieve high-precision processing, ensuring that the size and surface quality of processed parts meet design requirements. This is particularly important for industries that require high precision, such as aerospace and medical device manufacturing.

5. Automatic tool changing system: Equipped with an automatic tool changing system, different types of tools can be quickly and accurately replaced during the processing process, thereby adapting to different processing needs.

6. Rigid structure: CNC vertical lathes usually have a solid machine tool structure and high rigidity to ensure stability during high-speed processing and improve the accuracy of workpiece processing.

7. High-efficiency cooling system: High-speed CNC vertical lathes are usually equipped with an efficient cooling system to ensure that the workpiece and tool can maintain appropriate temperatures during high-speed cutting, thereby extending tool life and improving processing quality.

These characteristics make multi-purpose, multi-function, high-speed CNC vertical lathe an indispensable equipment in modern manufacturing industry, which can adapt to the efficient processing needs of various complex parts.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды