- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

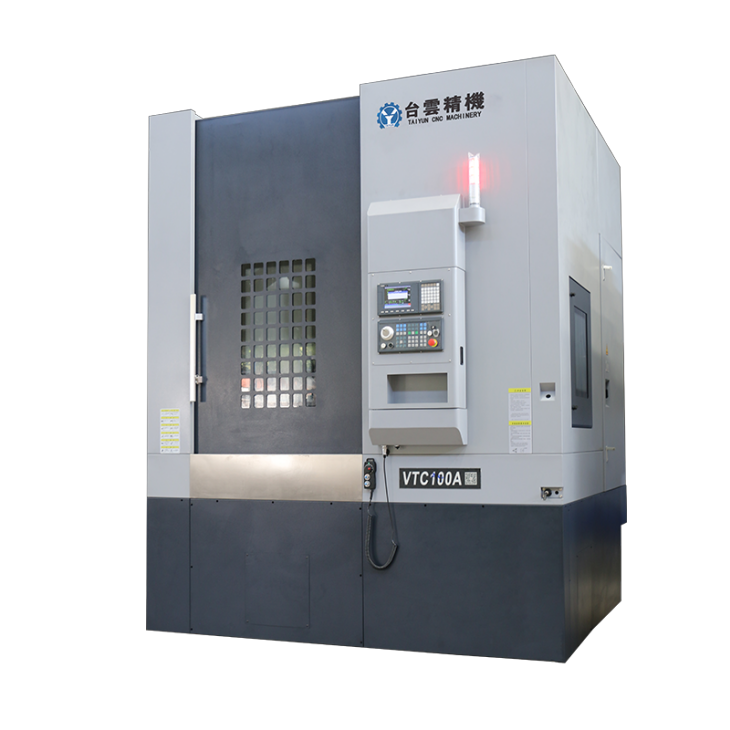

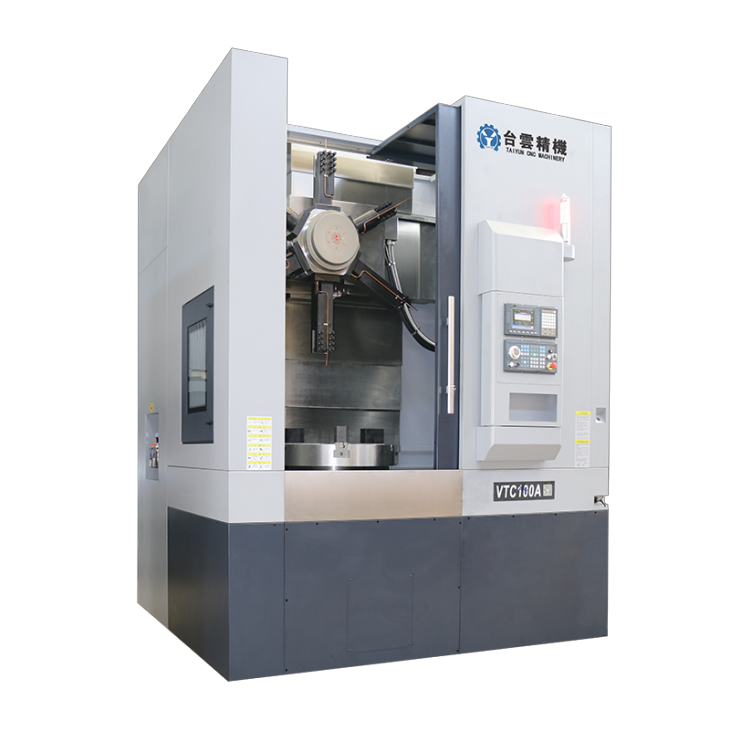

new cnc vertical lathe

The new type of CNC vertical lathe may have some innovations and improvements in CNC technology, structural design, functional expansion, etc. The following are some possible characteristics and advantages:...

The new type of CNC vertical lathe may have some innovations and improvements in CNC technology, structural design, functional expansion, etc. The following are some possible characteristics and advantages:

1. High precision machining: The new CNC vertical lathe adopts advanced CNC technology and precise structural design, which can achieve high-precision machining and meet the machining requirements of various complex workpieces.

2. Efficient production: The new CNC vertical lathe can improve production efficiency, reduce manual intervention, and lower production costs through optimized machining programs and automated machining processes.

3. Multifunctional machining: The new CNC vertical lathe has various machining functions, such as turning, milling, boring, drilling, etc., which can meet the machining needs of different workpieces and improve the versatility and flexibility of the machine tool.

4. Intelligent control: The new type of CNC vertical lathe adopts an intelligent CNC system, which has a graphical programming interface, intelligent diagnostic functions, etc. It is easy to operate, easy to learn and use.

5. Energy conservation and environmental protection: The new CNC vertical lathe adopts the design concept of energy conservation and environmental protection, such as energy-saving spindle drive, lubrication system optimization, etc., which can reduce energy consumption and minimize the impact on the environment.

6. Ergonomic design: The new CNC vertical lathe's ergonomic design makes operation more user-friendly, such as a friendly human-machine interface, convenient operation, and complete safety protection facilities, improving the comfort and safety of operators.

7. Flexible Manufacturing: The new CNC vertical lathe has the ability of flexible manufacturing, which can quickly switch processing tasks, adapt to the processing needs of different workpieces, and improve production flexibility and response speed.

Overall, the new type of CNC vertical lathe has been improved and enhanced in terms of accuracy, efficiency, functionality, intelligence, energy conservation, and environmental protection, which can better meet the needs of modern manufacturing and promote the development and progress of the manufacturing industry.

| Specification | unit | VTC100A | Specification | unit | VTC100A |

| X axis | mm | 850 | Turret station | Four stations | |

| Z axis | mm | 850 | X-axis rolling linear guide | 2 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ1250 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ1200 | cooling motor | W | 750+1200 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 50-800 | Repeatability | mm | ±0.008 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.01 |

| Spindle diameter | mm | Φ200 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2950*2800*3850mm | |

| diameter | inch | Φ1000 | Gross weight (approx.) | KG | 11500 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды