- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

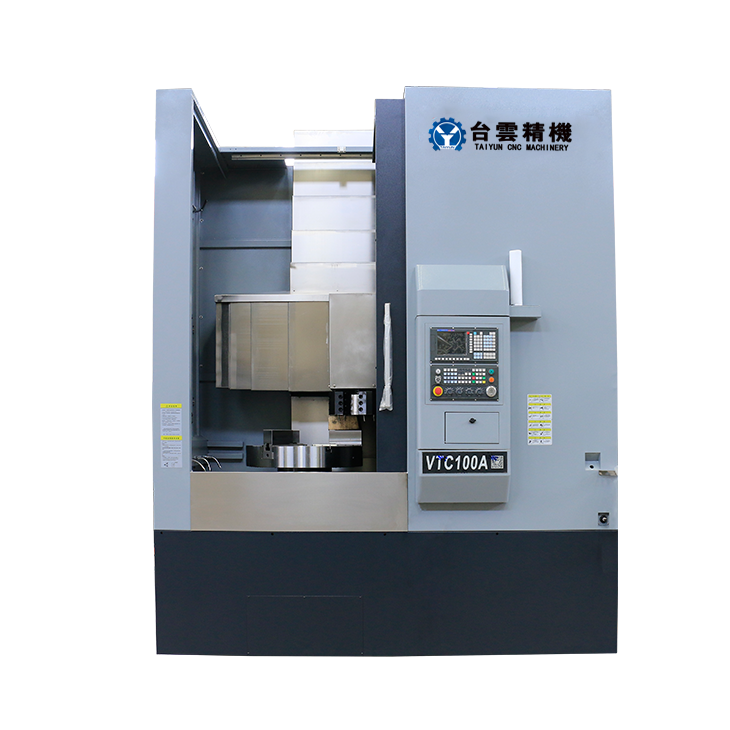

Power tool CNC vertical lathe

CNC vertical lathe with powered tools refers to a CNC vertical lathe that has the function of powered tools....

CNC vertical lathe with powered tools refers to a CNC vertical lathe that has the function of powered tools.

CNC vertical lathe:

1. In CNC vertical lathe, the workpiece is fixed in the horizontal direction, while the tool moves in the vertical direction. This structure makes the processing process relatively stable and is suitable for processing operations such as end faces, inner holes, and outer circles of workpieces.

2. CNC vertical lathes are usually equipped with a CNC system, which controls the movement trajectory and processing depth of the tool through pre-programmed processing programs to achieve precise processing operations.

Power tools:

1. A power tool is a tool with automatic feeding function, which can realize automatic feeding and retraction during processing, thereby improving processing efficiency and accuracy.

2. Power tools usually consist of a driving device, a clamping device and a tool body, and can automatically adjust cutting parameters and processing paths according to instructions from the CNC system.

Features:

1. High precision: The CNC system can accurately control the movement trajectory and cutting parameters of the power tool to ensure machining accuracy.

2. High efficiency: The automatic feeding function of power tools can improve processing efficiency and reduce processing time.

3. Versatility: CNC vertical lathes are equipped with power tools that can perform various complex shape processing operations, such as turning, drilling, milling, etc.

Application areas:

CNC vertical lathes with powered tools are widely used in automobile manufacturing, aerospace, mold processing and other fields to process various metal parts and workpieces, such as bearing seats, bushings, connectors, etc.

CNC vertical lathe with power tool combines CNC technology and power tool technology, has high-precision and high-efficiency processing capabilities, and is suitable for the processing needs of various complex-shaped workpieces.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды