- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

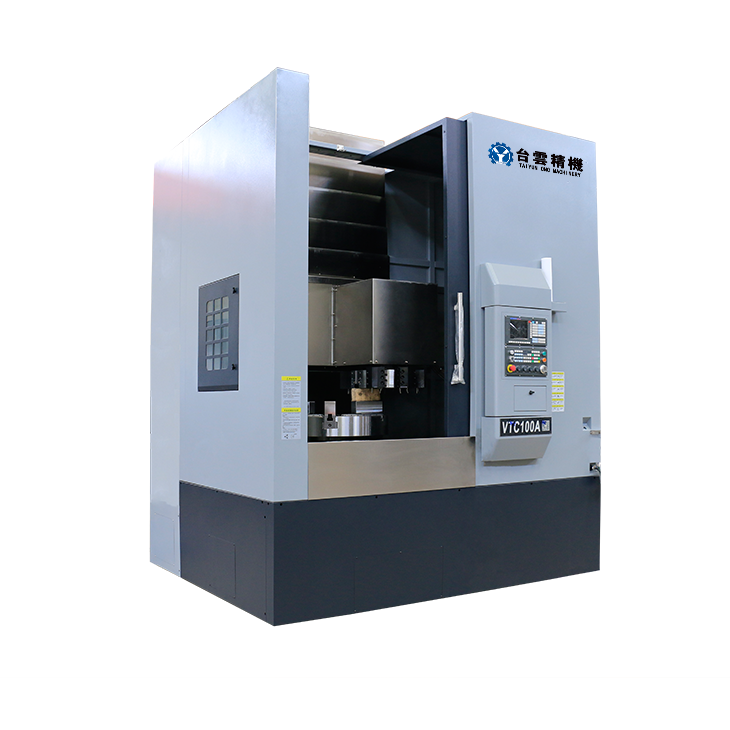

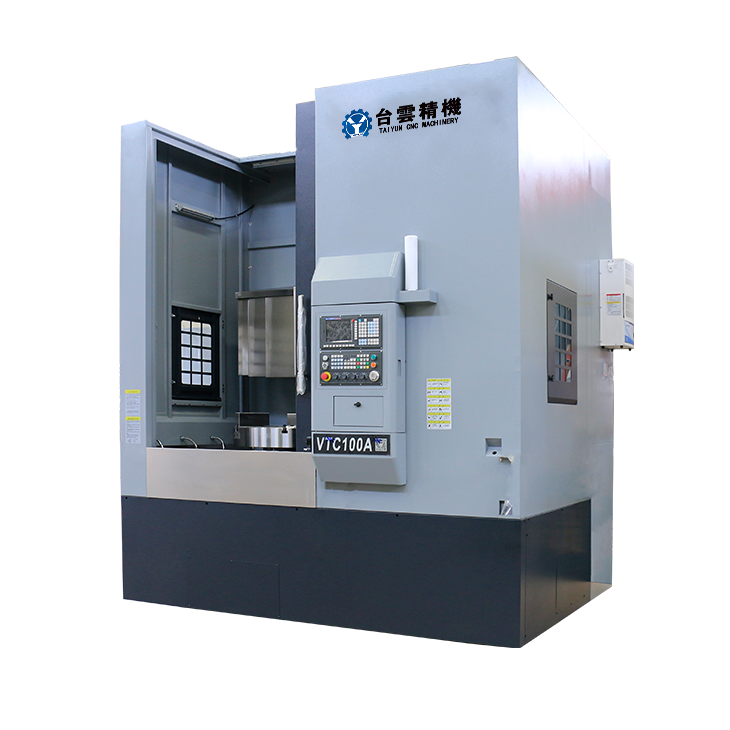

Precision CNC vertical lathe

A precision CNC vertical lathe is a machine tool specially designed for high-precision machining....

A precision CNC vertical lathe is a machine tool specially designed for high-precision machining. The precision CNC vertical lathe adopts a vertical structure, the workpiece is fixed on the workbench, and the cutting tools are precisely controlled by the CNC system to perform various processing operations. Precision CNC vertical lathes have high rigidity and stability, enabling extremely high machining accuracy and surface quality. Due to their precision and reliability, precision CNC vertical lathes are widely used in manufacturing fields, including aerospace, automobile manufacturing, mold processing, etc. The main features and applications of precision CNC vertical lathes are as follows:

main feature:

1. Vertical structure: The spindles of precision CNC vertical lathes are arranged vertically. This layout facilitates the natural shedding of chips and prevents them from accumulating on the workpiece or tool, thus improving the processing quality.

2. CNC operation: Precision CNC vertical lathes use computer numerical control technology to achieve a highly automated processing process. Through programming, precision CNC vertical lathes can perform complex machining paths and operations, improving machining accuracy and repeatability.

3. High-precision machining: Precision CNC vertical lathes are particularly suitable for applications requiring high precision, such as aerospace components, precision molds, etc. The structural design and high-quality guide rails and transmission systems of precision CNC vertical lathes ensure extremely high position accuracy and movement accuracy.

4. Multi-functional processing capabilities: Precision CNC vertical lathes usually have multiple processing functions such as turning, drilling, milling, and grinding. One machine can be used for multiple purposes, improving production efficiency.

Application areas:

1. Aerospace: Precision CNC vertical lathes are used to process engine parts, structural parts, etc. These parts usually require extremely high precision and surface quality.

2. Automobile industry: Precision CNC vertical lathes process key components such as automobile engines and gearbox casings.

3. Mold manufacturing: processing of precision molds, such as plastic injection molds, die-casting molds, etc.

4. Heavy machinery: Precision CNC vertical lathes are used to process large workpieces, such as machine tool beds, large gears, etc.

5. Energy industry: processing of key components such as gearboxes for wind power generation.

By using precision CNC vertical lathes, companies are able to increase production efficiency, reduce labor costs, and maintain consistency and accuracy in product quality.

| Specification | unit | VTC100A | Specification | unit | VTC100A |

| X axis | mm | 850 | Turret station | Four stations | |

| Z axis | mm | 850 | X-axis rolling linear guide | 2 pieces, width 55mm | |

| Maximum turning diameter | mm | Φ1250 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ1200 | cooling motor | W | 750+1200 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 50-800 | Repeatability | mm | ±0.008 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.01 |

| Spindle diameter | mm | Φ200 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2950*2800*3850mm | |

| diameter | inch | Φ1000 | Gross weight (approx.) | KG | 11500 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды