- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

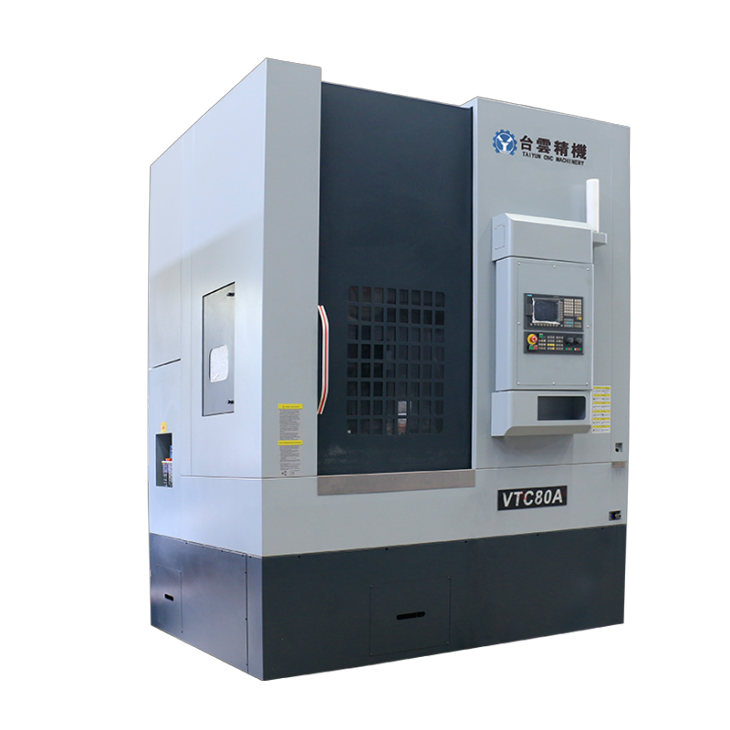

Valve body processing vertical lathe

Valve body processing CNC vertical lathe is a high-performance CNC machine tool specially used for valve body processing....

Valve body processing CNC vertical lathe is a high-performance CNC machine tool specially used for valve body processing. As a key component of the valve, the valve body's CNC vertical lathe processing accuracy and quality have an important impact on the overall performance of the valve. Therefore, it is crucial to choose a suitable CNC vertical lathe for valve body processing.

CNC vertical lathe has the processing characteristics of high precision, high efficiency and high stability, and can meet the complex needs and fine requirements of valve body processing. The working principle of CNC vertical lathe for valve body processing is based on the CNC system to accurately control and operate the vertical lathe tool holder. By quickly rotating the workpiece and moving the tool holder, the valve body can be accurately processed.

During the valve body processing process, CNC vertical lathes can flexibly handle valve bodies of various materials and shapes, and perform fine processing through different tools and processing parameters to ensure that the dimensional accuracy, surface roughness and shape accuracy of the valve body meet the design requirements. At the same time, CNC vertical lathes also have the characteristics of automation and intelligence, which can reduce manual intervention and improve processing efficiency and production efficiency.

In addition, in response to the special requirements of valve body processing, CNC vertical lathes can also be equipped with professional fixtures and auxiliary devices to ensure the stability and safety of the valve body during processing. At the same time, the CNC vertical lathe for valve body processing can further improve the processing quality and production efficiency of the valve body by optimizing the processing technology and parameters.

In summary, the CNC vertical lathe for valve body processing is an indispensable and important equipment in the field of valve manufacturing. Its high-precision, high-efficiency and high-stability processing characteristics provide strong support for the development of the valve manufacturing industry.

| Specification | unit | VTC80A | Specification | unit | VTC80A |

| X axis | mm | 670 | Turret station | Four stations/eight stations | |

| Z axis | mm | 200-1050 | X-axis rolling linear guide | 2 pieces, width 45mm | |

| Maximum turning diameter | mm | Φ1000 | Z axis rolling linear guide | 2 pieces, width 55mm | |

| turning diameter | mm | Φ800 | cooling motor | W | 450+750 |

| turning height | mm | 850 | Pump output | m³/h | 4m³/h |

| Spindle speed | rpm | 100-800 | Repeatability | mm | ±0.005 |

| Spindle motor power | Kw | 22 | positioning accuracy | mm | ±0.008 |

| Spindle diameter | mm | Φ180 | smallest positioning unit | mm | 0.001 |

| Chuck model | hydraulic chuck | Dimensions (approx.) | mm | 2400*2100*3600mm | |

| diameter | inch | 24″ | Gross weight (approx.) | kg | 9000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды