- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

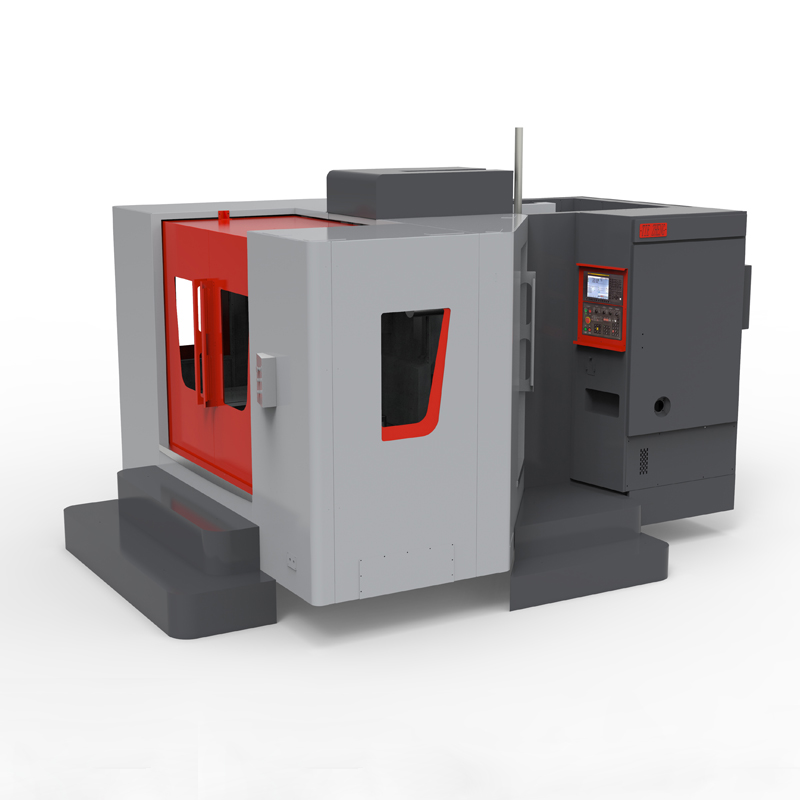

CNC lathe horizontal machining center

CNC lathe horizontal machining center is one of the indispensable and important equipment in modern manufacturing industry....

CNC lathe horizontal machining center is one of the indispensable and important equipment in modern manufacturing industry. With the continuous advancement of science and technology and the rapid development of manufacturing industry, CNC lathe horizontal machining centers play a key role in improving processing efficiency and product quality.

First of all, the CNC lathe horizontal machining center is a piece of equipment that uses a computer control system to achieve automated processing. Its working principle is to use pre-programmed instructions to enable the machine tool to perform processing operations according to the set trajectory and processing parameters to achieve precise processing of the workpiece. Compared with traditional lathes, CNC lathe horizontal machining centers have the advantages of easy operation, high processing accuracy, and high processing efficiency, which greatly improves the accuracy and efficiency of processing.

CNC lathe horizontal machining centers have a wide range of applications. It is suitable for processing various materials and is widely used in aviation, aerospace, automobile, electronics, medical equipment and other industries. For example, in the aerospace field, CNC lathe horizontal machining centers can be used to manufacture engine parts, aircraft structural parts, etc.; in the automotive manufacturing field, CNC lathe horizontal machining centers can be used to manufacture automobile engine blocks, automobile chassis, etc. It can be said that the CNC lathe horizontal machining center is one of the important equipment in modern manufacturing industry.

In addition to its wide range of applications, CNC lathe horizontal machining centers also have many unique technical features. The first is a highly automated machining process. The CNC lathe horizontal machining center can realize the automation of various processing operations through the computer control system, greatly reducing the operator's workload. Second is the highly precise machining capability of the CNC lathe horizontal machining center. CNC lathe horizontal machining centers have high-precision and high-stability processing capabilities, and can reach sub-millimeter or even sub-micron level processing accuracy. In addition, CNC lathe horizontal machining centers also have the characteristics of multi-axis linkage and multi-functional processing, which can meet the processing needs of complex workpieces.

All in all, CNC lathe horizontal machining center is one of the indispensable equipment in modern manufacturing industry. It improves the production efficiency and product quality of the manufacturing industry through automated processing, high-precision processing and other features. With the advancement of science and technology and the continuous expansion of application fields, CNC lathe horizontal machining centers will continue to play an important role in the future and help the efficient development of the manufacturing industry.

| Specifications/model | Unit | WH50A | WH50B | WH63A | WH63B | WH75A | WH75B | WH80A | WH80B | WH100A | WH100B |

| Work content | |||||||||||

| Work surface size (optional) | MM | 500×500 | 500×500 | 630×630 | 630×630 | 750×750 | 750×750 | 800×800 | 800×800 | 1000×1000 | 1000×1000 |

| Workbench indexing (standard) | °C | 0.001 | 0.001 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Customized workbench (optional) | °C | 1/5/90 | 1/5/90 | 0.001/5/90 | 0.001/5/90 | 0.001/5/90 | 0.001/5/90 | 0.001/5/90 | 0.001/5/90 | 0.001/5/90 | 0.001/5/90 |

| Maximum rotation diameter of worktable | MM | 700 | 700 | 1300 | 1300 | 1400 | 1400 | 1600 | 1600 | 1900 | 1900 |

| X-axis travel | MM | 700 | 700 | 1050 | 1050 | 1300 | 1300 | 1300 | 1300 | 1600 | 1600 |

| Y-axis travel (headstock moves up and down) | MM | 600 | 600 | 770 | 770 | 1000 | 1000 | 1000 | 1000 | 1200 | 1200 |

| Z-axis travel | MM | 600 | 600 | 900 | 900 | 950 | 950 | 1000 | 1000 | 1200 | 1200 |

| Distance from spindle center to worktable | MM | 110-190 | 110-190 | 120-890 | 120-890 | 120-1120 | 120-1120 | 120-1120 | 120-1120 | 120-1320 | 120-1320 |

| Distance from spindle end face to worktable center | MM | 200-800 | 200-800 | 170-1070 | 170-1070 | 250-1200 | 250-1200 | 300-1300 | 300-1300 | 400-1600 | 400-1600 |

| Workbench (slot width*number of slots) | MM | 3-14 | 3-14 | 5-22 | 5-22 | 5-22 | 5-22 | 9-24 | 9-24 | 9-24 | 9-24 |

| Threaded hole (optional) | MM | 24-M14 | 24-M14 | 24-M16 | 24-M16 | 24-M16 | 24-M16 | 24-M16 | 24-M16 | 24-M16 | 24-M16 |

| Workbench load-bearing capacity (per block) | KG | 600 | 600 | 1200 | 1200 | 1700 | 1700 | 2100 | 2100 | 3200 | 3200 |

| Spindle and spindle box specifications | |||||||||||

| Spindle taper hole | ISO | BT50-150 | BT50-150 | BT50-190 | BT50-190 | BT50-190 | BT50-190 | BT50-190 | BT50-190 | BT50-190 | BT50-190 |

| Spindle belt speed (standard/optional) | RPM | 6000 | 6000 | 4000, 6000 | 4000, 6000 | 4000, 6000 | 4000, 6000 | 4000, 6000 | 4000, 6000 | 4000, 6000 | 4000, 6000 |

| Transmission gearbox ratio (optional) | N | / | / | 1:1/1:4 | 1:1/1:4 | 1:1/1:4 | 1:1/1:4 | 1:1/1:4 | 1:1/1:4 | 1:1/1:4 | 1:1/1:4 |

| Electric spindle HSK (optional) | HSK | A63 | A63 | A100 | A100 | A100 | A100 | A100 | A100 | A100 | A100 |

| Electric spindle speed | RPM | 18000 | 18000 | 15000 | 15000 | 15000 | 15000 | 15000 | 15000 | 15000 | 15000 |

| Feeding system | |||||||||||

| Shaft Ball Screw Specifications | MM | 40/40/40 | 40/40/40 | 40/40/50 | 40/40/50 | 50/50/50 | 50/50/50 | 50/50/50 | 50/50/50 | 63/63/63 | 63/63/63 |

| X/Y/Z axis rapid movement speed | M/MIN | 32/24/24 | 32/24/24 | 24/24/20 | 24/24/20 | 24/24/20 | 24/24/20 | 24/24/20 | 24/24/20 | 16/16/12 | 16/16/12 |

| B-axis rapid movement speed | M/MIN | B:15 | B:15 | B:10 | B:10 | B:10 | B:10 | B:10 | B:10 | B:10 | B:10 |

| X/Y/Z axis rail specifications | MM | Roller 45/45/45 | Roller 45/45/45 | Roller 55/55/55 | Roller 55/55/55 | Roller 55/55/55 | Roller 55/55/55 | Roller 55/55/55 | Roller 55/55/55 | Roller 55/55/55 | Roller 55/55/55 |

| Motor connection method | / | Direct | Direct | Direct | Direct | Direct | Direct | Direct | Direct | Direct | Direct |

| Main motor parameters | KW | 11 | 11 | 18.5 | 18.5 | twenty two | twenty two | twenty two | twenty two | twenty two | twenty two |

| X/Y/Z axis motor power | NM | 22/22/22B | 22/22/22B | 30/40/30B | 30/40/30B | 30/40/30B | 30/40/30B | 40/40/30B | 40/40/30B | 40/40/30B | 40/40/30B |

| B-axis motor power | NM | B:8 | B:8 | B:12 | B:12 | B:22 | B:22 | B:22 | B:22 | B:30 | B:30 |

| Axis positioning accuracy | MM | 0.01 | 0.01 | 0.012 | 0.012 | 0.012 | 0.012 | 0.013 | 0.013 | 0.015 | 0.015 |

| Axis item repeat positioning accuracy | MM | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.006 | 0.006 | 0.006 | 0.006 |

| BPositioning accuracy | SEC | 10" | 10" | 10" | 10" | 10" | 10" | 10" | 10" | 10" | 10" |

| B Repeat positioning accuracy | SEC | 3" | 3" | 3" | 3" | 3" | 3" | 3" | 3" | 3" | 3" |

| Minimum move value | MM | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Oil and gas pressure system | |||||||||||

| air pressure | KG/MM | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 |

| coolant capacity | L | 450 | 450 | 550 | 550 | 600 | 600 | 650 | 650 | 750 | 750 |

| Lubricating oil capacity L | L | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Total power capacity | KVA | 35 | 37 | 40 | 42 | 45 | 47 | 45 | 47 | 45 | 45 |

| Toolholder/Tool Magazine System (specify when ordering) | |||||||||||

| Tool magazine structure | / | Disc knife arm type | Disc knife arm type | Disc knife arm type | Disc knife arm type | Disc knife arm type | Disc knife arm type | Disc knife arm type | Disc knife arm type | Disc knife arm type | Disc knife arm type |

| Number of tool magazines (optional) | T | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 | 24, 32, 40 |

| Knife inventory structure (optional) | / | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type | Chain plate type |

| Number of tool magazines | T | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 | 40/50/60/80 |

| Tool changing time T | SEC | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 | 3.8/5.2 |

| Maximum tool weight (optional) KGS | 8/10 | 8/10 | 15/18 | 15/18 | 15/18 | 15/18 | 15/18 | 15/18 | 15/18 | 15/18 | 15/18 |

| Maximum tool/adjacent tool clearance diameter | MM | φ110/φ200 | φ110/φ200 | φ110/φ200 | φ110/φ200 | φ110/φ200 | φ110/φ200 | φ110/φ200 | φ110/φ200 | φ110/φ200 | φ110/φ200 |

| Form factor | |||||||||||

| Weight approx. | KG | 5.5 | 6.5 | 12.5 | 15.5 | 14 | 17 | 18.5 | 22.5 | 19.5 | 19.5 |

| Machine length | MM | 3500 | 4800 | 4800 | 6100 | 5100 | 7000 | 5350 | 7200 | 5300 | 5300 |

| Machine width | MM | 3100 | 3300 | 3400 | 4150 | 4200 | 5500 | 4200 | 5680 | 4500 | 4500 |

| Machine height (maximum) | MM | 3200 | 3200 | 3400 | 4550 | 4400 | 4400 | 4400 | 4400 | 4700 | 4700 |

| Machine tool structure | / | Positive T shape | Positive T shape | Inverted T shape | Inverted T shape | Inverted T shape | Inverted T shape | Inverted T shape | Inverted T shape | Inverted T shape | Inverted T shape |

| Chip removal method | / | Twin screw rear row | Twin screw rear row | Twin screw single chain plate | Twin screw single chain plate | Twin screw single chain plate | Twin screw single chain plate | Twin screw single chain plate | Twin screw single chain plate | Twin screw single chain plate | Twin screw single chain plate |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды