- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

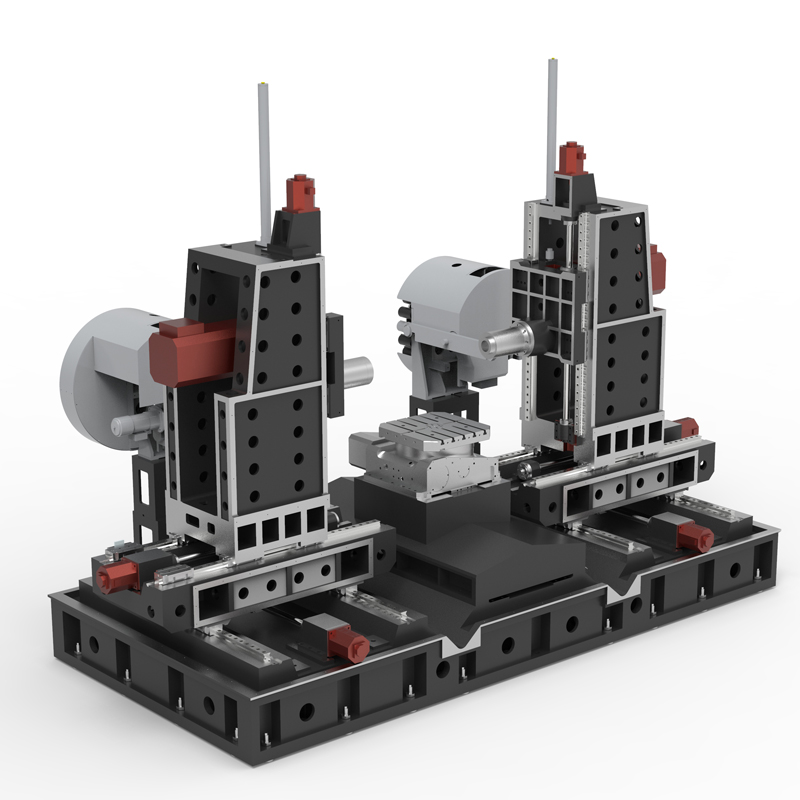

Horizontal machining center high power

The high power of a horizontal machining center usually refers to the power of its spindle motor....

The high power of a horizontal machining center usually refers to the power of its spindle motor. High-power spindle motors have the following advantages:

1. Powerful processing capabilities: The high-power spindle motor of the horizontal machining center can provide greater cutting force and torque, and can adapt to more complex and heavy-duty processing tasks, including high-speed cutting and precision machining of hard materials.

2. High processing efficiency: The high-power spindle motor of the horizontal machining center can achieve higher cutting speed and feed rate, faster processing speed and higher production efficiency, which helps to shorten the processing cycle and improve production efficiency.

3. Wide range of applications: The high-power spindle motor of the horizontal machining center can process various materials, including metals, plastics, composite materials, etc. The horizontal machining center can meet the processing needs of different industries and application fields.

4. High processing accuracy: High-power spindle motors of horizontal machining centers are usually equipped with high-precision rotors and bearings, which can maintain stable processing accuracy and ensure that the size and surface quality of parts processed by the horizontal machining center meet the requirements.

5. Improve equipment performance: The high-power spindle motor of the horizontal machining center can improve the overall performance of the horizontal machining center, making it have stronger processing capabilities and adaptability to meet the requirements of different processing tasks.

In general, horizontal machining centers equipped with high-power spindle motors can improve the processing capabilities, efficiency and accuracy of the equipment, and provide users with more powerful and efficient processing solutions.

| Specifications/model | Unit | WHH50 | WHH63 | WHH80 | WHH100 |

| Work content | |||||

| Turntable table size WHA | MM | 500×500 | 630×630 | 800×800 | 1000×1000 |

| Fixed table size WHF (optional) | MM | 1000×500 | 1300×600 | 1300×600 | 1600×1000 |

| Number of worktables (optional translational double work) | N | Single/Double | Single/Double | Single/Double | Single/Double |

| Workbench indexing (standard) | N | 1 degree 1 minute | 1 degree 1 minute | 1 degree 1 minute | 1 degree 1 minute |

| Workbench (optional) | N | Other graduations can be customized | Other graduations can be customized | Other graduations can be customized | Other graduations can be customized |

| Maximum rotation diameter of worktable | MM | 1000 | 1300 | 1300 | 1600 |

| X1.X2 axis travel | MM | 800 | 1000 | 1000 | 1300 |

| Y1.Y2 axis travel (spindle item moves up and down) | MM | 700 | 700 | 700 | 700 |

| Z1.Z2 axis stroke | MM | 500 | 900 | 900 | 900 |

| Distance from spindle center to worktable | MM | 110-810 | 110-810 | 110-810 | 110-810 |

| Distance from spindle end face to worktable center | MM | 200-700 | 200-1100 | 200-1100 | 200-1100 |

| T-shaped workbench (slot width * number of slots) | MM | 22-3 | 22-3 | 22-5 | 22-5 |

| Workbench load-bearing | KG | 2000 | 2500 | 3200 | 5000 |

| Spindle and spindle box specifications | |||||

| Spindle taper hole (model/installation dimensions) | ISO | BT40-150 | BT50-190 | BT50-190 | BT50-190 |

| Spindle speed mark (optional) | RPM | 4000/8000/12000 | 4000/6000 | 4000/6000 | 4000/6000 |

| Feeding system | |||||

| X.Y.Z axis screw specifications | MM | 40/40/40 | 50/50/50 | 50/50/50 | 63/50/50 |

| X-axis rapid movement speed | M/MIN | X:48 | X:32 | X:32 | X:24 |

| Y-axis rapid movement speed | M/MIN | Y:48 | Y:32 | Y:32 | Y:24 |

| Z-axis rapid movement speed | M/MIN | Z:48 | Z:32 | Z:32 | Z:24 |

| X/Y/Z axis wire gauge specifications | MM | Roller 45/45/45 | Roller 55/55/55 | Roller 55/55/55 | Roller 55/55/55 |

| X/Y/Z motor connection method | / | direct connection | direct connection | direct connection | direct connection |

| main motor power | KW | 11 | 18.5 | 18.5 | 18.5 |

| X-axis motor power | NM | 22/22B/22 | 27/27B/27 | 27/27B/27 | 30/30B/30 |

| B-axis motor power | NM | B:8 | 12 | 12 | 22 |

| Axis positioning accuracy | MM | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Axis item repeat positioning accuracy | MM | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| BPositioning accuracy | MM | 8” | 8” | 8” | 8” |

| B Repeat positioning accuracy | MM | 5” | 5” | 5” | 5” |

| Minimum move value | MM | 0.001 | 0.001 | 0.001 | 0.001 |

| Oil and gas pressure system | |||||

| air pressure | KG | 7 | 7 | 7 | 7 |

| coolant capacity | L | 550 | 650 | 650 | 850 |

| Lubricating oil capacity L | L | 4 | 4 | 4 | 4 |

| Toolholder/Tool Magazine System (specify when ordering) | |||||

| Tool magazine structure | / | Robotic arm | Robotic arm | Robotic arm | Robotic arm |

| Number of tool magazines | T | 24 | 24 | 24 | 24 |

| Tool changing time T-T | MM | 3 | 7 | 7 | 7 |

| Maximum tool weight | KGS | 8 | 12 | 12 | 12 |

| Form factor | |||||

| Weight approx. | KG | 10/11 | 19/20 | 21/22 | 28/30 |

| Machine length | MM | 5500 | 7500 | 7500 | 9500 |

| Machine width | MM | 3800 | 4500 | 4500 | 5500 |

| Machine height (maximum) | MM | 3300 | 3700 | 3700 | 4200 |

| Machine height (minimum) | MM | 3000 | 3300 | 3300 | 3600 |

| Chip removal method | / | win screw + single chain plate | win screw + double chain plate | win screw + double chain plate | win screw + double chain plate |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды