- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

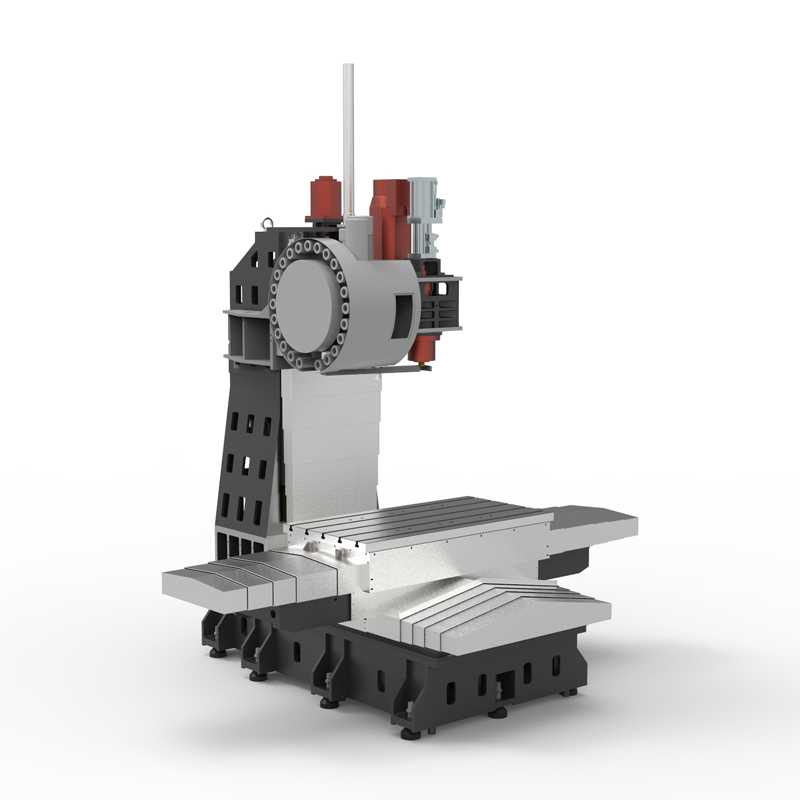

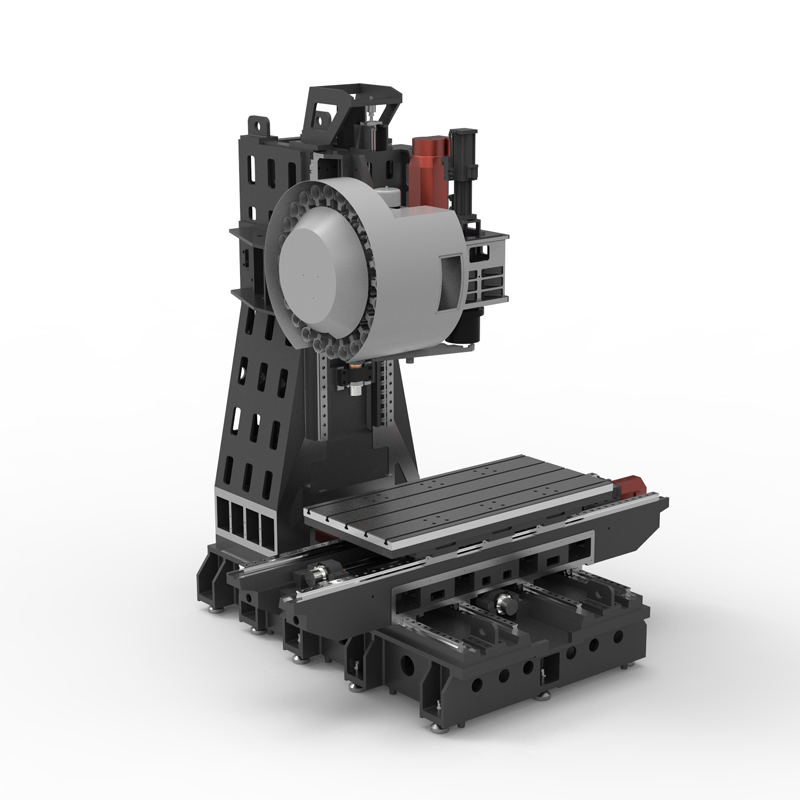

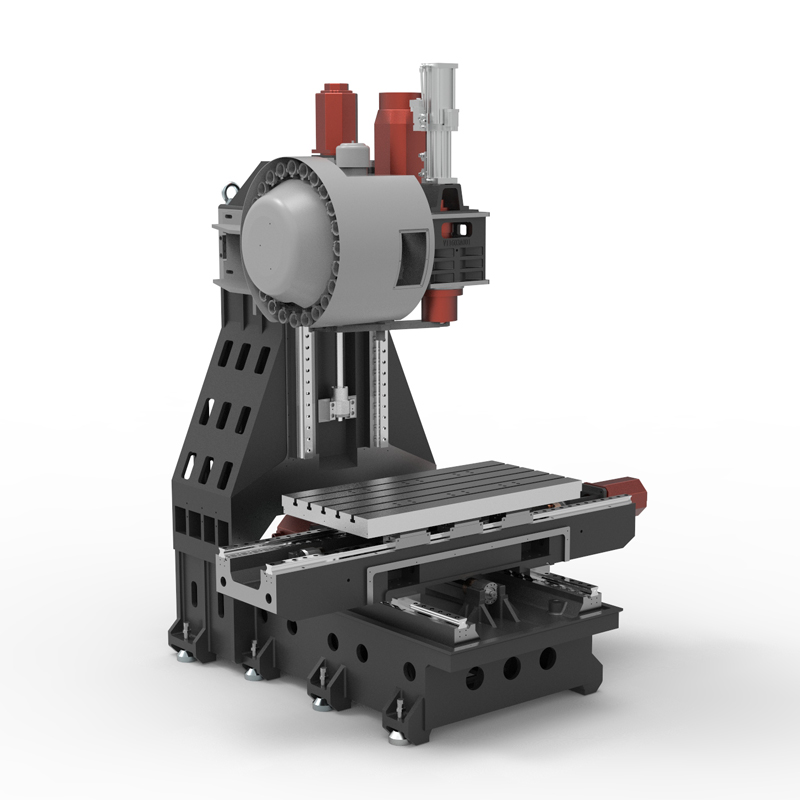

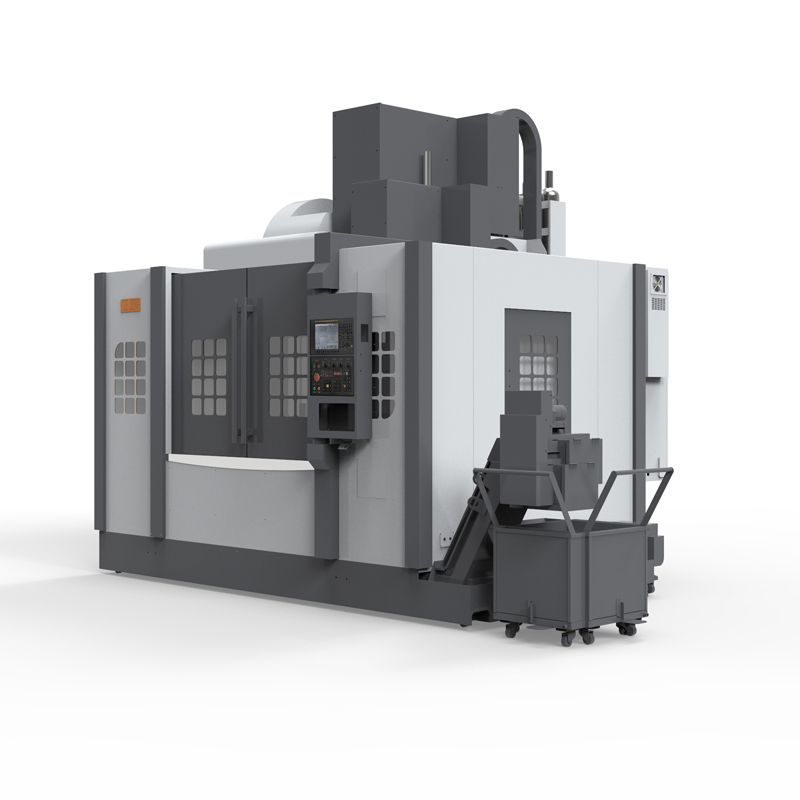

Automatic cutting CNC machining center

The automatic cutting CNC machining center is a high-precision and high-efficiency machine tool with automated cutting processing functions and CNC system control....

The automatic cutting CNC machining center is a high-precision and high-efficiency machine tool with automated cutting processing functions and CNC system control. The following are some features and applications of automatic cutting CNC machining centers:

Features:

1. Automated processing: The automatic cutting CNC machining center has an automated tool changing system, workpiece clamping system and processing process control, which can realize automated production and processing and improve production efficiency.

2. High-precision processing: The automatic cutting CNC machining center is equipped with a high-precision CNC system and a stable mechanical structure, which can achieve high-precision processing of workpieces and meet the processing requirements of complex workpieces.

3. Multi-function processing: Automatic cutting CNC machining centers usually have a variety of processing functions, including milling, drilling, boring, tapping, etc., which can meet the processing needs of different workpieces.

4. Flexibility: Under the control of the CNC system, the processing program can be flexibly adjusted and modified to adapt to the processing requirements of different workpieces, improving the flexibility and adaptability of production.

5. High-efficiency production: Automatic cutting CNC machining centers can achieve continuous, high-speed, and high-efficiency production and processing, reduce manual intervention, and improve production efficiency and product quality.

application:

1. Automobile manufacturing: Automatic cutting CNC machining centers are used to process automobile parts, engine parts, body structures, etc., to meet the needs of the automobile manufacturing industry for high-precision and high-efficiency production.

2. Aerospace: Automatic cutting CNC machining centers are used in the processing of aircraft parts, engine parts, spacecraft structures, etc. in the aerospace field, and have high precision and complex shape requirements.

3. Mold manufacturing: Automatic cutting CNC machining centers are used for processing workpieces such as molds, templates and models. They can achieve high-precision processing of complex shapes and improve the quality and efficiency of mold manufacturing.

4. Electronic equipment: The automatic cutting CNC machining center is suitable for processing parts of electronic equipment, such as circuit boards, shell structures, etc., to meet the demand for high-precision processing of electronic products.

Automatic cutting CNC machining center is an important equipment in modern manufacturing industry. It is widely used in the production and processing fields of various industries. It can achieve high-precision and high-efficiency processing and production, and improve production efficiency and product quality.

| Specifications/model | unit | V966 | V1160 | V1168 | V1270 | V1377 | V1387 | V1380C | V1680C | V2010C |

| Work content | ||||||||||

| working desk size | MM | 1100×700 | 1200×600 | 1200×600 | 1300×700 | 1400×7010 | 1400×800 | 1400×800 | 1700×800 | 2100×1000 |

| Workbench travel (X/Y/Z) | MM | 900×600×600 | 1100×600×600 | 1100×600×800 | 1200×700×600 | 1300×700×700 | 1300×800×700 | 1300×800×70 | 1600×800×700 | 2000×1000×800 |

| Distance from spindle nose to work surface | MM | 150-750 | 120-720 | 120-920 | 120-720 | 120-820 | 120-820 | 150-850 | 150-850 | 150-950 |

| Distance from spindle center to column track surface | MM | 700 | 660 | 660 | 780 | 780 | 900 | 900 | 900 | 1100 |

| Maximum load of workbench | KG | 700 | 1000 | 1000 | 1100 | 1300 | 1400 | 1500 | 1800 | 2200 |

| Spindle specifications | ||||||||||

| Spindle transmission structure (standard) | / | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type | Belt type |

| Spindle speed | RPM | 8000 | 8000 | 8000 | 8000 | 8000 | 8000 | 6000 | 6000 | 6000 |

| Spindle transmission structure (optional) | / | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection | direct connection |

| Spindle speed | RPM | 12000 | 12000 | 12000 | 10000 | 10000 | 10000 | 10000 | 10000 | 10000 |

| Spindle power | KW | 11 | 11 | 11 | 15 | 15 | 15 | 15/18.5 | 18.5/22 | 18.5/22 |

| Spindle bore taper | BT | BT40-150 | BT40-150 | BT40-150 | BT40-150 | BT40-150 | BT40-150 | BT50-190 | BT50-190 | BT50-190 |

| Feed content | ||||||||||

| G00 rapid feed | M/MIN | 48/48/48 | 36/36/36 | 36/36/36 | 32/32/32 | 32/32/32 | 32/32/32 | 24/24/24 | 24/24/24 | 24/24/24 |

| G01 cutting feed | MM/MIN | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Servo motor specifications | NM | 22/22/22B | 22/22/22B | 22/22/22B | 22/22/22B | 22/22/22B | 22/22/22B | 40/30/30B | 40/30/30B | 40/30/30B |

| Servo motor speed | RPM | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 2000 | 2000 | 002000 |

| Motor connection method | / | Direct | Direct | Direct | Direct | Direct | Direct | Direct | Direct | Direct |

| Ball screw specifications | MM | 4016/12 | 4012 | 4012 | 4012 | 4012 | 4012 | 5010 | 5010 | 5010/6310 |

| X-axis rail specifications | MM | 45 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 55*3 roller | 55*3 roller | 55*3 roller |

| Y axis rail specifications | MM | 45 roller | 45 roller | 45 roller | 45 roller | 45 roller | 45 roller | 45 rollers*4 rails | 45 rollers*4 rails | 45 rollers*4 rails |

| Z axis rail specifications | MM | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 45*3 roller | 55*3 roller | 55*3 roller | 55*3 roller |

| Z-axis VB hard rail (optional) | / | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail | hard rail |

| Precise shaft positioning | MM | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatable positioning precision | MM | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| Minimum move value | MM | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Tool magazine system | ||||||||||

| Tool magazine structure | / | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type | Knife arm type |

| Tool magazine capacity | PCS | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Tool changing time | MM | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 4 |

| Maximum tool weight | KG | 8 | 8 | 8 | 8 | 8 | 8 | 18 | 18 | 18 |

| Oil and gas pressure system | ||||||||||

| air pressure | KG/MM | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 |

| Lubricating oil capacity | L | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| battery capacity | KW | 23 | 23 | 23 | 23 | 23 | 23 | 36 | 36 | 36 |

| coolant capacity | L | 250 | 300 | 300 | 300 | 300 | 300 | 370 | 370 | 470 |

| Form factor | ||||||||||

| Machine weight (approx.) | T | 7.5 | 8.5 | 8.8 | 9.2 | 10.2 | 11 | 12.8 | 13.8 | 16 |

| Machine length (front and rear) | MM | 2900 | 2900 | 2900 | 3000 | 3050 | 3050 | 3300 | 3300 | 3600 |

| Machine width (left and right) | MM | 3300 | 3550 | 3850 | 3950 | 4050 | 4250 | 4300 | 4650 | 5400 |

| Machine height (maximum) | MM | 2900 | 2900 | 2900 | 3100 | 3100 | 3100 | 3300 | 3300 | 3400 |

| Machine height (minimum) | MM | 2500 | 2500 | 2500 | 2650 | 2650 | 2620 | 2900 | 2900 | 3000 |

| Chip removal method (optional) | / | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate | single chain plate |

| Chip removal method (optional) | / | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw | Twin screw |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды