- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

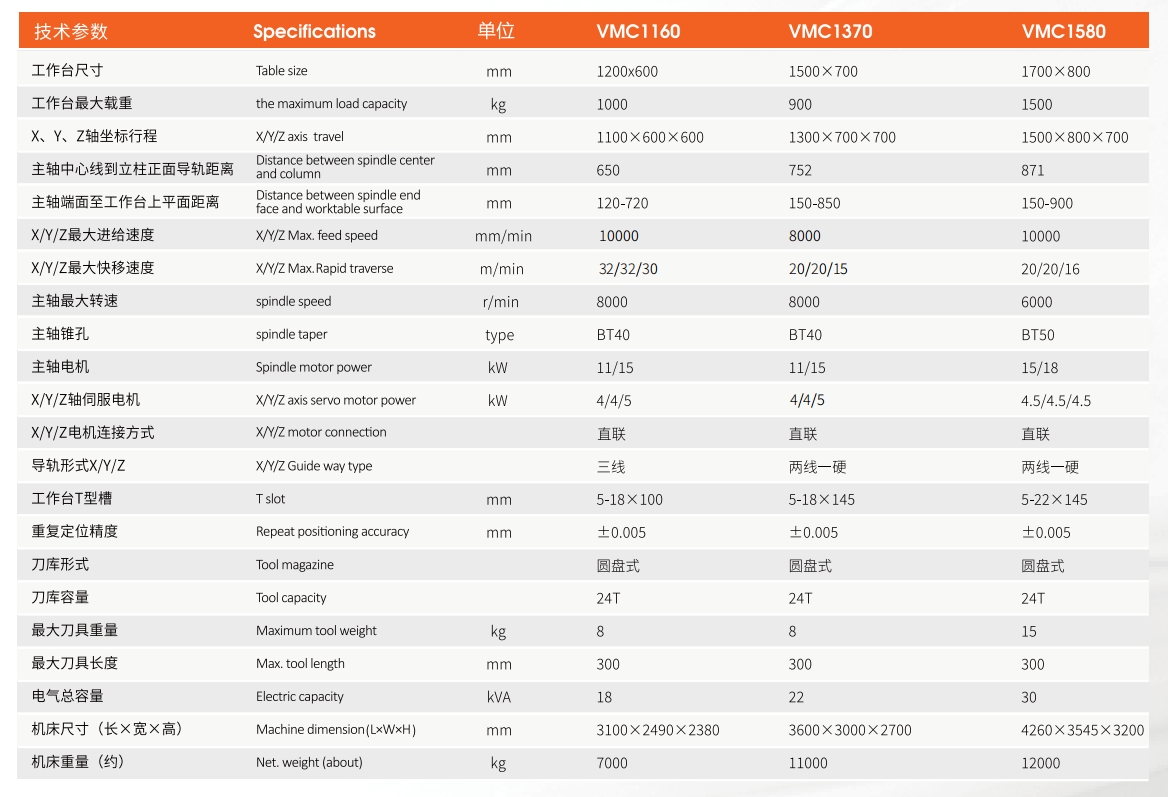

Automotive mold processing center VMC1160

VMC1160 is a CNC vertical machining center widely used in the automotive mold manufacturing industry....

VMC1160 is a CNC vertical machining center widely used in the automotive mold manufacturing industry. The following are the general characteristics of this machining center and its application in automotive mold processing:

1. High-precision processing: VMC1160 has high-precision processing capabilities and can meet the strict requirements for size and surface quality in automotive mold manufacturing.

2. Rigid structure: This kind of machining center usually has a solid machine tool structure and a highly rigid spindle, which can withstand the vibration and load when processing complex parts, ensuring processing accuracy and surface quality.

3. Multi-axis control: VMC1160 may have multi-axis control functions, allowing it to achieve three-dimensional processing of complex mold parts.

4. High-speed cutting: This kind of machining center is usually equipped with a high-speed spindle and a fast tool changing system, which can achieve high-speed cutting and improve production efficiency.

5. CAD/CAM integration: VMC1160 can be integrated with CAD/CAM software to make the conversion between design and processing more seamless, improving production efficiency and processing accuracy.

6. Automation functions: Some VMC1160 machining centers may be equipped with automation functions, such as automatic tool changing, automatic workpiece loading and unloading, etc., to improve production efficiency and reduce manual intervention.

7. Wide range of applications: VMC1160 machining center can process various materials, including steel, aluminum alloy, plastic, etc., and is suitable for various process requirements in automobile mold manufacturing.

8. Quality control and monitoring: This kind of machining center may be equipped with an online monitoring and quality control system, which can monitor key parameters in the machining process in real time and conduct quality inspection of processed parts.

In general, the VMC1160 machining center plays an important role in automotive mold manufacturing. Through its high precision, high efficiency and flexibility, it can meet the needs for complex parts processing in automotive mold manufacturing and improve production efficiency and product quality.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды