- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

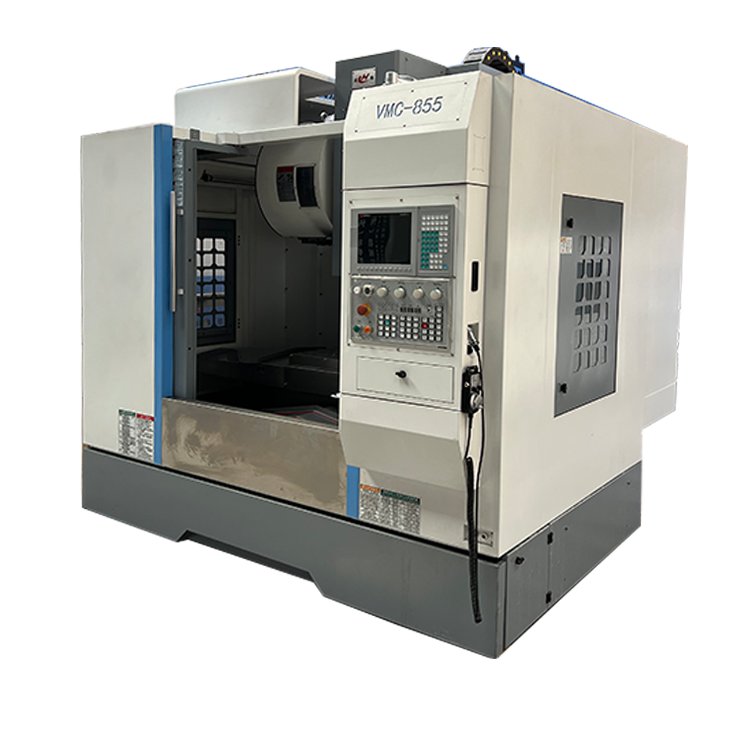

Machining center high speed processing mold

CNC machining center is a highly automated machine tool with efficient, high-precision and high-speed processing capabilities....

CNC machining center is a highly automated machine tool with efficient, high-precision and high-speed processing capabilities. It is widely used in mold manufacturing, aerospace, automotive, medical equipment and other industries, and can greatly improve processing efficiency and ensure high product quality.

This CNC machining center uses advanced technology and design to ensure stability during high-speed rotation and high-precision machining. Its main features include:

High-precision processing: The equipment uses high-precision bearings and transmission systems to ensure micron-level precision control during the processing process. In addition, it is equipped with a high-precision measurement and detection system that can monitor and correct errors in real time during the processing process, further improving the accuracy of the product.

High-speed spindle: The spindle speed of this CNC machining center can reach tens of thousands of revolutions per minute, which can quickly complete various cutting and milling operations. The use of high-speed spindles can not only improve processing efficiency, but also reduce thermal errors and vibration, thereby better ensuring processing quality. High degree of automation: The equipment is equipped with an advanced CNC system, which can realize automated programming, processing and inspection. The operator only needs to input the corresponding parameters and programs to complete the entire processing process, which greatly reduces manual intervention and operation difficulty.

Multi-axis linkage: This CNC machining center supports multi-axis linkage processing, and can control multiple tool axes at the same time for complex three-dimensional surface processing. This enables it to complete a variety of complex mold and component processing tasks.

Safe and reliable: This equipment is designed with the operator's safety and comfort in mind. It is equipped with protective devices and emergency stop functions to ensure that operators can quickly stop the machine and protect their own safety when encountering danger. At the same time, the equipment also adopts an energy-saving and environmentally friendly design, reducing energy consumption and emissions.

In short, this CNC machining center is widely used in various industries due to its advantages such as high precision, high speed, and automation. By using this equipment, companies can improve production efficiency, reduce costs, and ensure product quality, thereby standing out in the fierce market competition. If you are looking for a high-performance CNC machining center, this product is undoubtedly your best choice.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды