- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

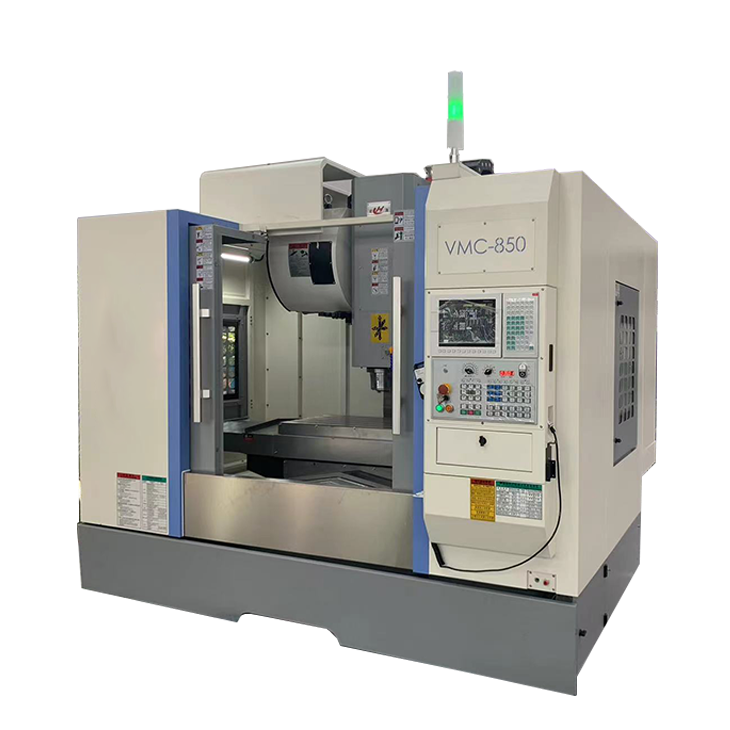

CNC machining center improves efficiency

Improving the efficiency of CNC machining centers is one of the key goals in the manufacturing industry....

Improving the efficiency of CNC machining centers is one of the key goals in the manufacturing industry.

1. Optimize program and tool path: By optimizing CNC program and tool path, unnecessary movement and idle time can be reduced, and cutting efficiency can be improved.

2. Automation and intelligence: Introduce automation systems and intelligent technologies, such as automatic tool changing systems, automatic workpiece clamping systems, etc., to reduce manual intervention and improve production efficiency.

3. Reasonably arrange the production plan: Develop a reasonable production plan to ensure that the CNC machining center is in optimal operating condition. Consider factors such as workpiece priority and process routes.

4. Quick tool change: Use a quick tool change system to reduce tool change time and improve production continuity.

5. Preventive maintenance: Carry out regular equipment maintenance and upkeep to avoid equipment failures and improve equipment reliability.

6. Training operators: Provide operator training so that they can skillfully operate the CNC machining center and maximize equipment performance.

7. Real-time monitoring and feedback: Use the monitoring system to monitor the operating status of the CNC machining center in real time, discover problems in time and take measures.

8. Material management: Ensure timely supply of raw materials to avoid production interruption due to insufficient raw materials.

9. Energy saving and environmental protection: Optimize the processing technology, reduce energy consumption, and achieve energy-saving and environmentally friendly production.

10. Invest in new technologies: Consider introducing new CNC technology and innovative equipment to improve production efficiency and machining accuracy.

11. Quality control: Emphasize quality control, reduce the defective rate, avoid repeated processing, and improve output quality.

12. Production data analysis: Use data analysis tools to analyze production data, find potential optimization points, and make more scientific production decisions.

By applying a combination of these strategies, the manufacturing industry can achieve higher levels of production and competitiveness while improving CNC machining center efficiency.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды