- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

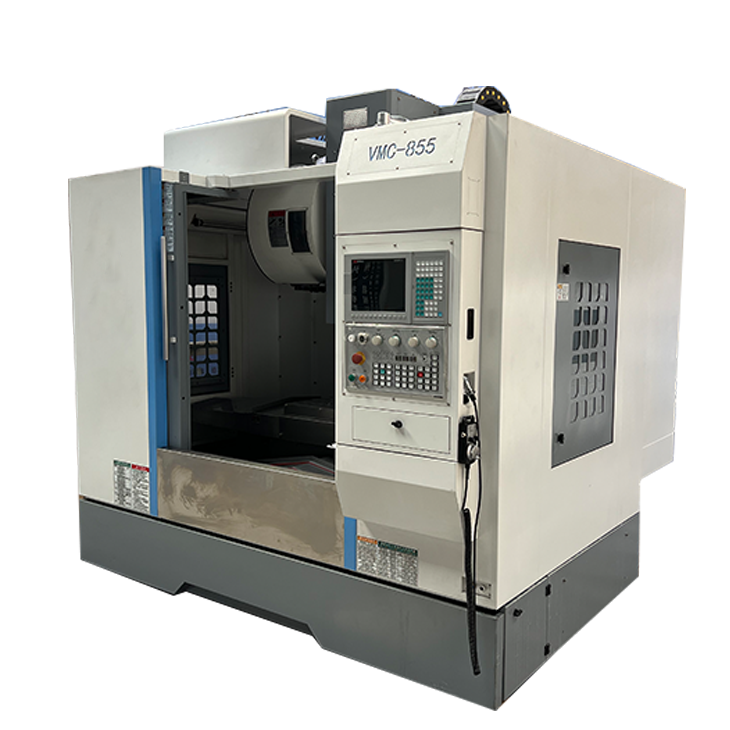

Fully automatic CNC vertical machining center

CNC machining center is a highly automated mechanical equipment used for precision machining....

CNC machining center is a highly automated mechanical equipment used for precision machining. Here are some features and functions about this machine:

1. Vertical design: The design of this CNC machining center is vertical, and the workpiece is usually processed in the vertical direction when processing. This design of CNC machining center makes the machining process more stable, easier to remove chips, and helps to improve machining efficiency.

2. CNC system: The CNC machining center is equipped with an advanced CNC system that can receive processing programs and convert them into instructions executable by the machine tool. CNC machining center operators can program to control various movements and operations of the machine tool.

3. Full automation: This CNC machining center has a high level of automation and can realize functions such as automatic tool change, automatic clamping of workpieces, automatic measurement and compensation. This enables the CNC machining center to continuously perform processing operations without operator intervention, improving production efficiency and processing accuracy.

4. Multi-axis motion: CNC machining centers usually have the capability of multi-axis motion. This multi-axis motion enables the machine tool to achieve more diverse processing operations in complex processing tasks.

5. Wide application: This CNC machining center is suitable for processing various materials, including metal, plastic, wood, etc. CNC machining centers are widely used in aerospace, automobile manufacturing, mold manufacturing, medical equipment manufacturing and other industries.

6. High-precision processing: CNC machining center vertical fully automatic machine tools have high machining accuracy and repeatability. CNC machining centers can complete the processing of complex parts in a short time and ensure the consistency of processing quality.

7. Friendly operating interface: This CNC machining center is usually equipped with an intuitive and friendly operating interface. CNC machining center operators can enter instructions, adjust parameters, etc. through the touch screen or keyboard to facilitate operation and control of the machine tool.

To sum up, CNC machining center is one of the very important processing equipment in modern manufacturing industry. The high degree of automation and precision processing capabilities of CNC machining center provide important support for production in various industrial fields.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды