- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

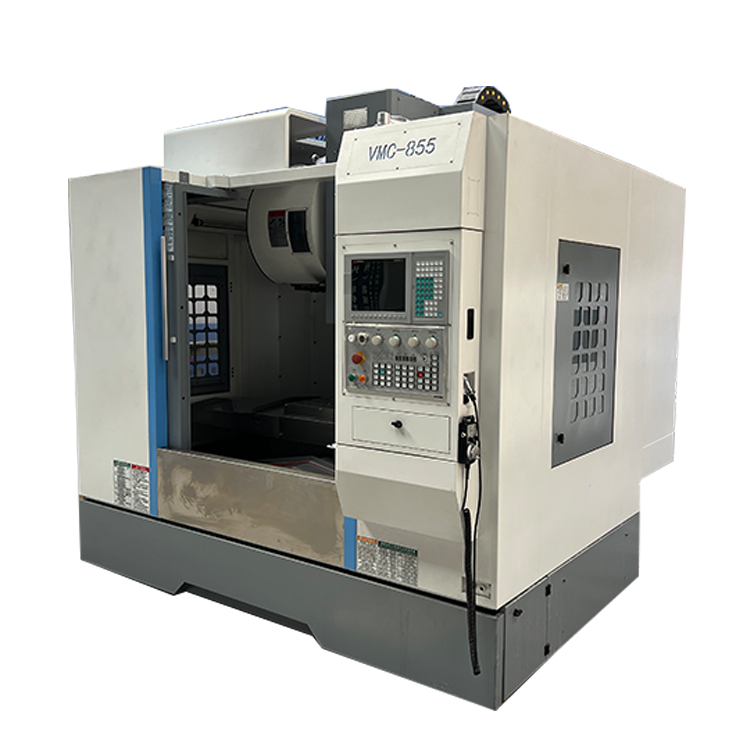

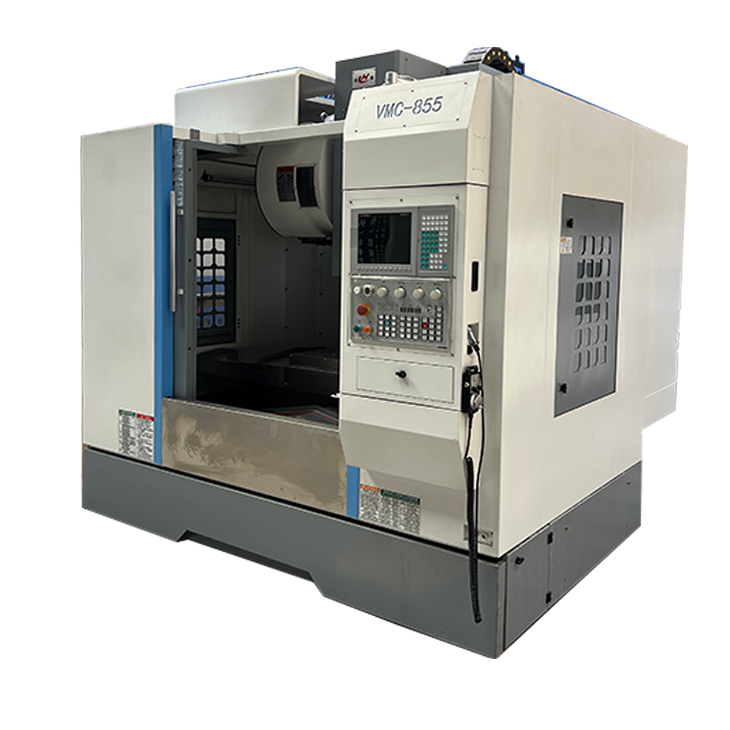

CNC vertical machining center with high repeatability

High repeatability is one of the important features of CNC vertical machining centers....

High repeatability is one of the important features of CNC vertical machining centers. This high-precision feature makes CNC vertical machining centers widely used in the manufacturing industry, especially in fields that require the production of high-precision parts, such as aerospace, automobile manufacturing, mold manufacturing, etc. Here are some key factors for high repeatability accuracy in CNC vertical machining centers:

1. High-precision guide rail system: CNC vertical machining centers usually use precision linear guide rail systems. This system has excellent wear resistance and high rigidity, and can ensure that the worktable maintains a high degree of accuracy during movement.

2. Stable spindle system: The spindle is a key component of the CNC machining center. The use of a high-precision spindle system can ensure the accuracy of tool rotation and movement. A high-speed, high-rigidity spindle facilitates precise cutting processes.

3. Precision servo system: The servo system controls the movement of each axis of the machine tool. The high-precision servo system can achieve precise positioning and high repeatability. Advanced control algorithms and encoder technology help ensure smooth and accurate movement.

4. Rigid machine tool structure: CNC vertical machining centers usually adopt a rigid machine tool structure, which helps reduce vibration and deformation and ensures that the machining center maintains a high degree of stability during work.

5. High-precision tool cutting system: A high-precision automatic tool changing system and tool sensors are used to ensure that the position and angle of the tool can be accurately matched after each tool change, thus improving the consistency and accuracy of cutting.

6. Advanced CNC system: The CNC system is the brain of the machining center. The advanced CNC system has a highly precise control algorithm and can adjust and monitor the movement of the machining center in real time, thereby improving machining accuracy.

7. Temperature stability: The design of CNC vertical machining centers takes into account the impact of temperature on machine tools, and takes measures such as temperature compensation and temperature control systems to ensure that high repeatability accuracy can be maintained under different working environments.

The combined effect of these factors enables CNC vertical machining centers to maintain a high degree of stability and accuracy over long periods of operation, making them suitable for manufacturing fields that require extremely high precision parts.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды