- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

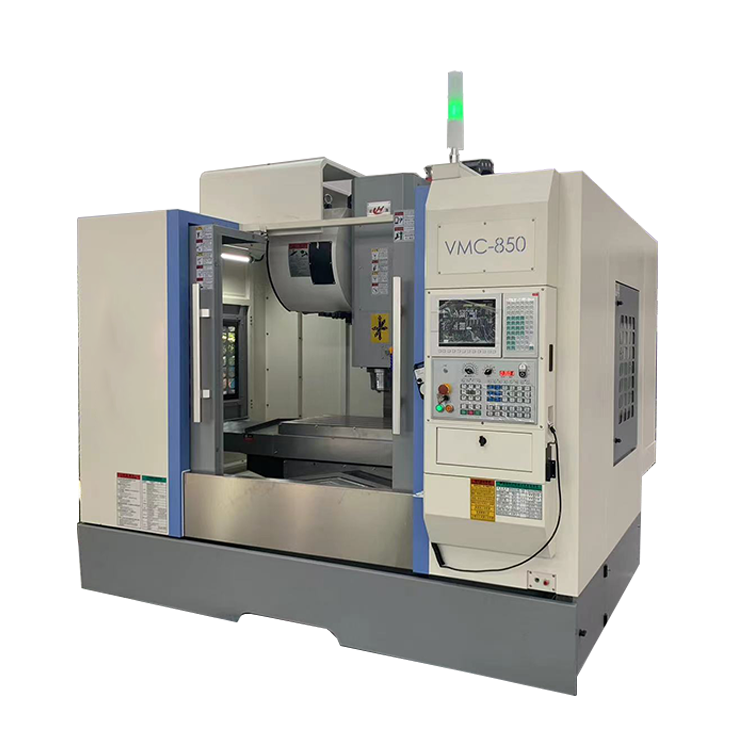

compact horizontal machining center

A compact CNC machining center is a smaller, more compact CNC machine tool designed specifically for space-constrained production environments or small and medium-sized businesses....

A compact CNC machining center is a smaller, more compact CNC machine tool designed specifically for space-constrained production environments or small and medium-sized businesses. This kind of machine tool retains the main functions of CNC machining centers, such as milling, drilling, boring, etc., but it occupies a smaller area and is suitable for installation in small workshops or limited work sites.

Features of compact CNC machining centers include:

1. Space optimization: This type of CNC machining center has a compact design and a small footprint, making it suitable for installation and use in limited spaces.

2. Efficient processing: Although the CNC machining center is small in size, the compact CNC machining center still has efficient processing capabilities and can quickly complete various processing tasks.

3. High precision: CNC machining centers adopt advanced CNC technology and servo systems, and compact CNC machining centers can maintain high machining accuracy and stability.

4. Easy to operate and maintain: This type of CNC machining center is usually designed to be intuitive and easy to operate and maintain. In addition, they are often equipped with modern diagnostic systems to facilitate rapid identification and resolution of problems.

5. Cost-effectiveness: Compact CNC machining centers are usually more affordable and suitable for small and medium-sized enterprises or users with limited budgets.

6. Versatility: Although CNC machining centers are compact, this type of CNC machining center can still be equipped with a variety of cutting tools and fixtures to adapt to different processing needs.

For small and medium-sized enterprises, compact CNC machining centers are a good choice because they can provide efficient, high-precision machining capabilities in a limited space while being relatively affordable.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды