- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

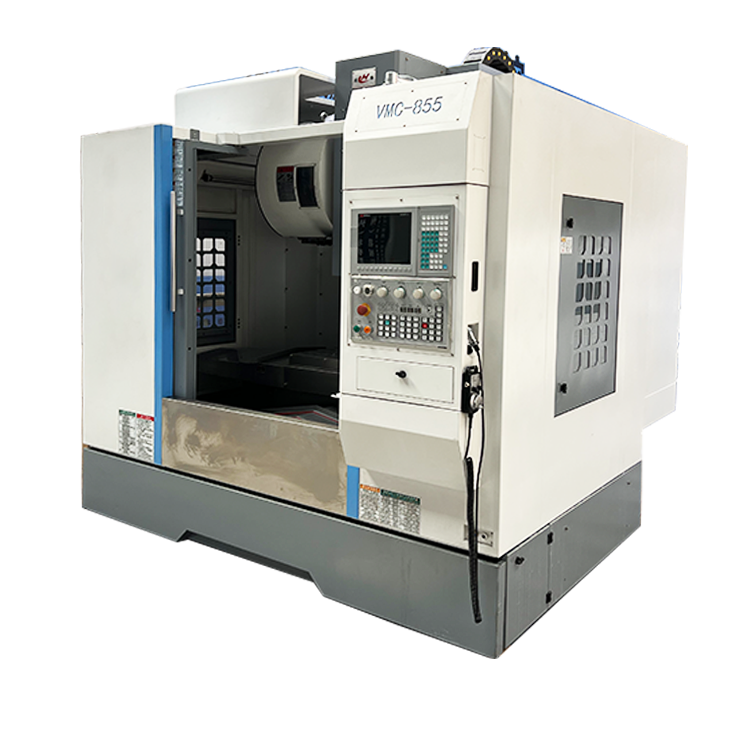

Hardware processing 855 vertical high precision machining center

855 vertical high-precision machining center usually refers to a CNC machine tool that is specially used for high-precision machining in the field of hardware machining, such as the machining of materials such as steel, aluminum alloy, and copper....

855 vertical high-precision machining center usually refers to a CNC machine tool that is specially used for high-precision machining in the field of hardware machining, such as the machining of materials such as steel, aluminum alloy, and copper. The following are the general characteristics and functions of this equipment:

1. High-precision machining: The 855 vertical high-precision machining center has high-precision machining capabilities and can achieve fine machining of hardware parts, including high-precision contour machining, hole machining, etc.

2. Vertical design: The machining center adopts a vertical design, the workpiece is fixed on the workbench, and the tool is processed vertically downward by the spindle, which is suitable for the machining of small parts and precision parts.

3. Multi-axis control: The 855 vertical high-precision machining center is usually equipped with a multi-axis CNC system, which can achieve precise control of multi-axis motion and realize the machining of complex parts.

4. Automatic tool changing system: In order to improve machining efficiency, the 855 vertical high-precision machining center is usually equipped with an automatic tool changing system, which can automatically change different types of tools according to the machining process.

5. High-speed processing: The 855 vertical high-precision machining center adopts a high-speed spindle and a fast tool change system, which can achieve high-speed processing and improve production efficiency.

6. Flexible processing: The 855 vertical high-precision machining center supports a variety of processing technologies, including milling, drilling, tapping, etc., which can meet the needs of different parts processing.

7. Stable and reliable: The 855 vertical high-precision machining center adopts a stable structural design and high-quality key components to ensure the stability and reliability of the machine tool and long-term stable operation.

8. Humanized operation interface: The 855 vertical high-precision machining center is equipped with an intuitive operation interface and a friendly human-computer interaction system. It is simple and convenient to operate, easy to learn and use.

In general, the 855 vertical high-precision machining center is a high-precision CNC machine tool specially used in the field of hardware processing. It has the characteristics of high precision, high efficiency, flexibility and stability, and can meet the needs of the hardware processing industry for precision parts processing.

| Machine model | VMC650 | VMC840 | VMC850 | VMC855 | VMC966 |

| Workbench size (mm) | 1000X400 | 1000X400 | 1000X500 | 1000X550 | 1100X550 |

| Maximum allowable load (Kg) | 400 | 300 | 500 | 500 | 600 |

| X-axis travel (mm) | 650 | 800 | 800 | 800 | 900 |

| Y-axis travel (mm) | 400 | 400 | 500 | 550 | 600 |

| Z-axis travel (mm) | 550 | 550 | 500 | 550 | 600 |

| T-slot | 3-18-120 | 3-18-140 | 5-18-108 | 5-18-90 | 5-18-100 |

| Distance from spindle center to Z-axis guide surface (mm) | 485 | 445 | 552 | 590 | 663 |

| Distance from spindle end face to worktable surface (mm) | 100-650 | 100-650 | 110-610 | 120-670 | 100-700 |

| Spindle taper hole | BT40-120 | BT40-120 | BT40-140 | BT40-150 | BT40-150 |

| Spindle speed (r/min) | 8000 | 8000 | 8000 | 8000 | 8000 |

| X/Y/Z rapid movement (m/min) | 48/48/48 | 30/30/18 | 48/48/48 | 48/48/48 | 48/48/48 |

| Machine weight (Kg) | 3800 | 3200 | 5300 | 5500 | 5600 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды