- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

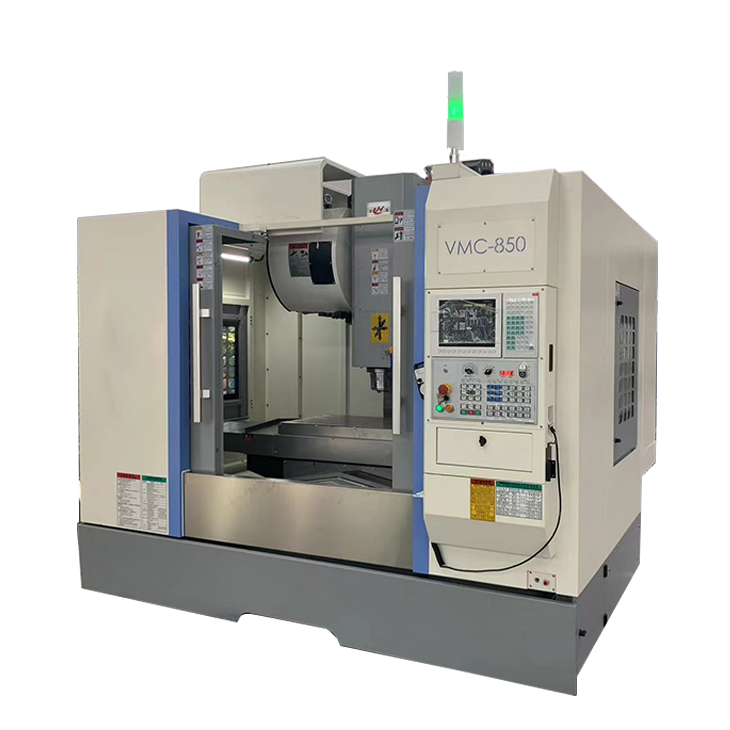

Heavy cutting machining center

A heavy cutting machining center is a machine tool equipment specially used for cutting large or heavy parts....

A heavy cutting machining center is a machine tool equipment specially used for cutting large or heavy parts. The heavy-cutting machining center has strong cutting capabilities and a high-rigidity structure, which can efficiently complete heavy-cutting tasks and improve production efficiency.

Heavy cutting processing plays an important role in the field of large equipment manufacturing industry and is a key link to improve equipment processing efficiency. The heavy cutting machining center achieves high-quality heavy cutting processing by adopting designs such as a strong and highly rigid bed, large-diameter spindle bearings, and an optimized structural layout.

This heavy-duty cutting machining center can be widely used in machinery manufacturing, automobiles, hydraulics, engineering machinery and other industries, and can process various large or heavy parts efficiently and accurately. For example, heavy cutting machining centers can be used to process machine tool structural parts, electric vehicle battery trays, motor casings, hydraulic pump bodies/valve bodies, engineering machinery box parts and other products.

The standard configuration of heavy cutting machining centers usually includes tool holders and high-rigidity spindles. These configurations enable them to easily handle various difficult-to-cut and heavy-cut workpieces and meet high-performance processing requirements in different material processing. At the same time, the rapid movement speed of each axis of the heavy-duty cutting machining center can reach a very high standard, ensuring that the equipment can operate at high speed and further improving production efficiency.

In addition, heavy cutting machining centers also have a high level of automation and intelligence. Through the CNC system, precise control of the processing process can be achieved, human intervention can be reduced, and processing accuracy and stability can be improved. At the same time, the heavy cutting machining center can also perform online monitoring and fault warning to promptly discover and solve potential problems to ensure the continuous and stable operation of the equipment.

In short, the heavy cutting machining center is a powerful, efficient and flexible machine tool equipment, which is of great significance for improving the efficiency and quality of heavy cutting processing. In the context of the transformation, upgrading and high-quality development of the manufacturing industry, it will continue to play an important role in promoting the development and progress of related industries.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды