- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

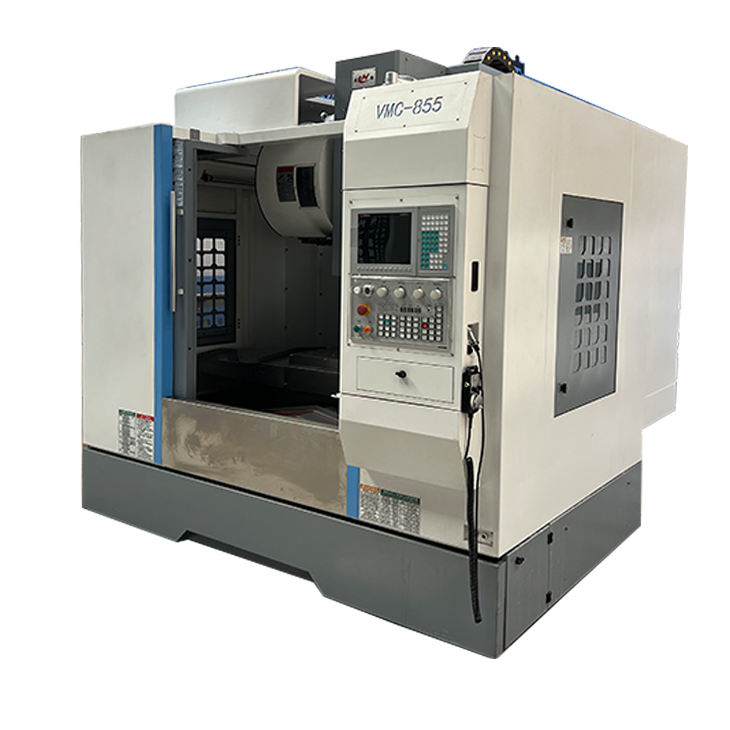

High-efficiency compact CNC machining center

Machining center is an indispensable and important equipment in the modern manufacturing field....

Machining center is an indispensable and important equipment in the modern manufacturing field. Its superior processing efficiency and stability make it an important part of industrial manufacturing. With the continuous development of technology, machining centers have developed from the original single machine tool to multiple forms such as multi-axis linkage and five-sided processing. Their application scope has also been further expanded, and they are widely used in high-precision manufacturing fields such as aviation and automobiles.

High efficiency and stability are one of the core advantages of machining centers. The precision CNC system ensures high precision, high speed and high efficiency in the processing process. By clamping multiple workpieces at one time and performing multi-stage processing at the same time, very complex forms can ultimately be processed, greatly improving processing efficiency. In addition, the cooperation of various auxiliary tools ensures the stability of the cutting effect and the consistency of the processing quality, thereby greatly reducing the process difficulty and the risk of quality problems in production.

Compact design is another important feature of machining centers. As the technology of manufacturers continues to improve, the size and weight of machining centers are gradually reduced, and the design becomes more flexible and adaptable. It occupies a small area, has low operating noise, and has good low-level vibration resistance, which can greatly reduce the body deformation and part failure rate of the machining center. There are also some machining centers that adopt a fully enclosed body structure that can even work normally in various complex environments.

In addition, CNC machining centers can also implement a variety of automation functions, such as automatic tool replacement, automatic tracking and calibration, etc. These automation functions allow the machining center to automatically handle some complex tasks, greatly improving the efficiency of industrial production. At the same time, these functions also greatly improve the safety and reliability of the machining center and reduce damage to the equipment due to human factors.

In short, the machining center is an indispensable and important equipment in modern manufacturing. Its superior technical advantages can greatly improve industrial production efficiency, effectively shorten the production cycle and reduce production costs. With the continuous development of science and technology and the continuous introduction of new equipment, machining centers will play an extremely important role in future industrial production.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды