- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

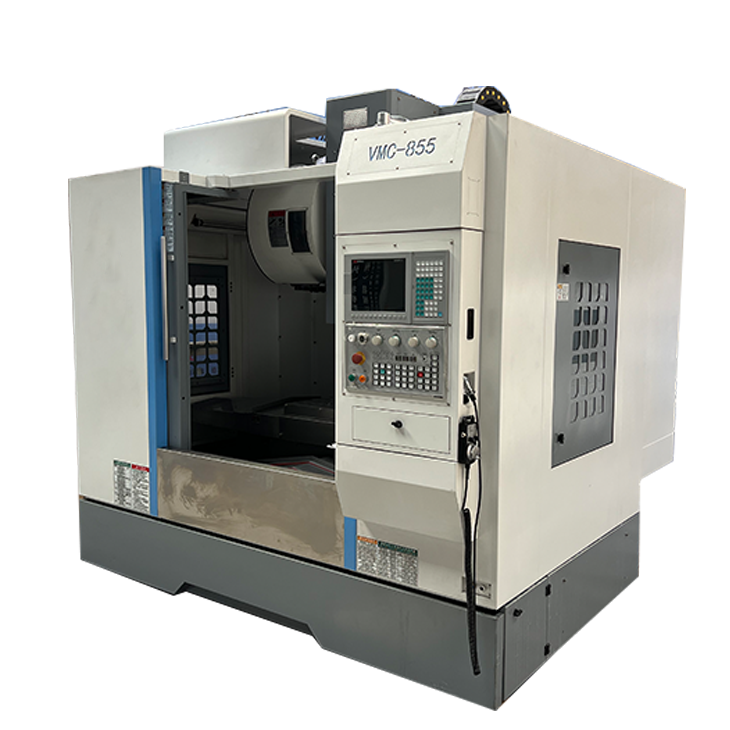

High precision mold processing center

High-precision mold processing center is one of the important links in modern manufacturing industry. It is responsible for the mold manufacturing tasks required to manufacture various products....

High-precision mold processing center is one of the important links in modern manufacturing industry. It is responsible for the mold manufacturing tasks required to manufacture various products. In today's era of continuous technological advancement, high-precision mold processing centers have become an indispensable part of modern manufacturing.

High-precision mold processing center refers to an important workstation that uses modern CNC technology and advanced equipment for mold processing. High-precision mold processing centers can not only manufacture various complex molds, but also complete processing tasks with high precision.

Features of high-precision mold processing center:

1. Advanced equipment: The high-precision mold processing center uses advanced CNC machine tools and processing equipment, which can complete mold processing tasks of various shapes and complexities.

2. High-precision processing: Due to the adoption of advanced CNC technology, the high-precision mold processing center can achieve high-precision processing and meet the various needs of customers for mold accuracy.

3. Fast delivery time: The high-precision mold processing center can quickly respond to customer needs and complete the manufacturing of molds in a short time, greatly shortening the product development cycle.

Application areas of high-precision mold processing centers:

1. Automobile manufacturing industry: High-precision mold processing centers play a vital role in the automobile manufacturing industry and can manufacture molds for various automobile parts, such as automobile body molds, engine parts molds, etc.

2. Electronic equipment manufacturing industry: High-precision mold processing center In the electronic equipment manufacturing industry, high-precision mold processing centers can manufacture various electronic equipment shell molds, printed circuit board molds, etc.

3. Plastic product manufacturing industry: High-precision mold processing centers can manufacture molds required for various plastic products, such as plastic box molds, plastic container molds, etc.

Advantages of high-precision mold machining center:

1. Improve production efficiency: The high-precision mold processing center adopts advanced CNC technology and equipment, which can complete mold processing in an efficient manner and improve production efficiency.

2. Ensure product quality: High-precision mold processing centers can achieve high-precision processing to ensure the accuracy and stability of the mold, thereby ensuring the quality of the product.

3. Save production costs: High-precision mold processing centers can quickly respond to customer needs, provide high-quality molds, and help customers reduce production costs.

To sum up, high-precision mold processing centers play an important role in modern manufacturing. Its emergence not only improves production efficiency and product quality, but also brings huge promotion to the development of various industries.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды