- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

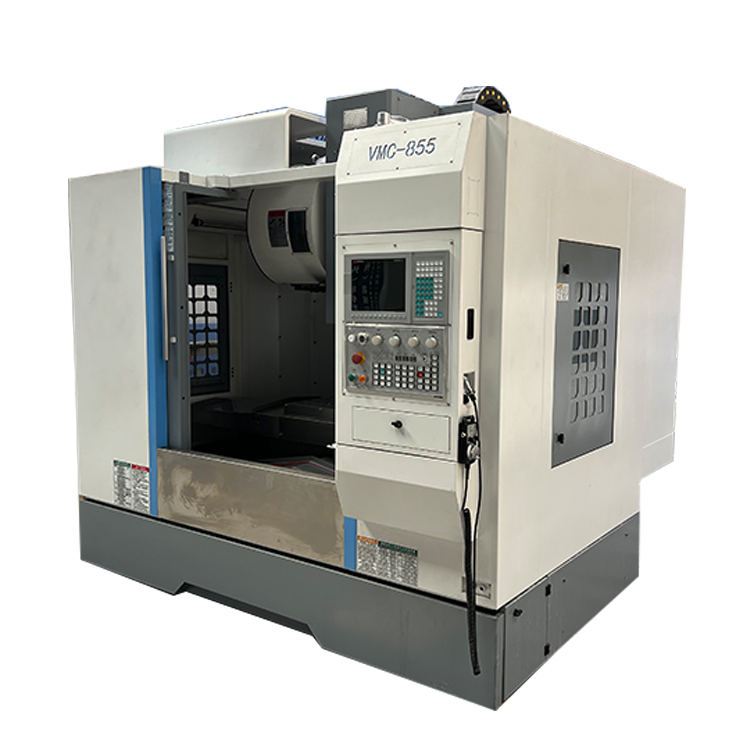

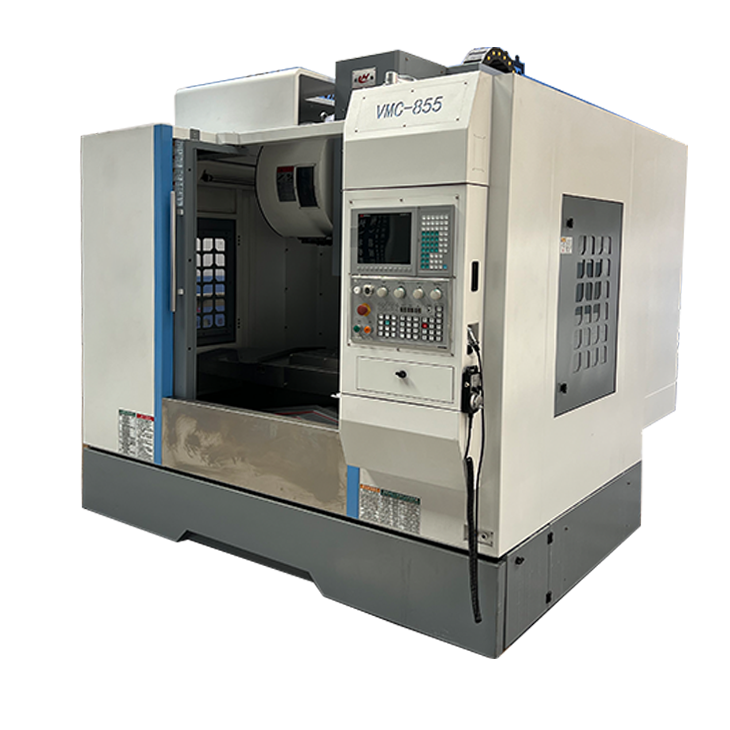

High speed machining center machine tool price

The high-speed machining center machine tool is a CNC machine tool that uses high-speed cutting technology for processing....

The high-speed machining center machine tool is a CNC machine tool that uses high-speed cutting technology for processing. High-speed machining center machine tools have higher cutting speeds and feed speeds, and can achieve higher efficiency and higher precision processing.

High-speed machining center machine tools usually have the following characteristics:

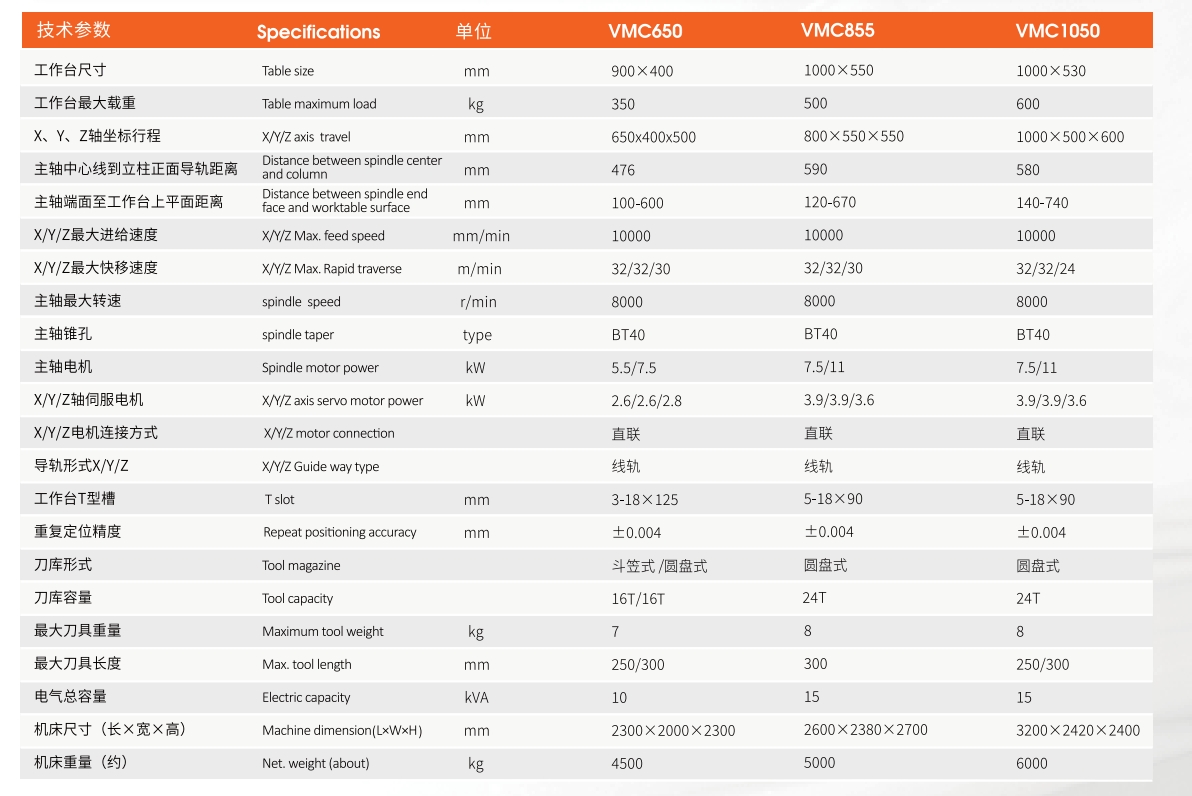

High-speed spindle: The spindle speed of high-speed machining center machine tools usually reaches tens of thousands of revolutions per minute or even higher, which results in smaller cutting forces and lower cutting temperatures, thereby achieving higher machining accuracy and surface quality.

Rapid feed: The feed speed of high-speed machining center machine tools is also much higher than that of traditional machine tools, which can shorten processing time and improve production efficiency.

High precision: High-speed cutting technology can reduce the impact of cutting force and cutting heat on the workpiece, thereby improving machining accuracy. At the same time, high-speed machining center machine tools are usually equipped with advanced control systems and servo systems, which can achieve higher positioning accuracy and repeated positioning accuracy.

Multifunctional processing: CNC vertical machining centers usually have multiple processing functions, such as milling, drilling, tapping, engraving, etc. This makes it suitable for a variety of process needs and capable of completing the processing of complex parts.

Wide scope of application: High-speed machining center machine tools are suitable for processing various materials, including metals, non-metals and composite materials. It can be used to process parts of various shapes such as planes, curved surfaces, holes and slots.

High-speed machining center machine tools are widely used in aviation, automobiles, molds, precision parts and other fields. It can greatly improve processing efficiency, processing accuracy and surface quality.

It should be noted that the use and maintenance of high-speed machining center machine tools requires professionals, and corresponding safety protection measures need to be equipped to ensure the safety and stability of the processing process.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды