- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

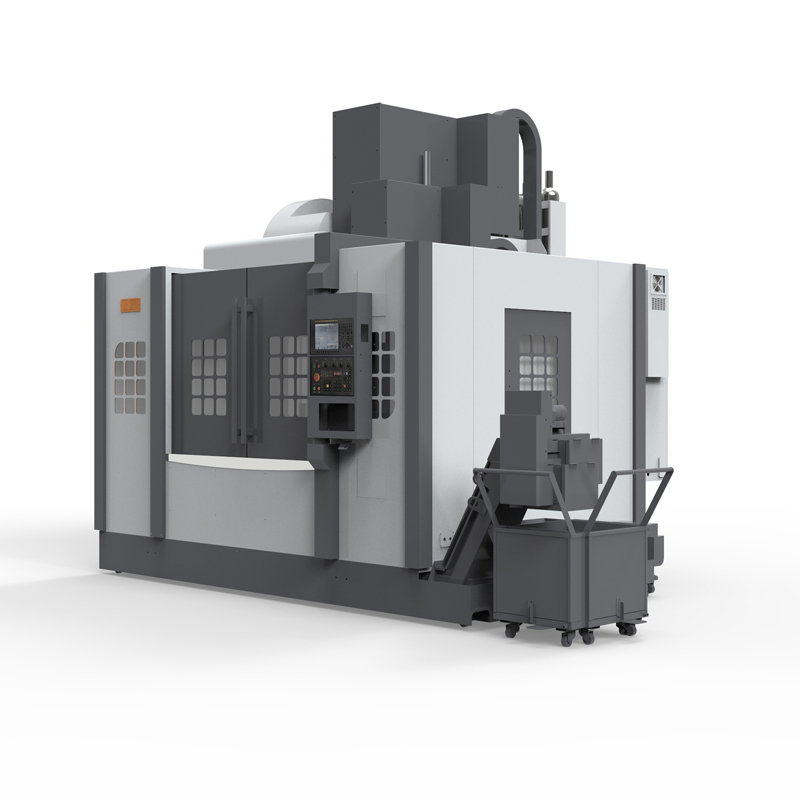

High speed machining CNC milling machine

High-speed machining CNC milling machine is a CNC equipment specially used for high-speed milling processing. It has the following characteristics:...

High-speed machining CNC milling machine is a CNC equipment specially used for high-speed milling processing. It has the following characteristics:

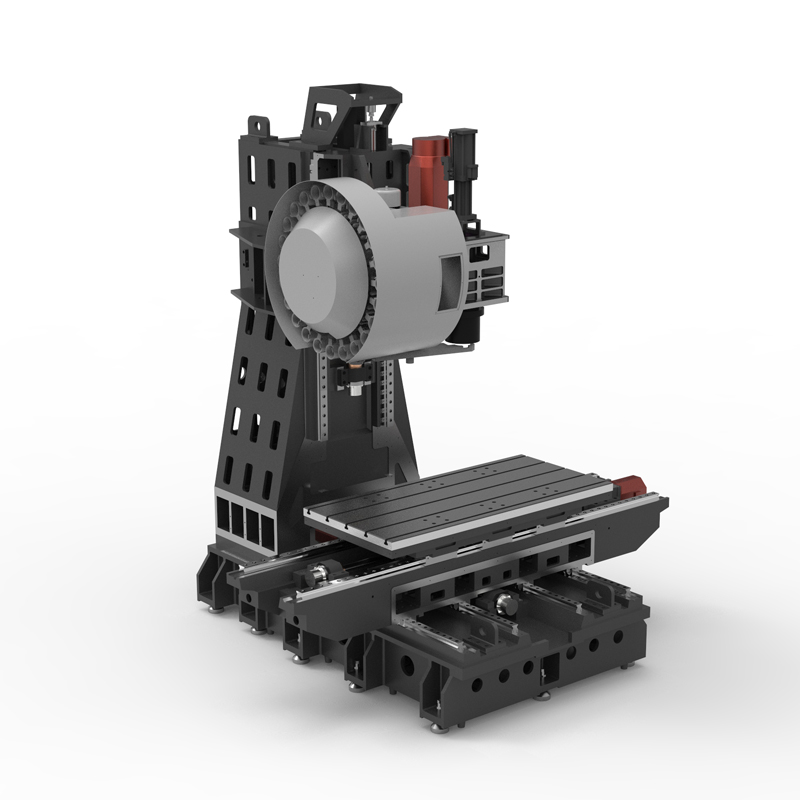

1. High-speed spindle: High-speed processing CNC milling machines are equipped with high-speed spindles, which usually reach thousands to tens of thousands of rpm, and are suitable for high-speed cutting.

2. High-speed feed: High-speed machining CNC milling machine has a fast and precise feed system, which can achieve high-speed and efficient processing.

3. High-rigidity structure: In order to adapt to the requirements of high-speed processing, this type of milling machine usually has a highly rigid bed and spindle structure to ensure processing accuracy and stability.

4. High-precision control system: The high-speed processing CNC milling machine is equipped with advanced CNC system and servo system, with high-precision position control and motion control capabilities.

5. Tool cooling system: High-speed CNC milling machines are usually equipped with a tool cooling system, which can effectively reduce cutting temperature and improve processing quality and tool life.

6. Automatic tool change system: High-speed CNC milling machines are usually equipped with automatic tool change systems, which can achieve rapid and automatic tool change and improve production efficiency.

7. Wide scope of application: High-speed CNC milling machines are suitable for processing workpieces of various materials, including metals, plastics, composite materials, etc., and have strong versatility.

High-speed machining CNC milling machines are widely used in aerospace, automobile manufacturing, mold manufacturing and other fields, and can meet the high demand for workpiece processing accuracy and efficiency.

| Specifications/model | unit | VT640A/B | VT840A/B | VT1050A/B | VT1350A/B | VT1650A/B |

| Work content | ||||||

| working desk size | MM | 700×400 | 1000×400 | 1100×500 | 1300×500 | 1700×500 |

| X-axis travel (left and right) | MM | 600 | 800 | 1000 | 1300 | 1600 |

| Y-axis travel (front and rear) | MM | 400 | 400 | 500 | 500 | 500 |

| Z-axis travel (up and down) | MM | 350 | 350 | 350 | 350 | 350 |

| Distance from spindle nose to work surface | MM | 100-500 | 100-500 | 100-500 | 100-500 | 100-500 |

| Z-axis heightening (optional) | MM | 300-650 | 300-650 | 300-650 | 300-650 | 300-650 |

| Maximum load of workbench | KG | 350 | 350 | 550 | 550 | 550 |

| Spindle specifications (Type A) | ||||||

| Spindle bore taper | BT | BT30 | BT30 | BT30 | BT30 | BT30 |

| Spindle structure | / | direct connection | direct connection | direct connection | direct connection | direct connection |

| Spindle speed | RPM | 20000 | 20000 | 20000 | 20000 | 20000 |

| Spindle horsepower | KW | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 |

| Spindle specifications (type B) | ||||||

| Spindle structure | / | direct connection | direct connection | direct connection | direct connection | direct connection |

| Spindle bore taper | BT | BT40 | BT30 | BT30 | BT30 | BT30 |

| Spindle speed | RPM | 12000 | 12000 | 12000 | 12000 | 12000 |

| Spindle horsepower | KW | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 |

| Feed content | ||||||

| G00 rapid feed | M/MIN | 48/48/48 | 48/48/48 | 48/48/48 | 48/48/48 | 48/48/48 |

| G01 cutting feed | MM/MIN | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Servo motor specifications | RPM | 3000 | 3000 | 3000 | 3000 | 3000 |

| Motor connection method | / | Direct | Direct | Direct | Direct | Direct |

| XY/Z ball screw specifications | MM | 28/3216 | 28/3216 | 32/4016 | 32/4016 | 32/4016 |

| X-axis rail specifications | MM | 30Ball | 30Ball | 35Ball | 35Ball | 35Ball |

| Y axis rail specifications | MM | 30Ball | 30Ball | 35Ball | 35Ball | 35Ball |

| Z axis rail specifications | MM | 35Ball | 35Ball | 35Ball | 35Ball | 35Ball |

| Precise shaft positioning | MM | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatable positioning precision | MM | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| Minimum move value | MM | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Tool magazine system | ||||||

| Tool magazine structure | PCS | Clamp type | Clamp type | Clamp type | Clamp type | Clamp type |

| Servo tool magazine capacity | T | 21 | 21 | 21 | 21 | 21 |

| Tool changing time T-T | MIN | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Maximum tool capacity | KGS | 6 | 6 | 6 | 6 | 6 |

| Oil and gas pressure system | ||||||

| air pressure | KG | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 | 6.5-8 |

| Lubricating oil capacity | L | 4 | 4 | 4 | 4 | 4 |

| battery capacity | KW | 18 | 18 | 18 | 18 | 18 |

| coolant capacity | L | 220 | 220 | 250 | 250 | 250 |

| Form factor | ||||||

| Machine weight (approx.) | KG | 3200 | 3600 | 5500 | 6800 | 8000 |

| Machine length (front and rear) | MM | 1800 | 2000 | 2600 | 3400 | 4200 |

| Machine width (left and right) | MM | 1600 | 1600 | 2400 | 2400 | 2400 |

| Machine height (maximum) | MM | 2500 | 2500 | 2700 | 2700 | 2700 |

| Machine height (minimum) | MM | 2100 | 2100 | 2300 | 2300 | 2300 |

| Chip removal method | / | backlash | backlash | backlash | backlash | backlash |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды