- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

Machining center optional system high efficiency

When selecting a system for a machining center or CNC lathe to achieve high efficiency, the following aspects can be considered:...

When selecting a system for a machining center or CNC lathe to achieve high efficiency, the following aspects can be considered:

1. CNC system selection:

Accuracy: For applications that require high-precision machining, you can choose a servo CNC system, which has higher accuracy than a stepper CNC system. For general part processing, servo CNC systems can usually meet the requirements.

Operation convenience: Choosing a CNC system with a user-friendly interface and easy programming can reduce operator training time and improve production efficiency.

2. Tool measurement:

Use a tool gauge or automatic tool length and radius measurement to obtain tool data quickly and accurately, reducing the time and errors of manual measurement.

3. Automatic workpiece measurement:

Equipped with dedicated contact sensors, laser probes and signal receivers, automatic measurement of workpieces can be achieved, reducing manual intervention and improving production efficiency.

Please note that the workpiece measurement function is generally suitable for measuring the position of the reference hole center or other reference point on the workpiece blank as the programming origin, and its accuracy usually does not exceed the positioning accuracy of the machine tool itself.

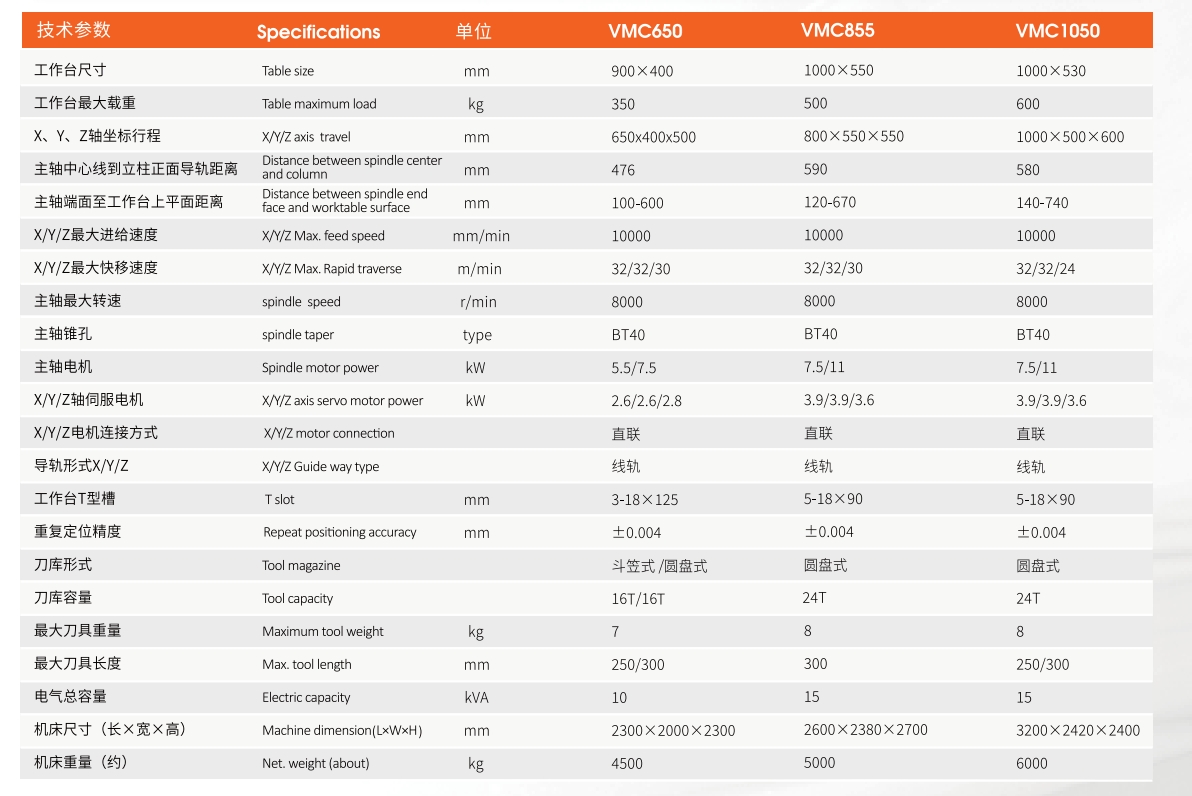

4. Machine tool parameter configuration:

Reasonably determine the main parameters of the machine tool according to the processing needs, such as the maximum processing diameter, maximum processing length, number of tool holder positions, etc., to ensure that the machine tool can meet production requirements.

Consider the positioning accuracy and repeatability of the machine tool to ensure the quality and consistency of machined parts.

5. Machine tool appearance protection:

Choose appropriate machine tool appearance protection methods, such as fully protected CNC lathes, to ensure that the machine tool can operate stably in harsh working environments and extend its service life.

To sum up, by rationally selecting the CNC system, optimizing tool measurement and compensation, realizing automatic workpiece measurement, rationally configuring machine tool parameters, and strengthening machine tool appearance protection, the processing efficiency and quality of machining centers or CNC lathes can be effectively improved.

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды