- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

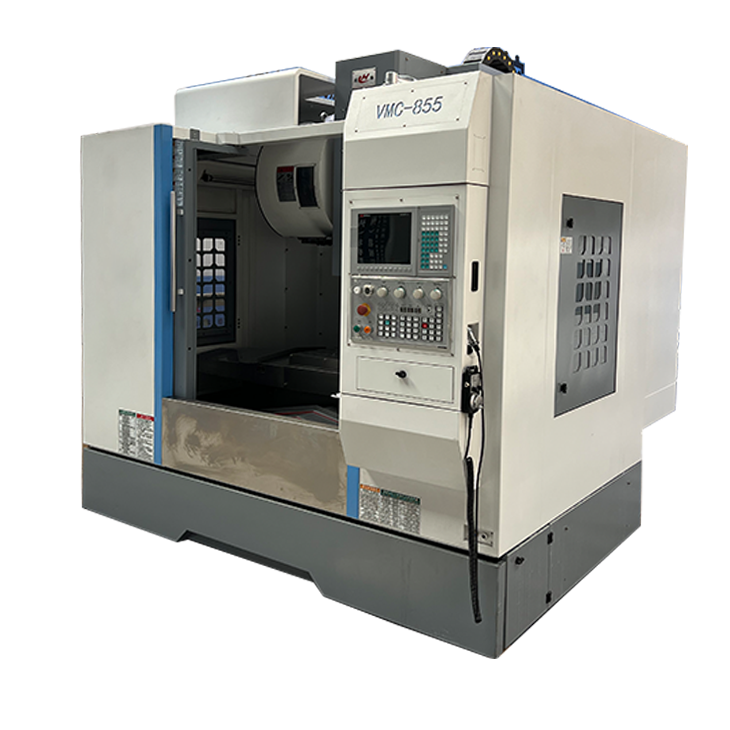

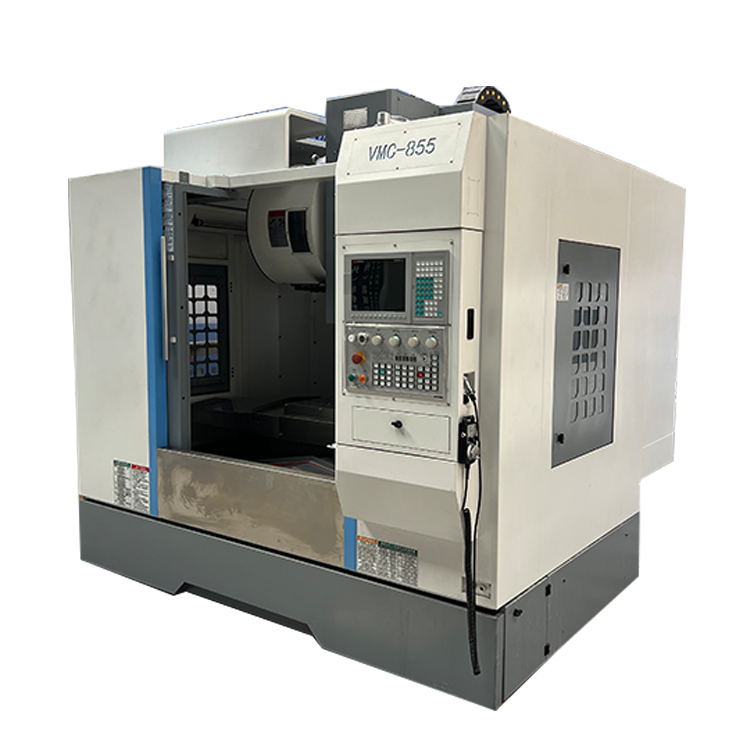

Machining center free programming high precision

The high precision of programming-free machining center usually refers to the use of advanced CNC systems and machining technology, which can achieve high-precision machining without manual programming....

The high precision of programming-free machining center usually refers to the use of advanced CNC systems and machining technology, which can achieve high-precision machining without manual programming. The high precision of programming-free machining center usually has the following characteristics and advantages:

1.CAD/CAM integration: Programming-free machining center usually integrates CAD (computer-aided design) and CAM (computer-aided manufacturing) systems, and can generate machining programs directly from CAD models without manual programming.

2. Automated programming: Through the CAD/CAM system, the machining center can automatically generate machining paths and tool paths, realize automated programming, greatly simplify the operation process, and improve production efficiency.

3. High-precision machining: Programming-free machining centers are usually equipped with high-precision CNC systems and precise mechanical structures, which can achieve high-precision machining and ensure the dimensional accuracy and surface quality of machined parts.

4. Intelligent tool management: The high precision of programming-free machining center is usually equipped with an intelligent tool magazine and tool management system, which can automatically select the appropriate tool according to the machining task, and perform tool compensation and replacement, which improves the stability and consistency of machining.

5. Online monitoring and optimization: Programming-free machining centers usually have online monitoring and optimization functions, which can monitor the status and parameters of the machining process in real time, and adjust and optimize as needed to ensure machining quality and efficiency.

6. User-friendliness: Programming-free machining centers usually have friendly user interfaces and operating systems, which are easy to operate, easy to learn and use, and reduce the training cost and time of operators.

In general, programming-free machining centers can achieve high-precision machining, simplify operating procedures, and improve production efficiency through technical means such as integrated CAD/CAM systems, automated programming, intelligent tool management, and online monitoring. It is one of the important equipment in modern manufacturing.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды