- Recommended news

-

System composition of CNC horizontal machining center

2024-06-18

-

A method to solve the problem of spindle shaking in CNC lathes

2024-06-15

-

In which industry is the most widely used CNC vertical lathe?

2024-06-04

-

How to clamp the workpiece on a CNC vertical lathe?

2024-05-29

-

CNC milling machine machining center commonly used accessories

2024-05-25

-

Steps for adjusting the turret of a CNC vertical lathe

2024-05-22

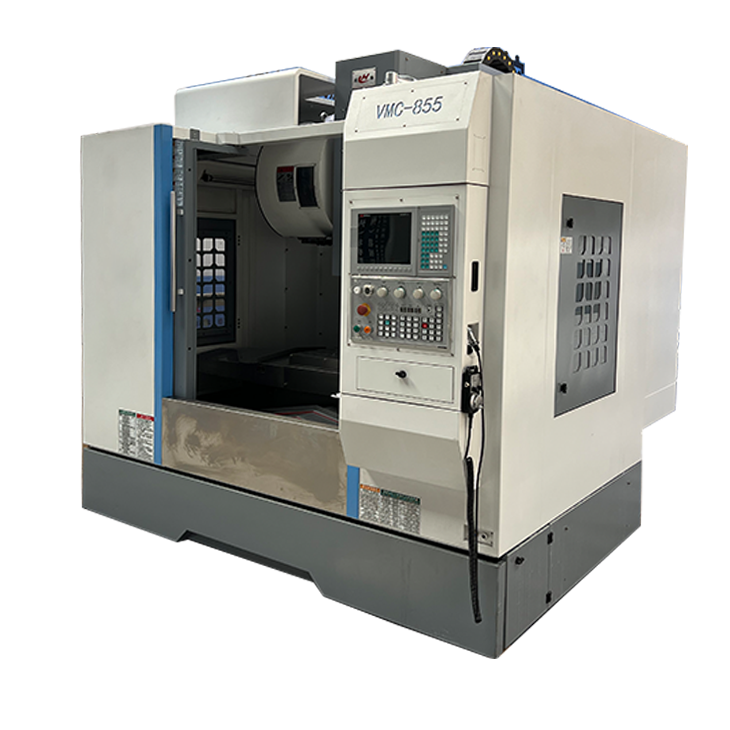

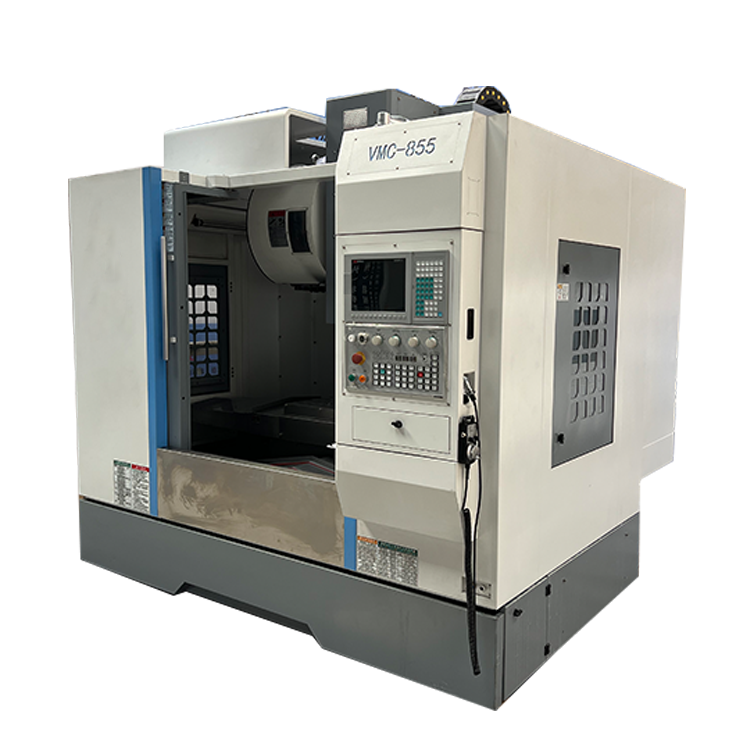

Machining Center Precision Mold Processing

A machining center refers to a machine tool that uses computer numerical control technology, which can achieve high-precision and high-efficiency processing tasks....

A machining center refers to a machine tool that uses computer numerical control technology, which can achieve high-precision and high-efficiency processing tasks. In the field of mold processing, this kind of machining center is usually used to manufacture various types of molds, including plastic molds, die-casting molds, injection molds, etc. The following are some characteristics of machining center CNC intelligent CNC machine tools in precision mold processing:

1. High-precision processing: The machining center has high-precision processing capabilities and can meet the high-precision processing requirements of complex molds. The machining center can ensure the dimensional accuracy, surface quality and geometric shape accuracy of the mold through precise CNC systems and advanced processing technology.

2. Complex shape processing: Machining center molds usually have complex geometric shapes and structures. The machining center has multi-axis control capabilities and can achieve complex shape processing tasks. Whether it is a surface with subtle curves or a concave and convex structure of varying shades, this machine can produce it with precision.

3. Automated processing: Machining centers are usually equipped with automatic tool changing systems, automatic workpiece measurement systems and automated processing process control functions. These automated features can improve production efficiency and reduce human intervention while ensuring consistent processing quality.

4. Intelligent technology: With the development of artificial intelligence and machine learning technology, machining centers have gradually become intelligent. For example, through intelligent processing algorithms and real-time monitoring systems, intelligent optimization and real-time adjustment of the processing process can be achieved to improve processing efficiency and quality.

5. Flexibility and customization: The machining center has strong flexibility and customization capabilities. The machining center can be customized and configured according to different mold processing needs. Whether it is small batch customization or mass production, this machine tool can meet the needs of different users.

In summary, machining centers have important application value in the field of precision mold processing, which can improve production efficiency, reduce costs, and ensure the stability and consistency of mold processing quality.

| Specifications | unit | VMC650 | VMC855 | VMC1050 |

| Table size | mm | 900x400 | 1000x550 | 1000x530 |

| Table maximum load | kg | 350 | 500 | 600 |

| X//Z axis travel | mm | 650x400x500 | 800x550x550 | 1000x500x600 |

| Distance between spindle centerand column | mm | 476 | 590 | 580 |

| Distance between spindle endface and worktable surface | mm | 100-600 | 120-670 | 140-740 |

| X//Z Max. feed speed | mm/min | 10000 | 10000 | 10000 |

| X//Z Max. Rapid traverse | m/min | 32/32/30 | 32/32/30 | 32/32/24 |

| spindle speed | r/min | 8000 | 8000 | 8000 |

| spindle taper | type | BT40 | BT40 | BT40 |

| Spindle motor power | kW | 5.5/7.5 | 7.5/11 | 7.5/11 |

| X//Z axis servo motor power | kW | 2.6/2.6/2.8 | 3.9/3.9/3.6 | 3.9/3.9/3.6 |

| X//Z motor connection | Direct | Direct | Direct | |

| X/Y/Z Guide way type | Line rail | Line rail | Line rail | |

| T slot | mm | 3-18x125 | 5-18x90 | 5-18x90 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Tool magazine | Hat type/disc type | disc type | disc type | |

| Tool capacity | 16T/16T | 24T | 24T | |

| Maximum tool weight | kg | 7 | 8 | 8 |

| MMax. tool length | mm | 250/300 | 300 | 250/300 |

| Electric capacity | kVA | 10 | 15 | 15 |

| Machine dimension(LxWxH) | mm | 2300x2000x2300 | 2600x2380x2700 | 3200x2420x2400 |

| Net. weight (about) | kg | 4500 | 5000 | 6000 |

English

English 日本語

日本語 한국어

한국어 Россия

Россия  Français

Français España

España عرب .

عرب .  Português

Português Deutsch

Deutsch भारत

भारत Нидерланды

Нидерланды